High-specific-area white carbon black and production method thereof

A technology of high specific surface area and silica, applied in the direction of silica, inorganic chemistry, non-metallic elements, etc., can solve the problems of low specific surface area of silica, environmental pollution, difficulty in meeting high specification requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

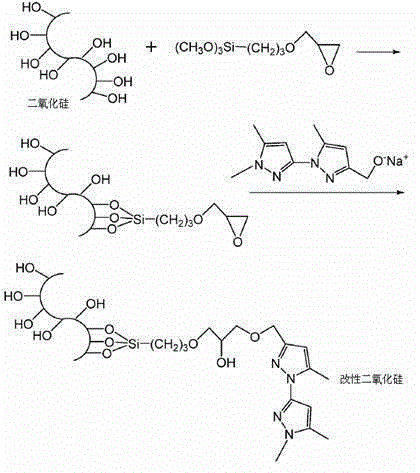

Method used

Image

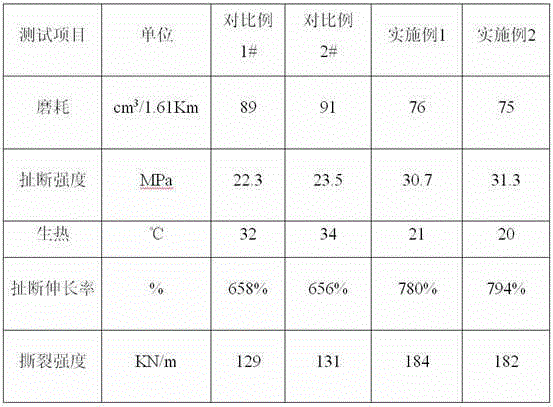

Examples

Embodiment 1

[0059] SiO 2 / Na 2 The weight ratio of O is 3.35, and liquid sodium silicate and water with a concentration of 1.30mol / l are added to the reaction kettle. The total amount of water and dilute liquid sodium silicate accounts for 44% of the final reaction, and 10% sulfuric acid is added dropwise until the pH is 8.8.

[0060]Add the dilute liquid sodium silicate and sulfuric acid into the synthesis reaction kettle at a certain rate at the same time according to the weight ratio of 0.9:1, and at the same time pass steam into the heating pressure greater than 0.3Mpa, react at a temperature of 75°C for 65min, and maintain the pH of the reaction material 8.5

[0061] Then add sulfuric acid dropwise to adjust the pH to 5.0 and finish the reaction to obtain dilute silica slurry;

[0062] The obtained dilute silica slurry is filtered through a filter press, fed under a pressure of 0.45Mpa for 13 minutes, and then washed under a pressure of 0.65Mpa until the conductivity of the washin...

Embodiment 2

[0074] SiO 2 / Na 2 The weight ratio of O is 3.30, and liquid sodium silicate and water with a concentration of 1.25mol / l are added to the reaction kettle. The total amount of water and dilute liquid sodium silicate accounts for 48% of the final reaction, and 10% sulfuric acid is added dropwise until the pH is 9.0.

[0075] Add the dilute liquid sodium silicate and sulfuric acid into the synthesis reaction kettle at a certain rate at the same time according to the weight ratio of 1.1:1, and at the same time pass through steam to heat the pressure greater than 0.3Mpa, react at a temperature of 80°C for 60min, and maintain the pH of the reaction material 8.4

[0076] Then add sulfuric acid dropwise to adjust the pH to 5.2 and finish the reaction to obtain dilute silica slurry;

[0077] The obtained dilute silica slurry is filtered through a filter press, fed under a pressure of 0.40Mpa for 10 minutes, and then washed under a pressure of 0.56Mpa until the conductivity of the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com