A chemical tail gas deodorization equipment and deodorization method

A technology for chemical exhaust gas and chemical equipment, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of increased processing costs, inconvenient processing, complicated procedures, etc., to reduce sulfur dioxide content and improve purity and quality. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

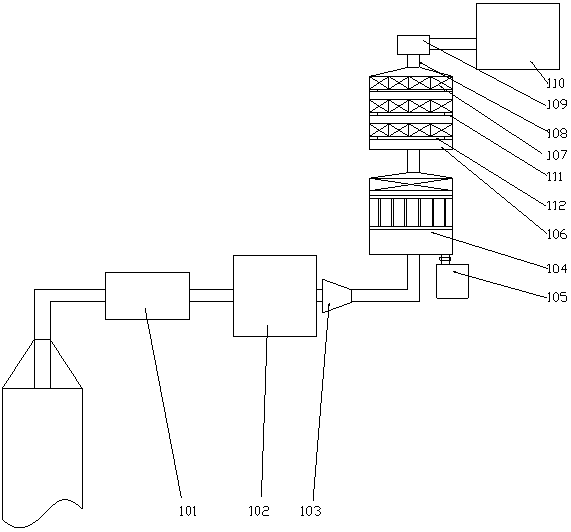

[0025] Such as figure 1 As shown, a chemical tail gas deodorization equipment includes a high-pressure dissolved air pump 101 connected to chemical equipment through pipelines;

[0026] The high-pressure dissolved air pump 101 is connected to the airtight water tank 102 through a pipeline, the output end of the airtight water tank 102 is provided with a jet pump 103, and the output end of the jet pump 103 is connected to the gas-liquid separation chamber 104. A gas-liquid separator is arranged in the gas-liquid separation chamber 104;

[0027] A liquid storage tank 105 is arranged at the lower end of the gas-liquid separation chamber 104, and a one-way valve connected with the desulfurization chamber 106 is arranged at the upper end of the gas-liquid separation chamber 104;

[0028] The desulfurization chamber 106 is provided with an adsorption layer 107, the adsorption layer 107 is a honeycomb structure, the surface of the adsorption layer 107 is provided with a calcified de...

Embodiment 2

[0035] A method for deodorizing chemical tail gas, comprising the following steps:

[0036] S1: Use the high-pressure dissolved air pump 101 to pressurize the chemical tail gas into the closed water tank 102, so that the ammonia and air in the chemical tail gas are pressurized and transported to the closed water tank 102, and a large amount of air squeezes the ammonia dissolved in the water, and the water absorbs it part of sulfur dioxide;

[0037] S2: Start the jet pump 103 to atomize the ammonia dissolved in water and spray it out at a high speed, so that ammonia enters the gas-liquid separation chamber 104 and is separated from water through the gas-liquid separator, and the remaining sulfur dioxide and ammonia enter the desulfurization chamber through the gas-liquid separator 106;

[0038] S3: Start the air pump to generate negative pressure in the desulfurization chamber 106, so that the gas accelerates through the desulfurization chamber 106. After the sulfur dioxide is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com