An edible fungus liquid spawn fermentation tank and application thereof

A technology of liquid strains and edible fungi, which is applied in the fields of application, horticulture, botany equipment and methods, etc., can solve problems such as pollution and the flow of contaminated strains into production, so as to avoid secondary pollution, meet the growth and reproduction needs of miscellaneous bacteria, The effect of the simple and fast sampling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

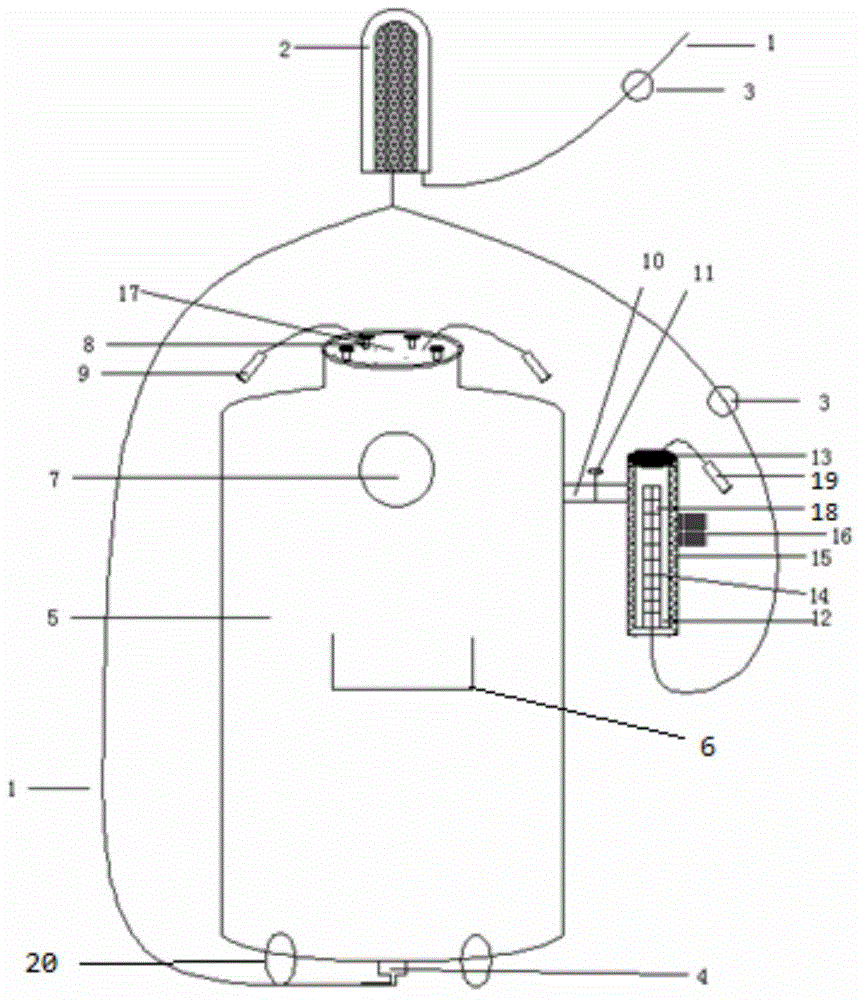

[0039] Below in conjunction with accompanying drawing, illustrate edible fungus liquid strain fermenter of the present invention.

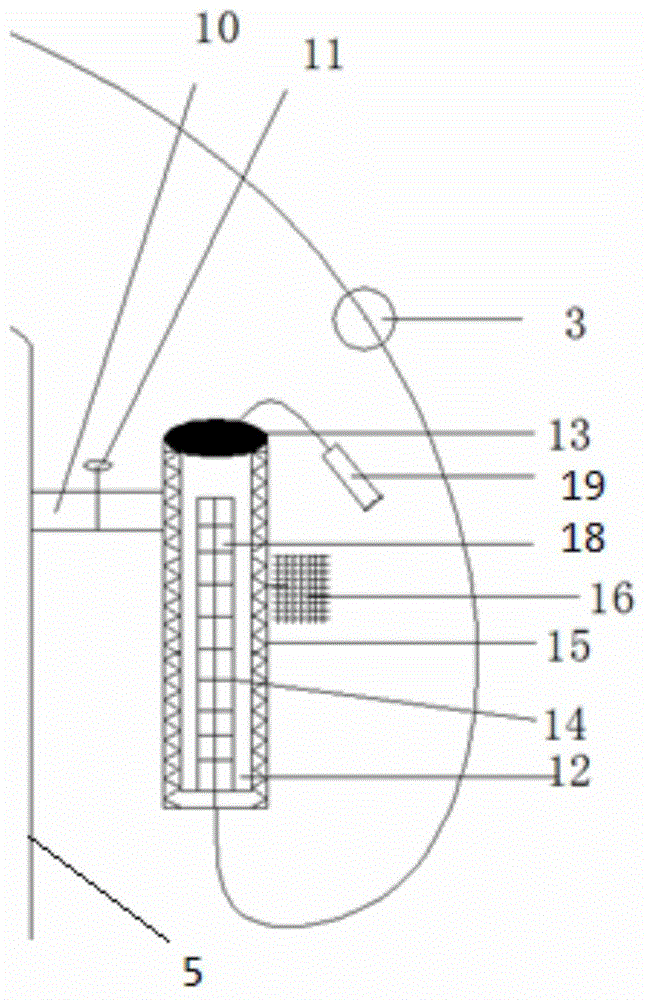

[0040] Edible fungus liquid spawn fermenter is made of air filtration system, main tank 5, auxiliary tank 12 and sampling pipeline 10.

[0041] Wherein, the air filtration system is composed of an air intake pipe 1, a bacterial filter 2 and a quick connector 4, wherein the air intake pipe 1 is connected with a pressure gauge 3;

[0042] The main tank 5 is a fermenter commonly used for edible mushroom liquid strains, and its whole is made of stainless steel with a thickness of 1cm. There are tank lids 17 and exhaust ports 9 on the top of the tank, handles 6 and main tank windows 7 are arranged on the tank body, and the tank lids are tightly closed. Fixed screw 8 is sealed and fixed on the top of the main tank. There are four wheels 20 at the bottom, which are used for fixing and moving the fermenter.

[0043] The auxiliary tank 12 is made of stai...

Embodiment 2

[0046] Take the industrialized production of crab-flavored mushroom liquid strain production process as an example.

[0047] Adopt the fermentor of embodiment 1, the prepared fermenter is carried out the substratum preparation, wherein the substratum in the main tank is prepared according to the routine formula of the industrial production liquid bacterial classification of crab-flavored mushroom, the test substratum in the sub-tank is : Mix 0.35% of soybean meal powder and corn flour through a 120 mesh sieve (mixed according to 1:1 weight ratio), 0.25% of glucose, 0.3% of yeast extract powder, 0.6% of peptone, 0.6% of sodium chloride, 0.4% of 1% phenol red solution %, distilled water 1000mL, pH6.8-7.2. Close the switch valve 11 of the sampling pipeline 10, prepare 100ml test medium, and inject it into the auxiliary tank 12 of the test fermenter. After the main tank 5 and the auxiliary tank 12 are sealed, they enter the autoclave with the help of the wheels 20 at the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com