Resin black matrix substrate and touch panel

A resin and black matrix technology, which is applied in optics, instruments, electrical digital data processing, etc., can solve the problem of high surface reflectivity of resin black matrix, and achieve the effect of high shading, low reflectivity, and thin film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

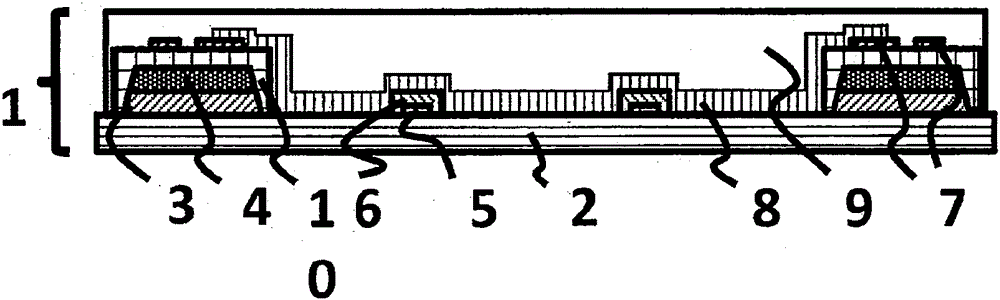

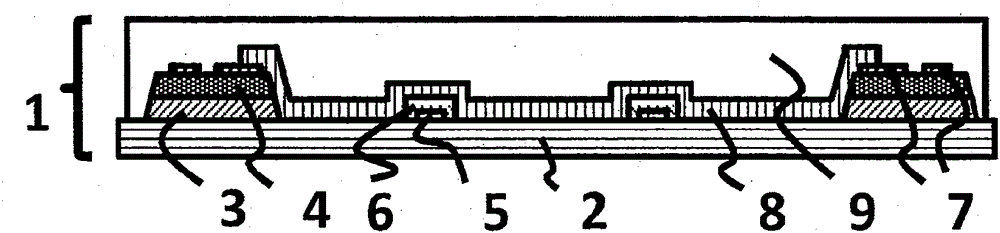

Image

Examples

Embodiment 1

[0159] After filtering the produced photosensitive colored resin composition A-1 with a filter made of Teflon (registered trademark) of 2 μm, a filter made by Mikasa Co., Ltd. was used so that the film thickness was 1.5 μm (after post-baking). Coating device 1H-DS Coats on a chemically strengthened glass substrate with a thickness of 0.7 μm. The substrate coated with the photosensitive colored resin composition A-1 was heat-treated for 2 minutes using needle-shaped protrusions on a hot plate at 90° C., and then the substrate was directly placed on the hot plate for 2 minutes for pre-baking. Using a mask aligner (PEM-6M, produced by Union Optical Co., Ltd.) for this coating film, the mask was used for the resolution test at 200 mJ / cm through the mask for the resolution test. 2 Exposure at the exposure level.

[0160] Next, it developed with the alkali developer of 0.045 mass % potassium hydroxide aqueous solution, and wash|cleaned with pure water next, and the board|substrate ...

Embodiment 2

[0163] Except having used A-2 as a photosensitive colored resin composition, it carried out similarly to BM (A)-1, and obtained the BM (A)-2 board|substrate.

[0164] Except for using B-1 as the photosensitive colored resin composition, BM(B)-1 was formed on the BM(A)-2 substrate with a film thickness of 1.4 μm in the same manner as BM(A)-1, Make two layers of BM-2.

Embodiment 3

[0166] A BM(A)-3 substrate was obtained in the same manner as BM-1 except that A-2 was used as the photosensitive colored resin composition so that the film thickness was 1.0 μm.

[0167] Except for using B-1 as the photosensitive colored resin composition, BM(B)-1 was formed on the BM(A)-3 substrate with a film thickness of 1.4 μm in the same manner as BM(A)-1, Make two layers of BM-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com