Thin-film structure light-emitting diode (LED) chip based on silver-based metal bonding and preparation method of thin-film structure LED chip

A technology of LED chip and thin film structure, used in semiconductor devices, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In the following, the present invention will be further described by taking a vertically structured LED chip as an example in conjunction with the accompanying drawings.

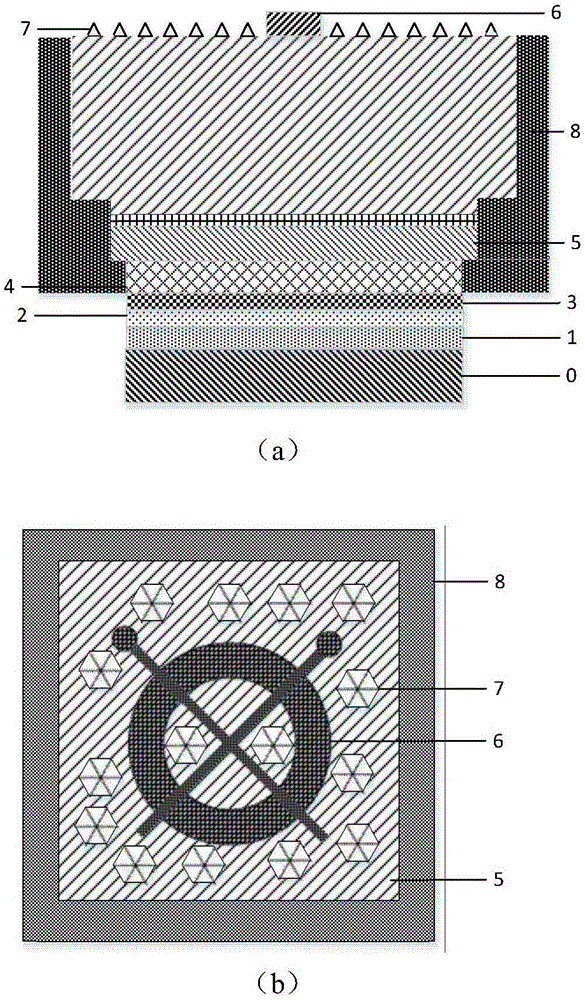

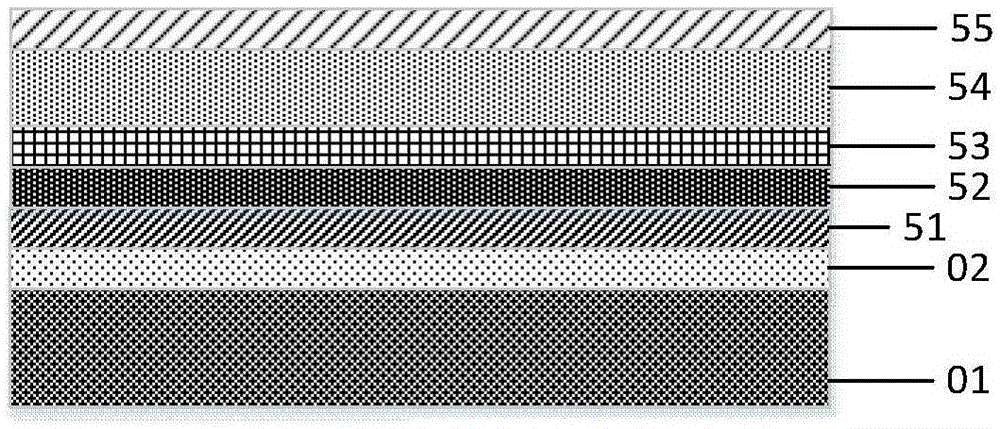

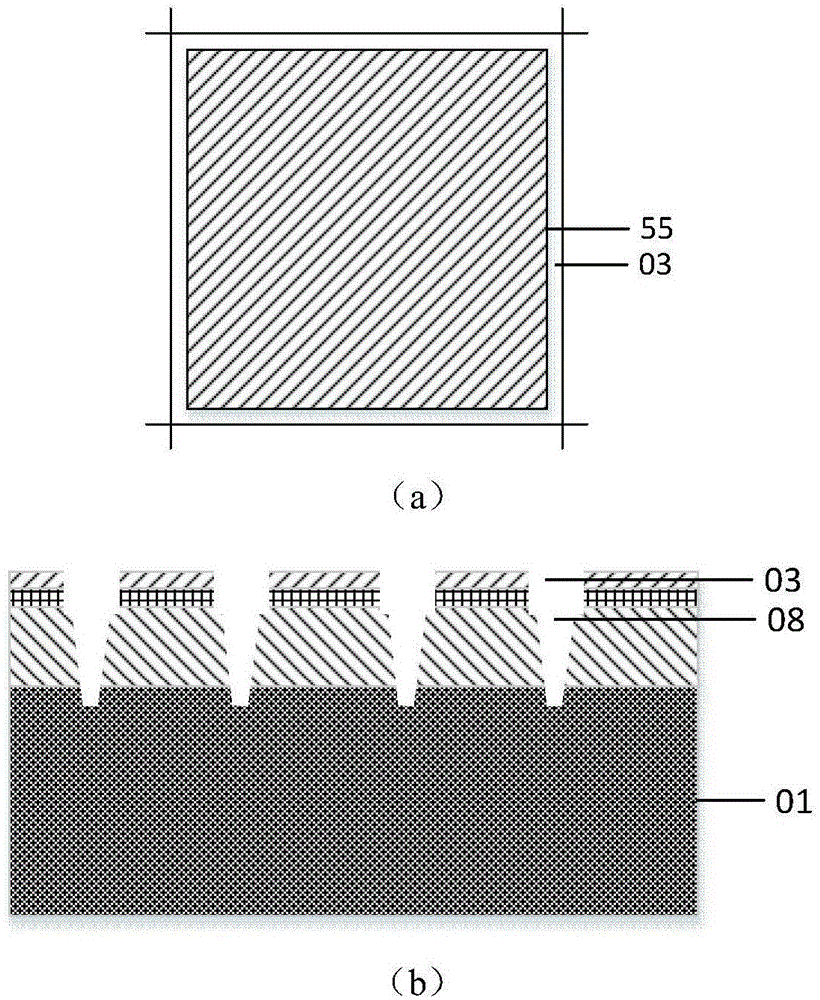

[0070] like figure 1 As shown, the thin-film structure LED chip unit of the vertical structure of this embodiment includes: transfer substrate 0, bonding metal layer 1, transition layer 2, reflective layer 3, p-electrode 4, LED epitaxial layer 5, n-electrode 6, n Surface light cone 7 and passivation layer 8; wherein, on the transfer substrate 0 from bottom to top are bonding metal layer 1, transition layer 2, reflective layer 3, p-electrode 4 and LED epitaxial layer 5; on the LED epitaxial layer N-electrode 6 is formed on a small part of the LED epitaxial layer; n-surface light-emitting cone 7 is formed on the surface of the LED epitaxial layer except for the n-electrode; reflective layer 3 and n-surface light-emitting cone 7 form a light-emitting structure; between LED chip units The sidewalls of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com