Production technology for precoated sand recycling

A production process and technology of coated sand, which is applied in the direction of manufacturing tools, metal processing equipment, casting molding equipment, etc., can solve the problems of sand agglomeration, affecting the effect of roasting and coating effect, etc., to avoid sand agglomeration and strengthen the market Value, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

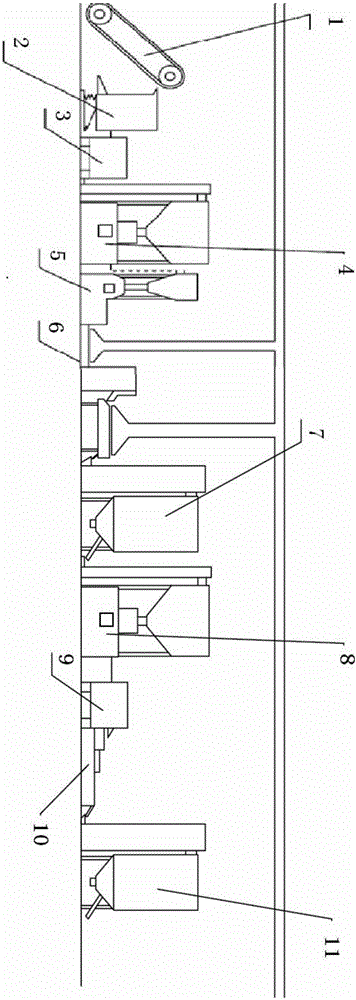

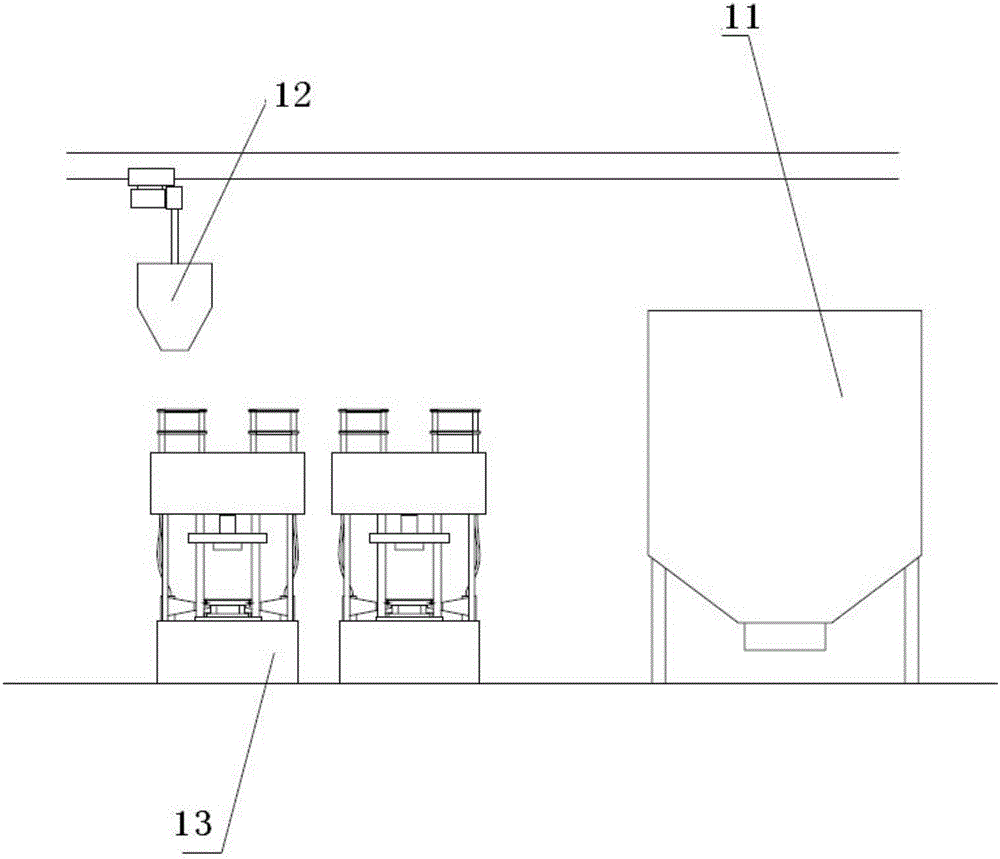

[0027] Reference Figure 1 to Figure 2 The embodiment of the production process of recycled coated sand of the present invention will be further described.

[0028] A production process for the recycling of coated sand, replacing the black sand originally used in the production of sandboxes with coated sand. The coated sand is the molding sand whose surface is covered with a solid resin film. The coated sand has good dispersibility, The shell type does not have a layer, has good thermal stability, good fluidity, and the surface of the processed casting is smooth. Moreover, its high temperature resistance and good release properties make it very suitable for the production of sand boxes.

[0029] Its recycling needs to go through the following steps:

[0030] Step 1: Inject the coated sand into a sand box through a core shooter. The core shooter uses compressed air to evenly inject the molding sand into the pre-mold of the sand box for compaction. The dimensional accuracy of the san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com