Buck-Boost type high-power bidirectional DC/DC converter with coupled inductors

A technology of coupling inductors and converters, which is applied in the direction of converting DC power input to DC power output, output power conversion devices, current collectors, etc., to achieve high efficiency, reduce noise, and improve conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

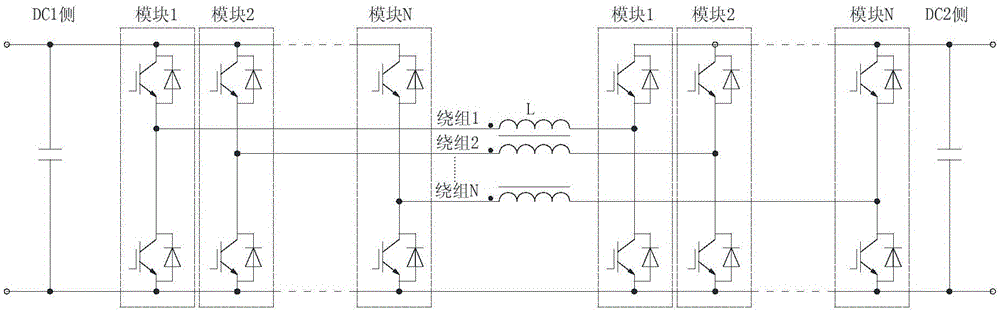

[0029] From image 3 It can be seen that the circuit of the present invention is formed by parallel connection of N-way (N≥2) bidirectional Buck-Boost circuits. The circuit uses N-way coupling inductors, and the circuit structures of the DC1 side and the DC2 side of the two DC sides are completely symmetrical, that is, DC1 The voltage on the DC2 side can be higher or lower than that on the DC2 side. Therefore, the DC converter of the present invention has a wide range of applications (such as electric vehicles, battery energy storage fields). The working process of the circuit of the present invention is briefly analyzed below.

[0030] The circuit topology of the three-phase interleaved Buck-Boost bidirectional DC / DC converter is as follows: Figure 4 shown. The three-phase circuit adopts an interleaved control method, which mainly refers to the operation mode in which the carrier frequency of each phase module is the same, and the phase angles are staggered from each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com