Method for preparing polysaccharide-ADH derivative by means of A-group meningococcal refined sugar

A meningococcal,-ADH technology, applied in the field of preparation of polysaccharide-ADH derivatives, can solve the problems of unfavorable protection of human health and the environment, achieve better derivation effect, ensure human health, and increase the effect of ADH derivation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

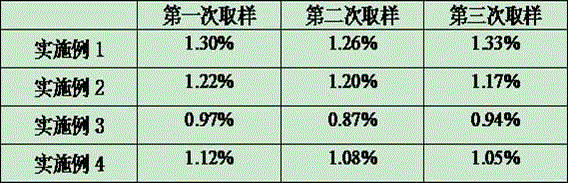

Examples

Embodiment 1

[0025] The method for preparing polysaccharide-ADH derivatives by utilizing group A meningococcal refined sugar comprises the following steps:

[0026] (1) Dissolve meningococcal refined sugar in water for injection to prepare a polysaccharide solution with a concentration of 5 mg / ml, and adjust the pH to 9.0 with sodium hydroxide;

[0027] (2) Dissolve CDAP with acetonitrile to form a CDAP solution with a concentration of 100mg / ml; then add CDAP solution to the polysaccharide solution according to the weight ratio of polysaccharide:CDAP=1:0.5, and stir at room temperature for 2-5 minutes to make a CDAP mixture ;

[0028] (3) Add ADH with 0.2mol / L NaHCO 3 Dissolve into an ADH solution with a concentration of 100mg / ml, add ADH solution to the CDAP mixture according to the weight ratio of polysaccharide: ADH=1:3.5, and stir at room temperature for 1 hour;

[0029] (4) Finally, filter with ultrafiltration membrane bag. The ultrafiltrate used in ultrafiltration membrane bag filt...

Embodiment 2

[0031] The only difference between this example and Example 1 is that the weight ratio of polysaccharide and CDAP in step (2) in this example is 1:0.6; the weight ratio of polysaccharide and ADH in step (3) is 1:4.

Embodiment 3

[0033] The difference between this embodiment and embodiment 1 is only that the proportion and concentration of each chemical substance in this embodiment are added to the reaction, and the specific settings are as follows:

[0034] The concentration of the polysaccharide solution in step (1) is 10 mg / ml, and the pH is adjusted to 9.0 with sodium hydroxide;

[0035] The concentration of CDAP solution in step (2) is 80mg / ml, polysaccharide:CDAP=1:0.7;

[0036] The concentration of ADH solution in step (3) is 80mg / ml ADH solution, polysaccharide: ADH=1:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com