Preparation method of high-yield and low-cost peptizer DBD

A peptizer and low-cost technology, which is applied in the field of preparation of high-yield and low-cost peptizer DBD, can solve the problem of low product yield and quality, complex production process synthesis path, production process synthetic raw materials and high engineering process costs. problem, to achieve the effect of stable product quality, shortening crystallization time, and simple and convenient path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

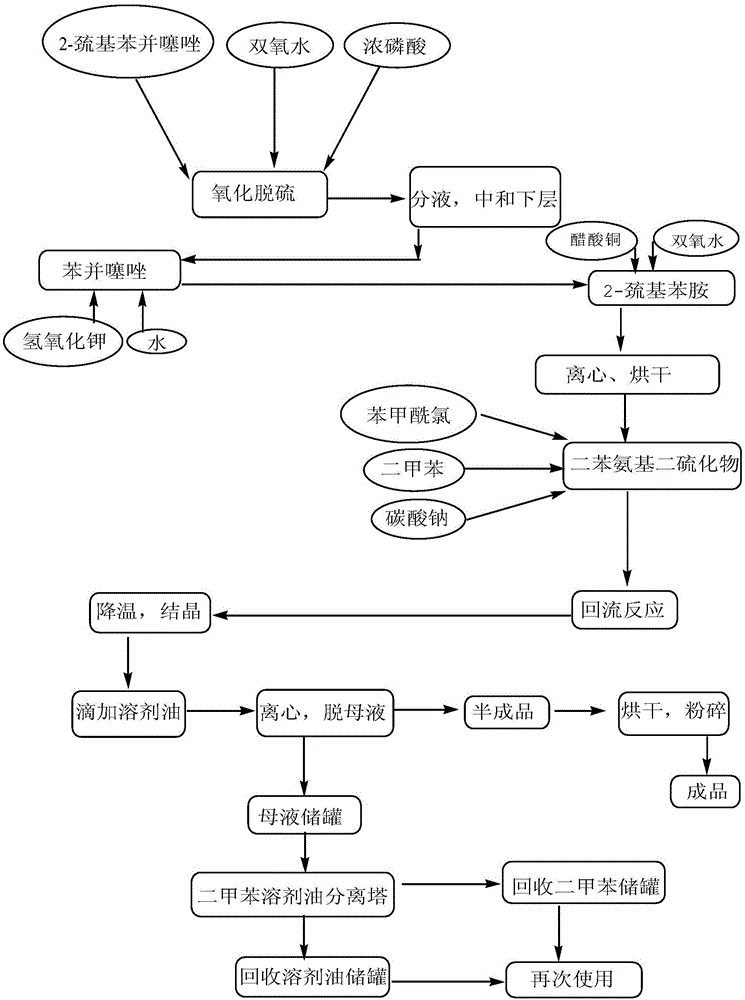

Image

Examples

Embodiment 1

[0046] A kind of preparation method of peptizer DBD with high yield and low cost comprises steps as follows:

[0047] (1) Get 100g of 2-mercaptobenzothiazole and mix it with 250g of 30wt% hydrogen peroxide, add 400g of water to dilute, heat up at 20°C to oxidize mercapto, react for 2 hours, then add 50g of concentrated phosphoric acid of 85wt% to acidify for 2.5 hours, remove Remove the oxidized mercapto groups, separate the liquid after standing for stratification, remove the upper liquid, and then use soda ash to adjust the pH of the lower liquid to 7 to obtain liquid benzothiazole,

[0048](2) 50 g of liquid benzothiazole is mixed with 100 g of a saturated solution of potassium hydroxide with a concentration of 40 wt %, heated up to 125° C. for 5 h to react with alkali decarburization, and after the reaction is finished, add water to cool down to obtain 2-mercaptoaniline. The amount of water added is the same as that of the liquid The mass ratio of benzothiazole is 5:2,

...

Embodiment 2

[0053] A kind of preparation method of peptizer DBD with high yield and low cost comprises steps as follows:

[0054] (1) Get 150g of 2-mercaptobenzothiazole and mix it with 375g of 40wt% hydrogen peroxide, add 600g of water to dilute, heat up at 20°C to oxidize mercapto, react for 2 hours, then add 70g of concentrated phosphoric acid of 85wt% to acidify for 2.5 hours, remove Remove the oxidized mercapto groups, separate the liquid after standing for stratification, remove the upper liquid, and then use soda ash to adjust the pH of the lower liquid to 7 to obtain liquid benzothiazole,

[0055] (2) 100g of liquid benzothiazole is mixed with 100g of saturated potassium hydroxide solution with a concentration of 40wt%, and the temperature is raised to 125° C. for 5 hours to react with alkali decarburization. After the reaction, water is added to cool down to obtain 2-mercaptoaniline. The amount of water added is the same as that of the liquid The mass ratio of benzothiazole is 5:...

Embodiment 3

[0060] A kind of preparation method of peptizer DBD with high yield and low cost comprises steps as follows:

[0061] (1) Get 55g of 2-mercaptobenzothiazole and mix it with 120g of 40wt% hydrogen peroxide, add 200g of water to dilute, heat up at 20°C to oxidize mercapto, react for 2 hours, then add 25g of concentrated phosphoric acid of 86wt% to acidify for 2.5 hours, remove Remove the oxidized mercapto groups, separate the liquid after standing for stratification, remove the upper liquid, and then use soda ash to adjust the pH of the lower liquid to 7 to obtain liquid benzothiazole,

[0062] (2) 40 g of liquid benzothiazole is mixed with 110 g of a saturated solution of potassium hydroxide with a concentration of 40 wt%, and the temperature is raised to 125° C. for 5 hours to react with alkali decarburization. After the reaction, water is added to cool down to obtain 2-mercaptoaniline. The amount of water added is the same as that of the liquid The mass ratio of benzothiazole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com