Electrolyte for promoting film formation of graphite cathode and battery using electrolyte

A graphite negative electrode and electrolyte technology, applied in secondary batteries, organic electrolytes, non-aqueous electrolytes, etc., can solve the problems of graphite pulverization damage, high melting point, unfavorable low-temperature performance of electrolyte, etc., and achieve low solidification temperature, battery internal small resistance effect

Inactive Publication Date: 2015-11-11

DONGUAN KAIXIN BATTERY MATERIAL

View PDF2 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The electroreduction product of ethylene carbonate on the surface of the graphite negative electrode is relatively stable and is an essential component of the electrolyte solvent system, but the high melting point of ethylene carbonate is not conducive to the low temperature performance of the electrolyte

Propylene carbonate has a wide liquid range, and the dielectric constant and donor number are comparable to ethylene carbonate. It is widely used in primary lithium batteries. However, when propylene carbonate is used with graphite materials, propylene carbonate is easy to intercalate Into the layered structure of graphite, leading to graphite pulverization and destruction

The previous research work in academia hoped that by adding film-forming additives (including vinylene carbonate, fluoroethylene carbonate, dioxalate borate, difluorooxalate borate, vinyl sulfate, etc.) The co-embedding potential of propylene carbonate is formed into a film to inhibit the co-embedding behavior of propylene carbonate. This technical solution controls the destructive effect of propylene carbonate on graphite materials to a certain extent, but the currently developed negative electrode surface formation Membrane additives have limited functionality. In the electrolyte formula combination, propylene carbonate is only suitable for a small amount of addition, and the main component of high dielectric constant solvent can only use ethylene carbonate.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0020] The present invention is further elaborated below by exemplary embodiment; But the scope of the present invention should not be limited to the scope of embodiment, any change or change that does not deviate from the gist of the present invention can be understood by those skilled in the art, all in Within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

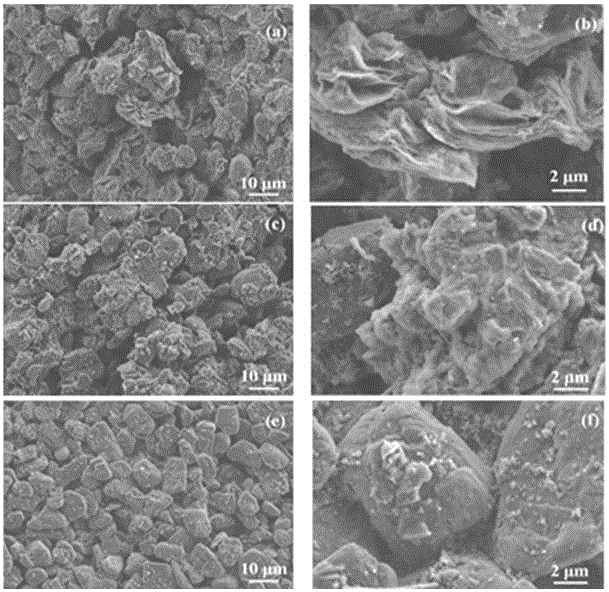

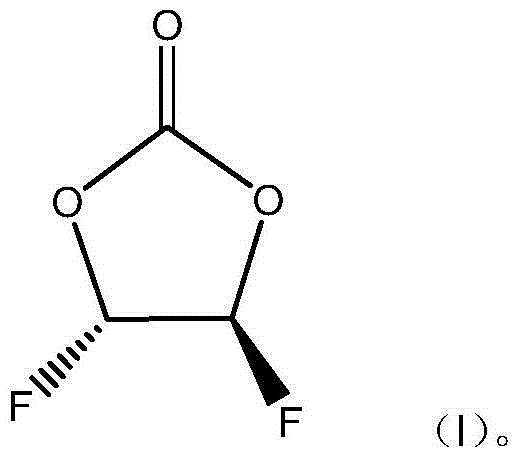

The invention provides electrolyte for promoting film formation of a graphite cathode and a battery using the electrolyte. The electrolyte comprises an electrolyte lithium salt, difluoride ethylene carbonate (DFEC), propylene carbonate (PC) and a non-aqueous organic solvent, wherein a chemical structure of the DFEC is as shown in the formula (I); the formula (I) is as shown in the specification; a lithium secondary battery comprises a positive plate, a negative plate, a diaphragm and the electrolyte for promoting film formation of the graphite cathode provided by the invention. By the DFEC, a passivation film which is stable enough can be formed on the surface of a graphite material; when the PC is utilized by the electrolyte as a high dielectric constant solvent component, graphite powder is not stripped due to the fact that propylene carbonate molecules are embedded into a layered structure of the graphite material, and the lithium ion battery does not lose efficacy in the charging and discharging cycle processes of the lithium ion battery; and the service life of the lithium battery is prolonged.

Description

technical field [0001] The invention relates to the field of lithium ion batteries, in particular to an electrolyte that can promote the film formation of a graphite negative electrode and a battery using the electrolyte. Background technique [0002] Lithium secondary batteries have the advantages of high working voltage, high specific energy density, long cycle life, low self-discharge rate, no memory effect, and low environmental pollution. Ideal power source for power tools. At present, in the technical market, the negative electrode materials are mainly monopolized by graphite negative electrodes. The electrolyte generally adopts a mixed ring and linear carbonate system to take into account properties such as viscosity, solubility, and conductivity, and various functional additives to meet the requirements. Comprehensive performance of lithium-ion batteries. [0003] The electroreduction product of ethylene carbonate on the surface of the graphite negative electrode i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M10/0567H01M10/42H01M10/0525

CPCH01M10/0525H01M10/0567H01M10/4235H01M2300/0025Y02E60/10

Inventor 韩鸿波仰永军罗乾万华平

Owner DONGUAN KAIXIN BATTERY MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com