Method for preparing graded pressurization liquid forging aluminum alloy engine cylinder cover

An engine cylinder head and liquid die forging technology, which is applied in the field of aluminum alloy for automobiles, can solve the problems of cracks, uneven structure, material waste and other problems in cast aluminum alloy cylinder head, and achieve the elimination of casting defects, uniform structure and improved quality The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

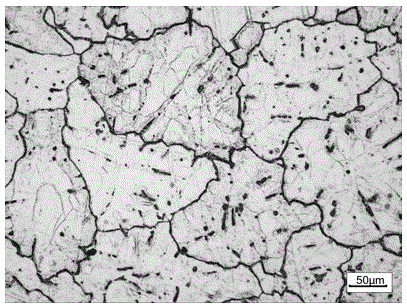

Image

Examples

Embodiment 1

[0018] The preparation method of the staged pressurized liquid die forging aluminum alloy engine cylinder head of this embodiment is carried out according to the following steps:

[0019] (1) Install the upper and lower molds of the engine cylinder head on the die forging machine, preheat the lower mold to 300°C, preheat the upper mold to 280°C, and brush the release agent inside the upper and lower molds;

[0020] (2) Heat the 6063 aluminum alloy to 750°C to melt, and keep it for 1 hour for refining;

[0021] (3) Pour the molten aluminum alloy into the lower mold, and pressurize for the first time when the temperature of the aluminum alloy liquid drops to 690°C. The pressurized pressure is 2000t, and pressurize until the aluminum alloy liquid is still 1mm short of filling the mold cavity Stop, pressurization time is 5 seconds;

[0022] (4) When the temperature of the aluminum alloy liquid drops to 650°C, carry out secondary pressurization, and the aluminum alloy liquid fills...

Embodiment 2

[0025] (1) Install the upper and lower molds of the engine cylinder head on the die forging machine, preheat the lower mold to 320°C, preheat the upper mold to 260°C, and brush the release agent inside the upper and lower molds;

[0026] (2) Heat the 6063 aluminum alloy to 740°C to melt and keep it warm for 1 hour for refining;

[0027] (3) Pour the molten aluminum alloy into the lower mold, and pressurize for the first time when the temperature of the aluminum alloy liquid drops to 680°C. The pressurized pressure is 2000t, and pressurize until the aluminum alloy liquid is less than 1mm full of the mold cavity. Stop, pressurization time is 5 seconds;

[0028] (4) When the temperature of the aluminum alloy liquid drops to 585°C, carry out secondary pressurization, and the aluminum alloy liquid fills the mold cavity and maintains the pressure for 20 seconds;

[0029] (5) After the pressure holding is completed, the pressure is removed, and the cylinder head is taken out for wat...

Embodiment 3

[0031] (1) Install the upper and lower molds of the engine cylinder head on the die forging machine, preheat the lower mold to 310°C, preheat the upper mold to 270°C, and brush the release agent inside the upper and lower molds;

[0032] (2) Heat the 6063 aluminum alloy to 760°C to melt, and keep it for 1 hour for refining;

[0033] (3) Pour the molten aluminum alloy into the lower mold, and pressurize for the first time when the temperature of the aluminum alloy liquid drops to 685°C. The pressurized pressure is 2000t, and pressurize until the aluminum alloy liquid is less than 1mm full of the mold cavity. Stop, pressurization time is 5 seconds;

[0034] (4) When the temperature of the aluminum alloy liquid drops to 600°C, carry out secondary pressurization, and the aluminum alloy liquid fills the mold cavity and maintains the pressure for 20 seconds;

[0035] (5) After the pressure holding is completed, the pressure is removed, and the cylinder head is taken out for water q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com