Modified heat-resistant plastic

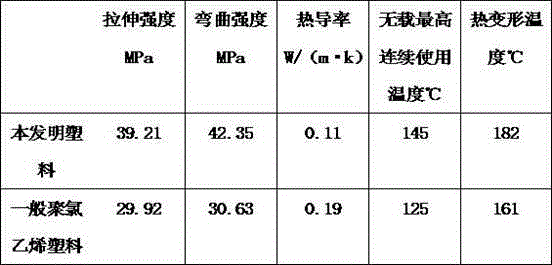

A modified and heat-resistant technology, which is applied in the field of modified heat-resistant plastics, can solve the problems of physical and mechanical properties degradation, poor stability, and small branching degree, and achieve improved heat resistance, low cost, and enhanced anti-friction and wear resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A modified heat-resistant plastic, the modified heat-resistant plastic is made of the following components in parts by weight: 45 parts of polyvinyl chloride resin, 32 parts of acrylic resin, 10 parts of aluminum powder, 6 parts of modified glass fiber, hard 1 part of calcium fatty acid, 3 parts of dispersant, 2 parts of heat stabilizer, 1 part of plasticizer.

[0012] Further, the aluminum powder is calcined aerobically at 200°C.

[0013] Further, the dispersant is sodium hexametaphosphate.

[0014] Further, the heat stabilizer is lead dibasic phosphite.

[0015] Further, the plasticizer is citrate.

[0016] Further, the manufacturing method of the modified glass fiber is as follows: soak the glass fiber in 0.5-1% concentration of silane coupling agent for 2-3 hours at 65-70°C, add sodium carboxymethyl cellulose, heat To 85-90°C for 1-1.5 hours, filter and dry.

[0017] A method for making a modified heat-resistant plastic, comprising:

[0018] 1) Weigh by weight,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com