Image sensor chip packaging method

A sensor chip and packaging method technology, which is applied in the direction of radiation control devices, electrical components, electric solid devices, etc., can solve the problems of increasing the thickness of the packaging body and complicated manufacturing process, and achieve the advantages of reduced packaging process, simple packaging process and good protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for packaging an image sensing chip, performed in the following steps:

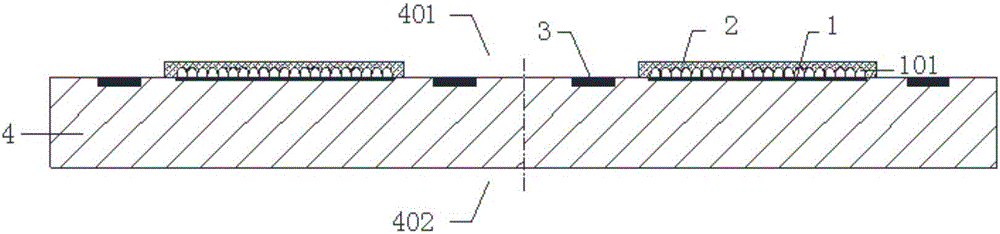

[0043] a. see Figure 1a , provide a wafer 4 with some image sensing chips, the front side 401 of the wafer is the functional surface of the image sensing chip, the back side 402 of the wafer is the lower surface of the base of the image sensing chip, the function of each image sensing chip The surface has a photosensitive area 1 and several welding pads 3 located around the photosensitive area, and the photosensitive area is coated with a dielectric film 2 with insulation, high light transmission, resistance to wiping and erosion of liquid medicine; There is a cutting line between the image sensor chips for cutting and separating into single chip units. The center position of the cutting line is as follows: Figure 1a Shown by the dotted line.

[0044] In this embodiment, the dielectric film is a cube structure parallel to the wafer surface, such as Figure 1a shown. In other embodiments...

Embodiment 2

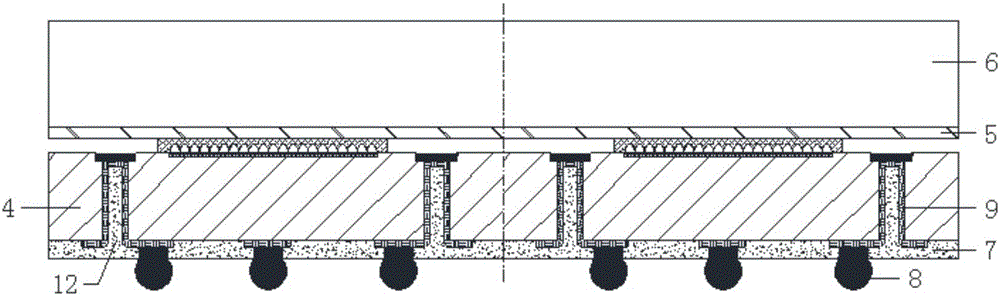

[0057]A method for packaging an image sensing chip, performed in the following steps:

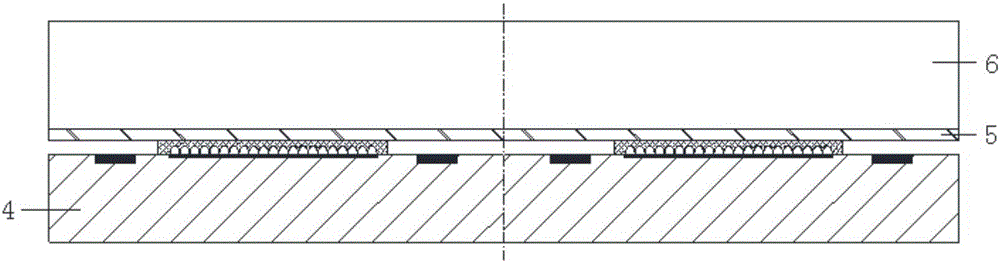

[0058] a. see Figure 2a , provide a wafer 4 with some image sensing chips, the front side 401 of the wafer is the functional surface of the image sensing chip, the back side 402 of the wafer is the lower surface of the base of the image sensing chip, the function of each image sensing chip The surface has a photosensitive area 1 and several welding pads 3 located around the photosensitive area, and the photosensitive area is covered with a dielectric film 2 with insulation, high light transmission, resistance to wiping and corrosion by liquid medicine; There are dicing lines between the image sensor chips; and the welding pads on the front of the chip are partially exposed, and metal bumps 13 are plated on the welding pads on the front of the chip;

[0059] b. providing a carrier 6 having a first surface and a second surface opposite thereto;

[0060] c. see Figure 2b , setting a bondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com