Glass fiber composite defect detecting method based on terahertz time-domain spectroscopy

A technology of terahertz time domain and glass fiber, which is applied in the direction of optical testing of flaws/defects, material analysis through optical means, and material analysis. Ease of acquisition and improved safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

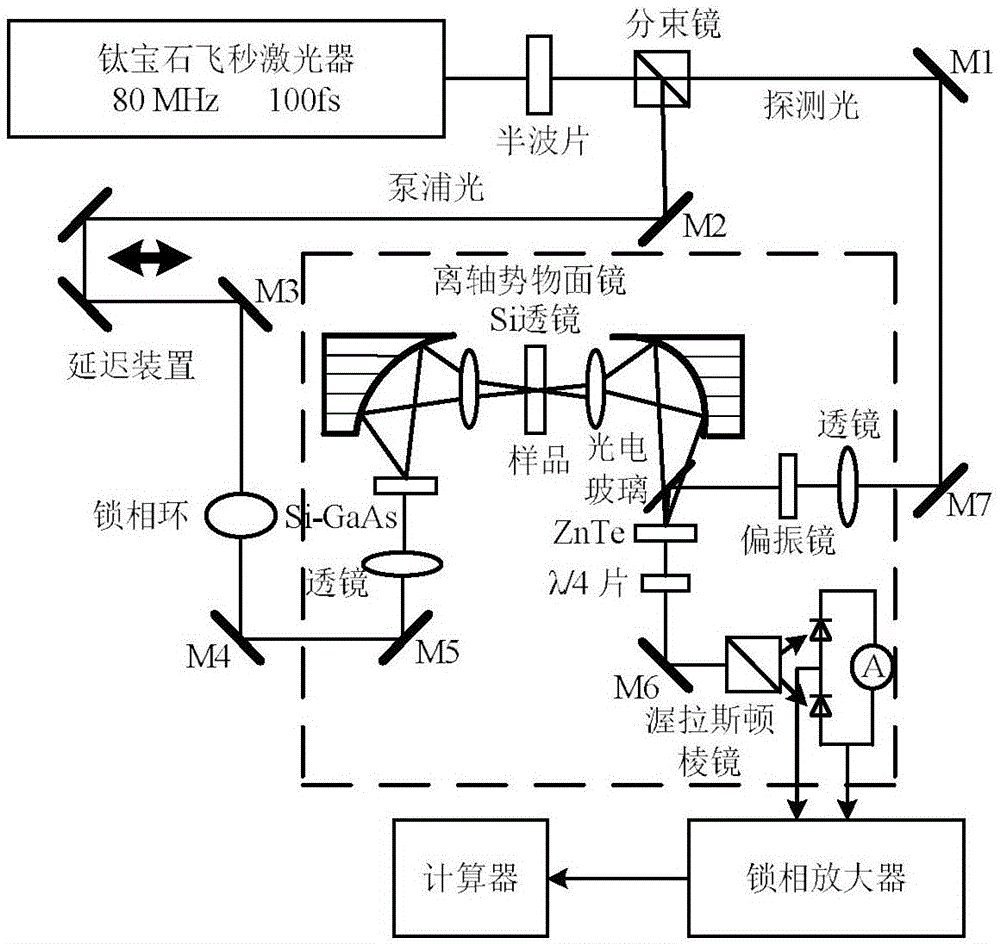

[0016] The glass fiber composite material defect detection method of the terahertz time-domain spectroscopy technology comprises the following steps:

[0017] (1) Under room temperature conditions, the terahertz optical path is covered in a box filled with nitrogen, and the relative humidity in the box is below 4.0%. The cut glass fiber sample is placed on the sample holder, and the signal-to-noise ratio is 1000dB. Under the condition that the spectral resolution exceeds 40 GHz, the terahertz wave probe scans the sample at a step of 0.1mm / time to 1mm / time, and obtains the terahertz time-domain transmission pulse of each scanning point of the sample.

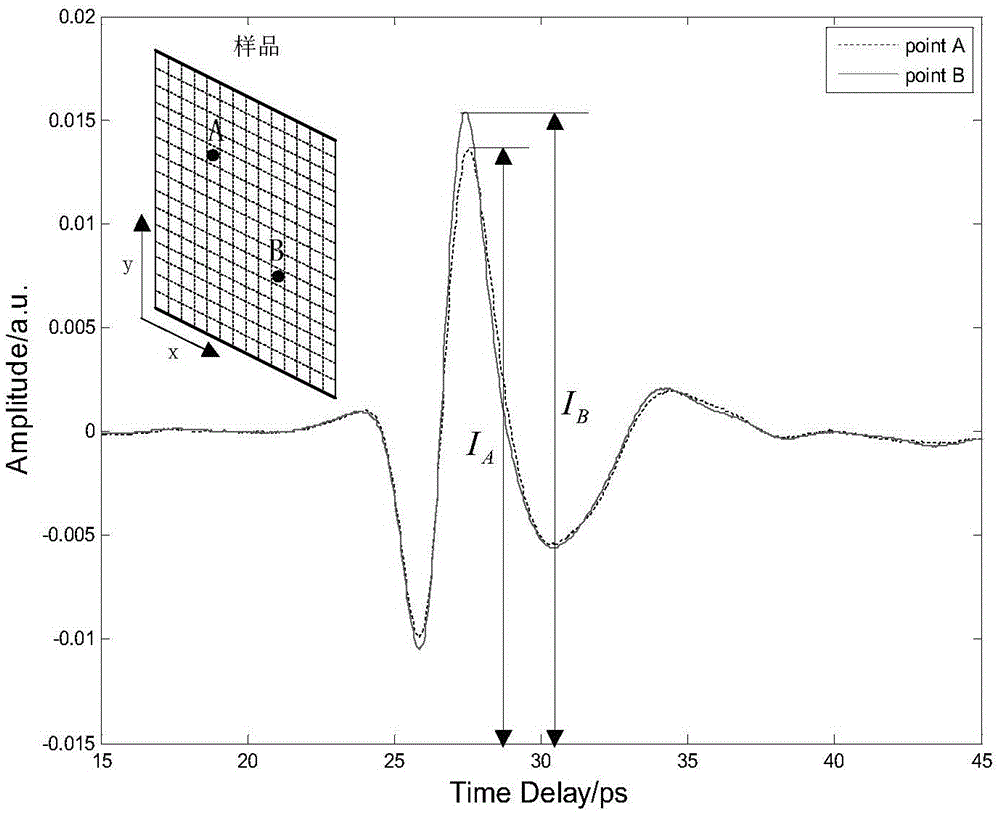

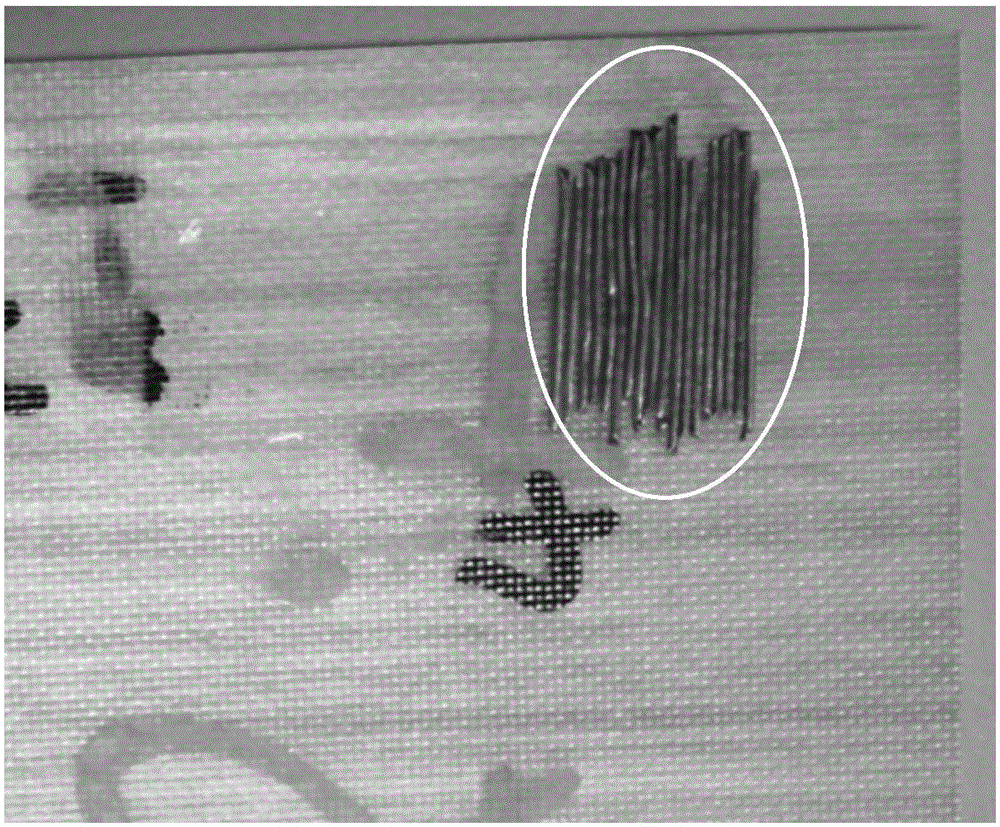

[0018] (2) Analyze the time-domain transmission pulse data obtained in step (1) to obtain the time-domain transmission pulse amplitude I of each scan point of the sample i , for all samples the time-domain pulse amplitude I i For comparison, the maximum value I of the sample time-domain pulse amplitude is obtained max =max(I 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com