Intelligent power module and intelligent power module manufacturing method

A technology of intelligent power modules and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc. The effect of investment cost, improvement of process qualification rate, and reduction of application difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

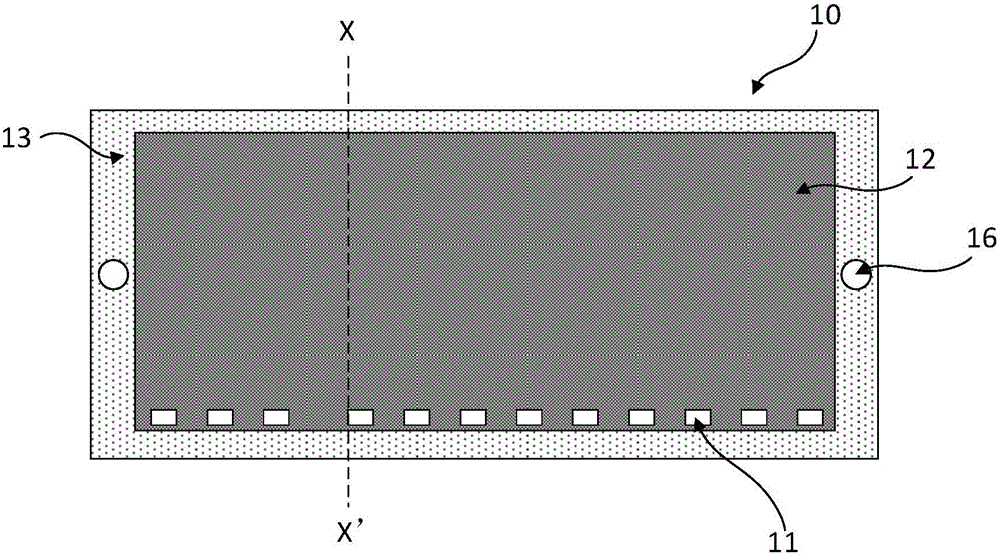

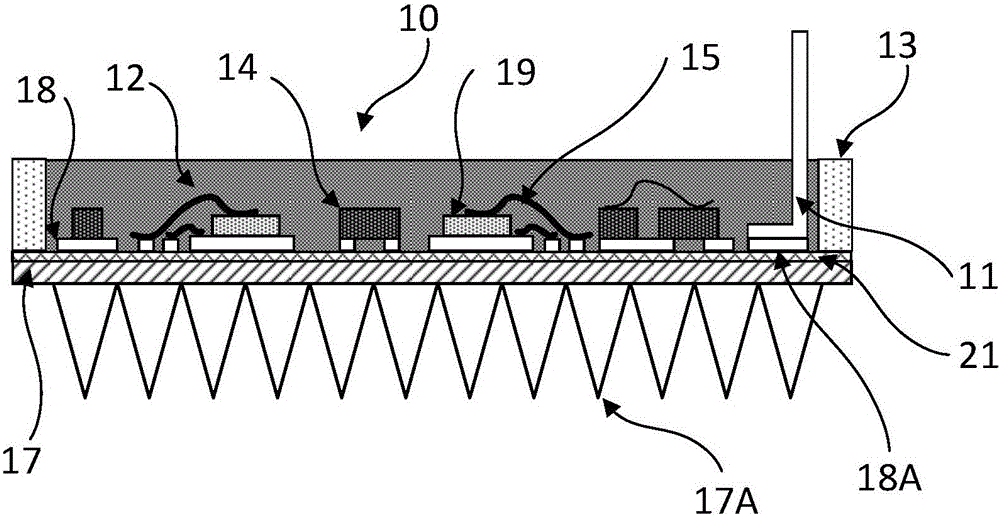

[0038] combine Figure 1(A) and 1(B) , the intelligent power module 10 of the present invention has a pin 11, a sealing layer 12, a metal wire 15, a substrate 17, a circuit wiring (ie, a circuit wiring layer) 18, an insulating layer 21 and circuit components, and the circuit components include power components 19 and non-conductive components. power element 14. The substrate 17 is a paper heat sink, and the substrate 17 includes a first surface and a second surface opposite to the first surface. A large number of heat dissipation folds 17A are formed on the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com