Manufacturing method of glass substrate for magnetic disk, glass substrate for magnetic disk, and manufacturing method of magnetic disk

A technology for glass substrates and manufacturing methods, which is applied in the manufacture of base layers, disc carrier manufacturing, magnetic recording layers, etc., which can solve the problems of increased proportion of glass substrates, narrow intervals, etc., and achieve the effect of reducing foreign matter defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

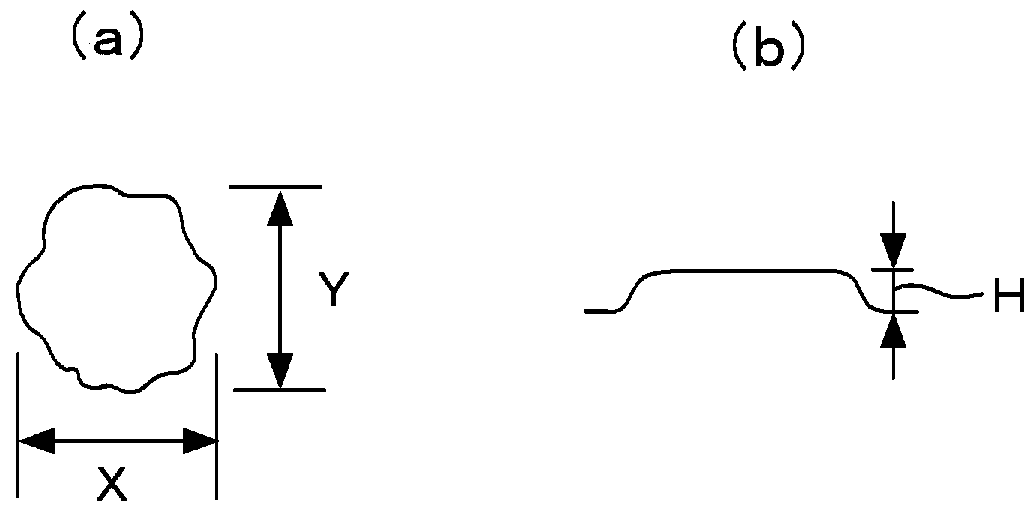

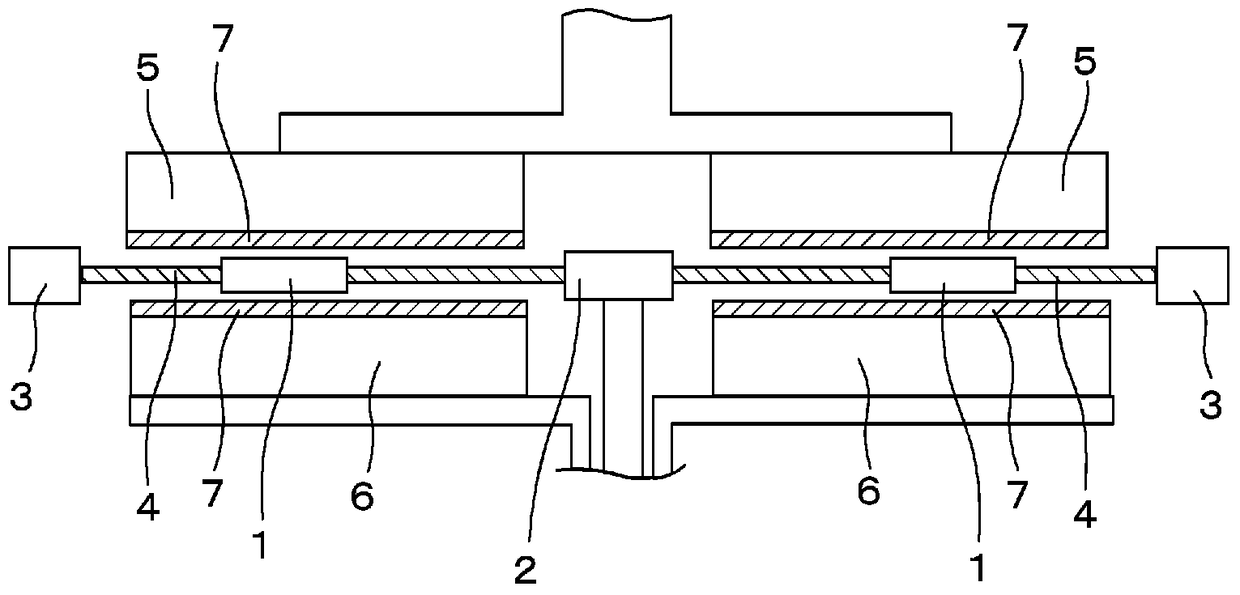

[0134] After the following (1) rough grinding process (rough grinding process), (2) shape processing process, (3) finish grinding process (finish grinding process), (4) end surface grinding process, (5) main surface Polishing process (1st grinding|polishing process), (6) chemical strengthening process, (7) main surface grinding|polishing process (2nd grinding|polishing process), the glass substrate for magnetic discs of this Example was manufactured.

[0135] (1) Rough polishing process

[0136] First, a diameter of , A disc-shaped glass substrate made of aluminosilicate glass with a thickness of 1.0 mm. Moreover, in addition to obtaining a glass substrate by such direct press, it is also possible to obtain a glass substrate by cutting sheet glass produced by a down-draw method or a float method into a predetermined size.

[0137] Next, the glass substrate is subjected to a polishing process to improve dimensional accuracy and shape accuracy. This polishing step is perform...

Embodiment 2

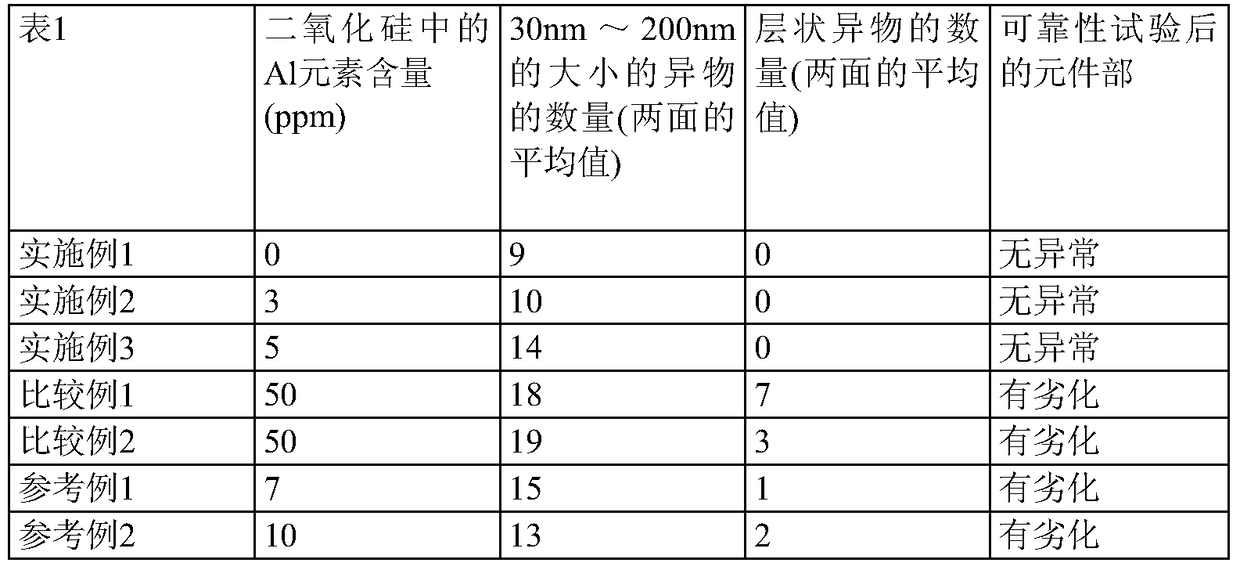

[0155] As said colloidal silica, except having used what content of Al was 3 microgram / g, it carried out similarly to Example 1, and obtained the glass substrate for magnetic discs. In addition, the Al content is the content of Al contained in the solid substance obtained by evaporating and drying the colloidal silica slurry.

Embodiment 3

[0157] As said colloidal silica, except having used what content of Al was 5 microgram / g, it carried out similarly to Example 1, and obtained the glass substrate for magnetic discs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com