Integrated device for kitchen waste continuous crushing pulping and component sorting

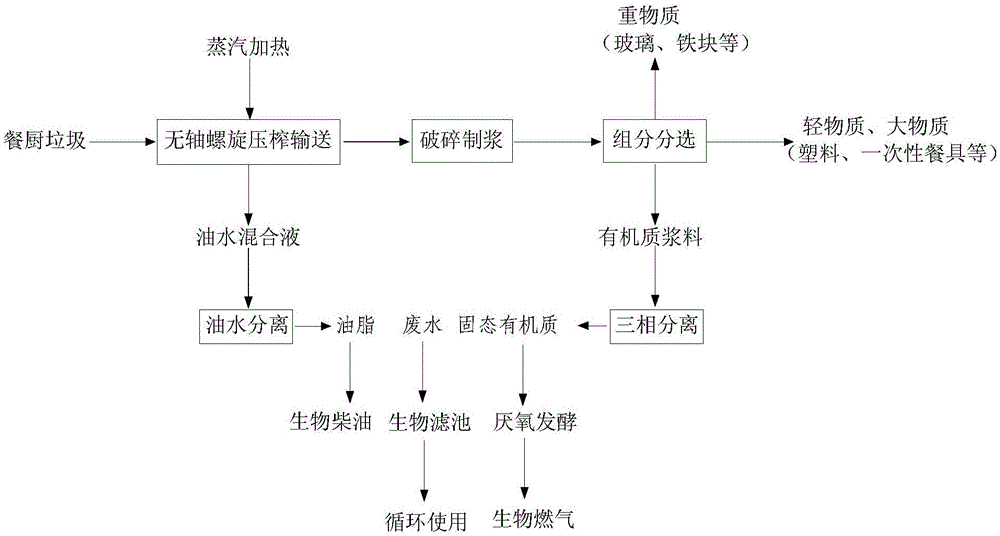

A kitchen waste and integrated device technology, which is applied in the field of integrated devices for continuous crushing and pulping and component sorting of kitchen waste, can solve the problem of difficulty in achieving continuous and efficient operation, easy winding and clogging of equipment, and poor separation of impurities. and other problems, to achieve the effect of efficient crushing and pulping, saving equipment investment and not easy to entangle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

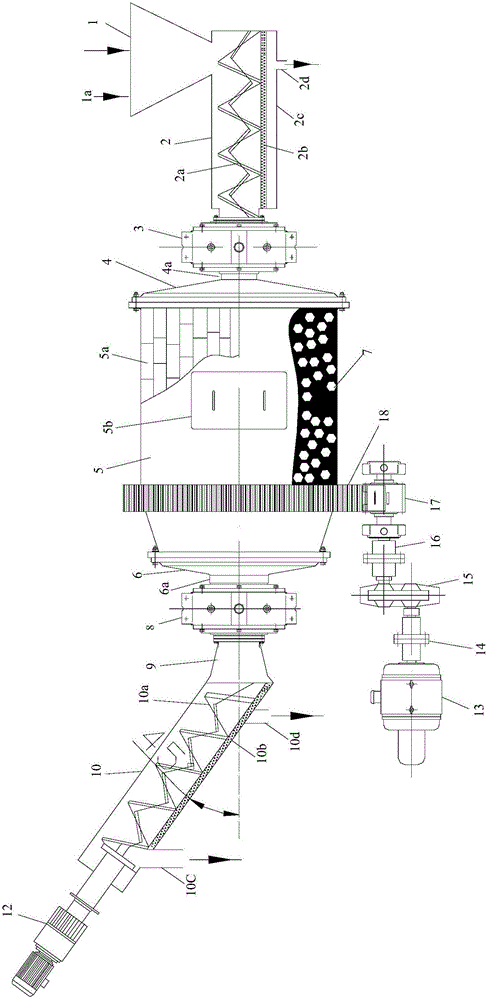

[0030] refer to Figure 1 to Figure 6 , is an integrated device for continuous crushing, pulping and component sorting of food waste, including a main drive device, a feed oil extraction device connected in sequence, a main bearing at the feed end, a crushing chamber, a main bearing at the discharge end, Discharging and sorting device, the main driving device provides the power required for the operation of the crushing chamber;

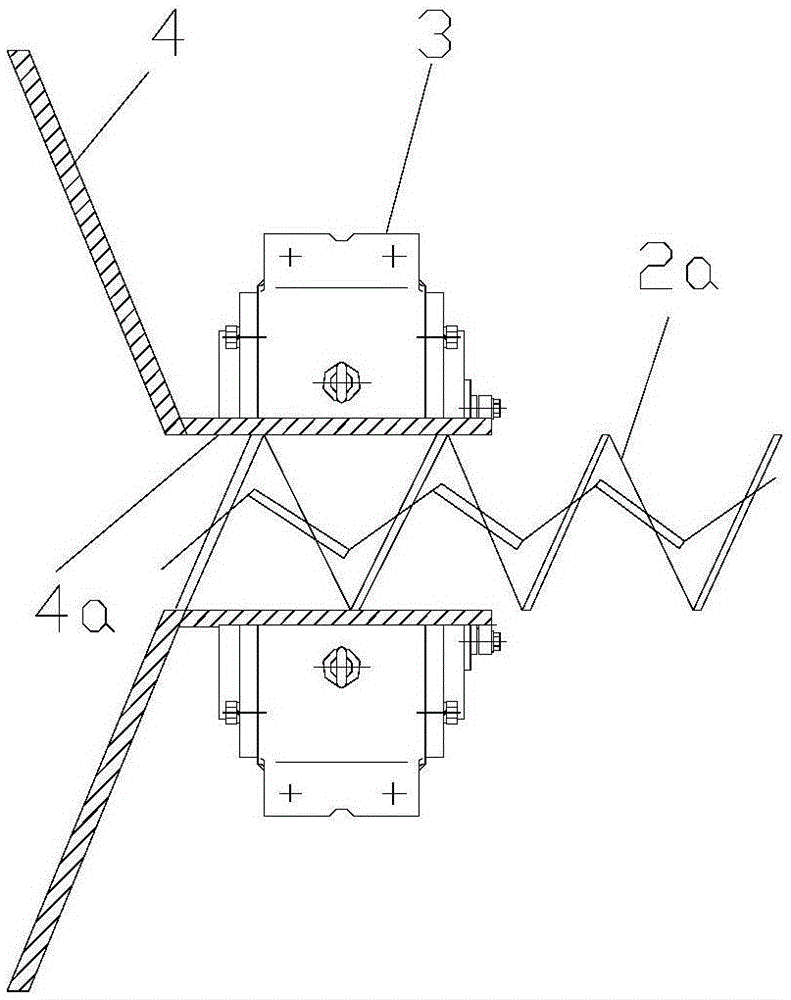

[0031]The feed oil extraction device is composed of the unloading bin 1 located above and the shaftless screw press conveying device I2 installed horizontally in the middle; the upper part of the unloading bin 1 is equipped with an automatic lifting cover plate and superheated steam inlet 1a; the shaftless screw press conveying device I2 consists of a shaftless spiral blade I2a installed horizontally from top to bottom, an oil-water filter 2b and an oil-water collection bin 2c, and an oil-water outlet 2d is opened below the oil-water collection bin 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com