Preparation method of microstructure reinforcement reflective photocathode

A microstructure and reflective technology, which is applied in the manufacture of light-emitting cathodes, can solve problems such as difficulty in ensuring the uniformity and stability of photoelectric emission, unrealized preparation methods and technologies, and complex processes, so that the surface microstructure can be easily controlled. , Good uniformity of photoelectric emission and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

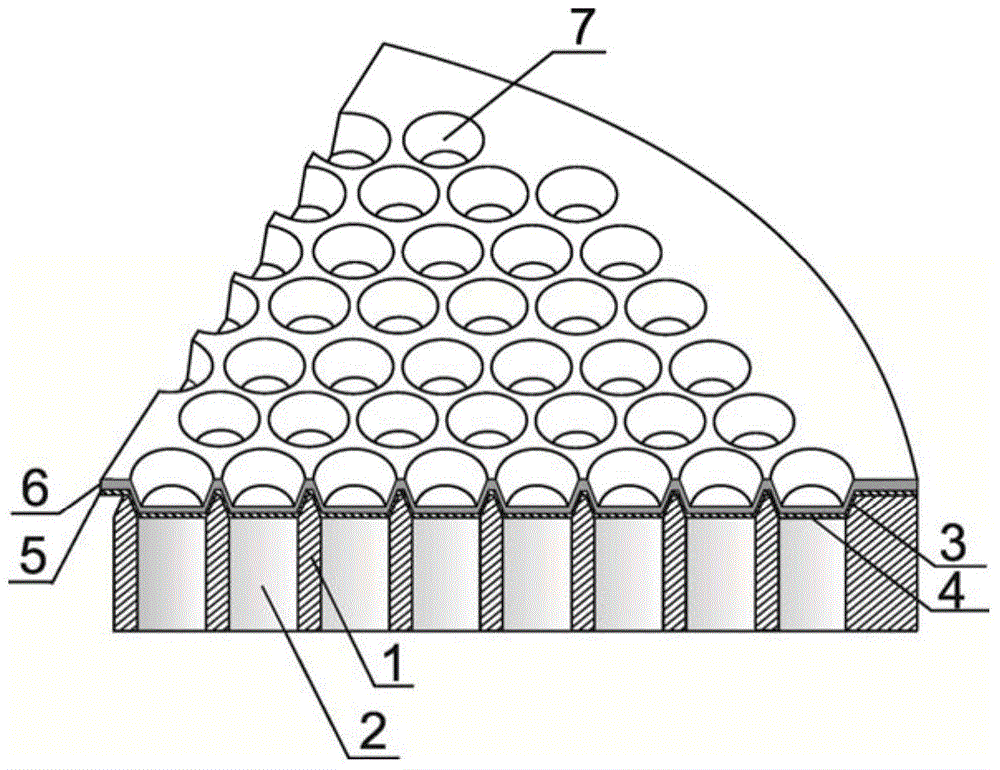

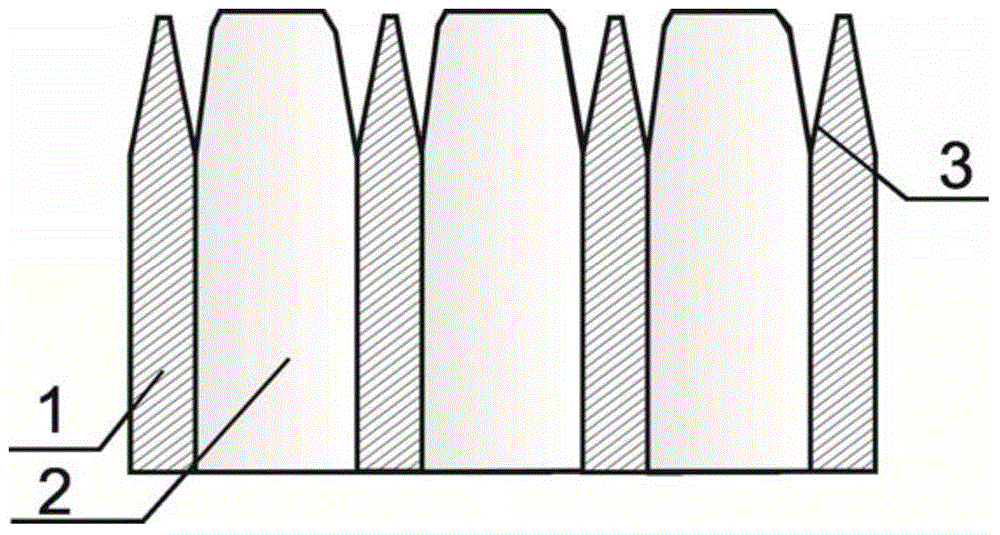

[0028] This embodiment introduces a method for preparing a microstructure-enhanced reflective photocathode for incident light in the X-ray band. see figure 1 , the microstructure-reinforced substrate is made of a microchannel plate composed of skin glass 1 and core glass 2; the microstructure of the microstructure-reinforced substrate is composed of a close-packed array of inverted conical concave microstructures 7; the cone wall 3 is composed of skin glass , The cone bottom 4 is made of core glass; the electrode layer 5 is a Cr metal layer; the photoemission layer 6 is a CsI layer with high photoelectric conversion efficiency for X-rays.

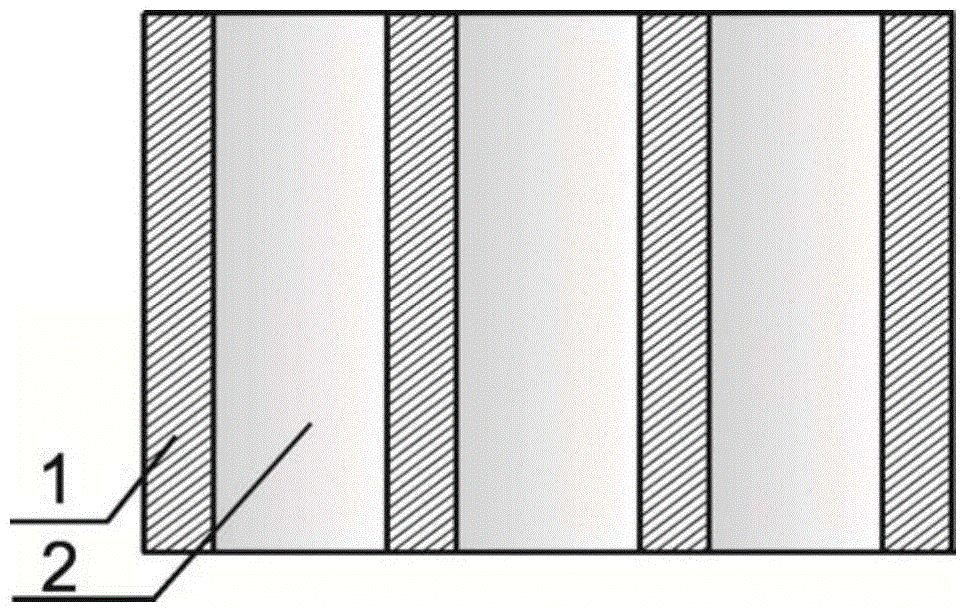

[0029] The step of preparation method of the present invention is, provides a microchannel plate, and this microchannel plate is made of cover glass 1 and core glass 2, as figure 2 shown; the skin glass can be corroded by HF but not by HNO 3 Corroded glass, the core glass is corroded by both HF and HNO 3 Corroded glass.

[0030] After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com