A kind of high temperature lubricating oil for dc casting of aluminum alloy

A technology for lubricating oil and aluminum alloy, applied in the field of aluminum alloy casting, can solve the problems of destroying the use effect of lubricating oil, lubricating oil evaporation, carbon deposition and coking, etc., to achieve excellent high temperature stability, prolong life, and eliminate cleaning problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

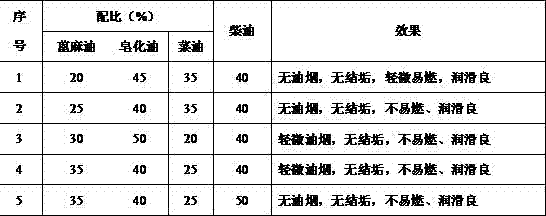

[0022] According to experiments, castor oil, saponified oil, and crude rapeseed oil are calculated according to five groups of weight proportions, and after refining and melting, the resulting mixed oil has lubricating effect. As shown in the following table:

[0023]

[0024] It is refined according to five groups of ratios. It needs to be used according to the ambient temperature. When adding diesel oil to high-temperature lubricating oil for dilution in summer, the lower limit of diesel oil should be used: the weight ratio of high-temperature lubricating oil to diesel oil is 1: 0.3 Dilution, take the upper limit in winter: the weight ratio of high-temperature lubricating oil and diesel oil is 1: 0.5 for dilution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com