Method for producing food-grade potassium chloride by adopting adsorption process

A potassium chloride, food-grade technology, applied in the field of production of food-grade potassium chloride, can solve the problem of not being able to meet the requirements of food-grade potassium chloride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

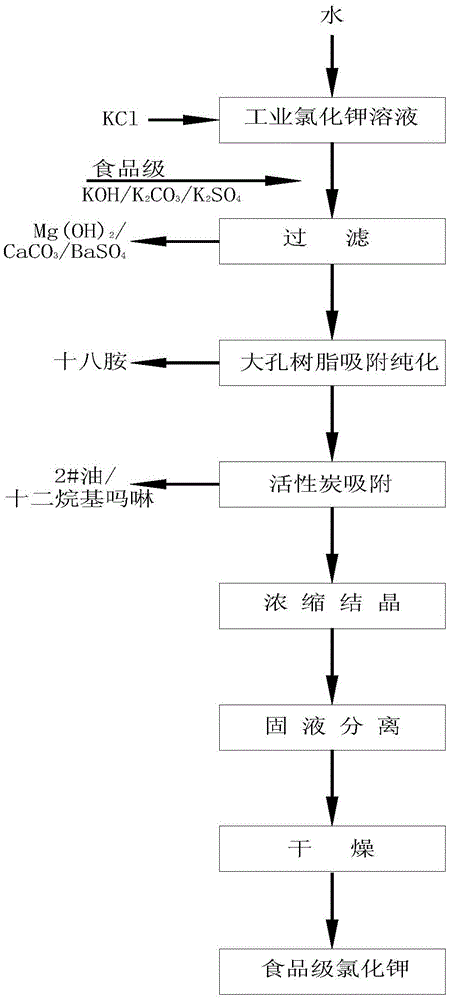

[0018] Such as figure 1 Shown, a kind of method that adopts adsorption technology to produce food-grade potassium chloride, specifically divides the following steps to implement:

[0019] a) dissolving: at room temperature, dissolve the industrial grade potassium chloride solid into a potassium chloride solution;

[0020] b) Filtration: Add one or several mixtures of food-grade potassium hydroxide or potassium carbonate or potassium sulfate to the potassium chloride solution to allow it to mix with a small amount of calcium ions, magnesium ions or barium ions in industrial potassium chloride, etc. Impurities are reacted, and precipitates such as calcium carbonate, magnesium sulfate or barium sulfate are obtained after the reaction; the crude potassium chloride solution containing the precipitate is filtered through a filter, and the precipitate is filtered out to obtain the potassium chloride primary solution I;

[0021] c) Multistage macroporous resin adsorption purification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com