Metal grid transparent conducting film, preparation method thereof and capacitive touch screen

A technology of capacitive touch screen and transparent conductive film, which is applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve the problems of inability to obtain metal mesh transparent conductive film in mass production, and achieve uniform line width , good visibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

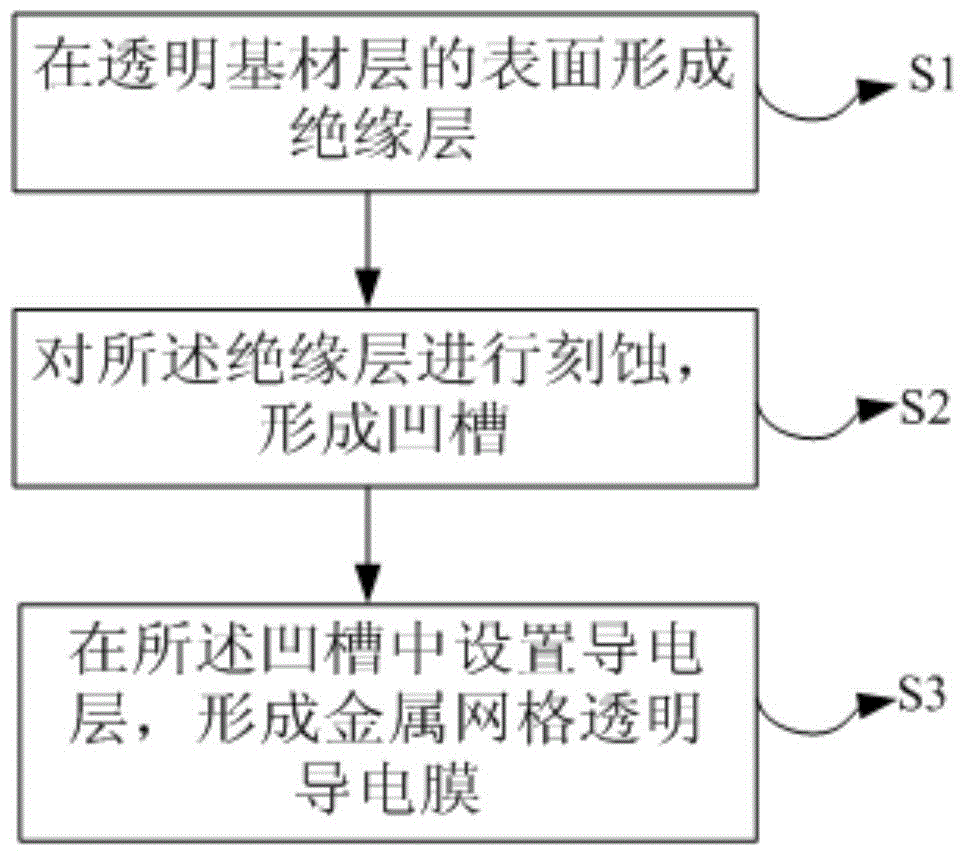

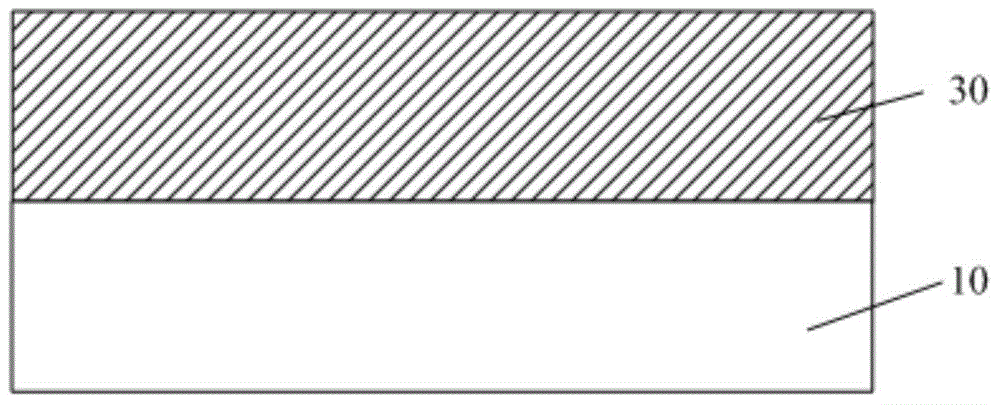

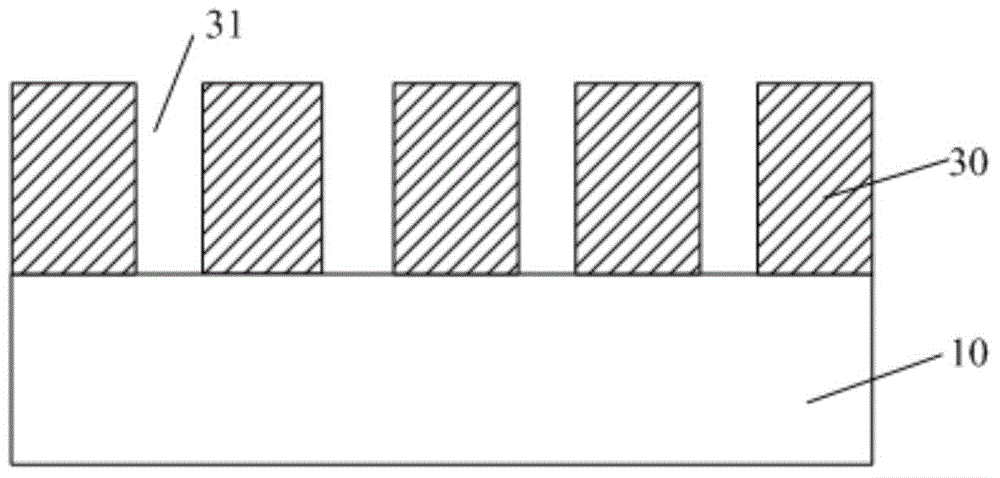

[0035] In a typical implementation of the present application, such as figure 1 As shown, a method for preparing a metal grid transparent conductive film is proposed, the method includes: step S1, forming an insulating layer 30 on the surface of the transparent substrate layer 10, such as figure 2 shown; step S2, for figure 2 The insulating layer 30 in the middle is etched to form a groove 31, such as image 3 shown; and step S3, the conductive layer 50 is set in the above-mentioned groove 31, forming Figure 4b The metal mesh transparent conductive film is shown.

[0036] In this method, an insulating layer 30 is first provided on the surface of the transparent substrate layer 10, and then it is etched to form a groove 31. The material of the insulating layer 30 is generally photosensitive glue, which is more dense than the material of the conductive layer 50. It is easy to form a fine structure, so the line width of the groove 31 formed by etching the insulating layer 3...

Embodiment 1

[0059] First, in Figure 7 The thickness shown is 1.5 μm on the second hardened protective layer 15, and the PCZ001 glue of DIC Company of Japan is wet-coated to obtain an insulating photosensitive glue layer with a dry film thickness of 10 μm. After exposure, the width of the non-hollowed part in the hollowed-out light-shielding plate is 5 μm, the width of the hollowed-out part is 100 μm, and the exposure amount is 800 mJ / cm2, so that the part of the insulating photosensitive glue layer that is not blocked by the light-shielding plate hardens and is shielded from light. The part shielded by the plate was not hardened, and an insulating layer was formed, and the thickness of the hardened part was 10 μm.

[0060] Then, use solvent MIBK (MethylIsobutylKetone, methyl isobutyl ketone) to perform wet etching on the structure of the insulating layer, remove the unhardened insulating photosensitive glue layer, form grooves and dry them.

[0061] Finally, silver paste was coated on t...

Embodiment 2

[0063] First, in Figure 7 The thickness shown is 1.5 μm, and the PCZ001 glue of DIC Company of Japan is set on the second hardened protective layer 15 to obtain an insulating photosensitive glue layer with a dry film thickness of 10 μm. , where the width of the non-hollowed out part in the hollowed-out visor is 5 μm, the width of the hollowed out part is 100 μm, and the exposure amount is 800 mJ / cm 2 , so that the part of the insulating photosensitive glue layer that is not covered by the light-shielding plate is hardened, and the covered part is not hardened, thereby forming an insulating layer, and the thickness of the hardened part is 10 μm.

[0064] Then, the solvent MIBK is used to perform wet etching on the structure forming the insulating layer, remove the unhardened glue, form grooves and dry them.

[0065] Finally, copper paste was coated on the surface of the structure from which the unhardened glue was removed, and after the copper paste was heated and hardened, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com