Composite microbial fertilizer

A technology of compound microorganisms and microbial agents, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of agricultural product quality decline, low fertilizer utilization rate, and production increase effect decline, so as to improve fertilizer utilization rate, improve soil, prevent Effects of Soil Acidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

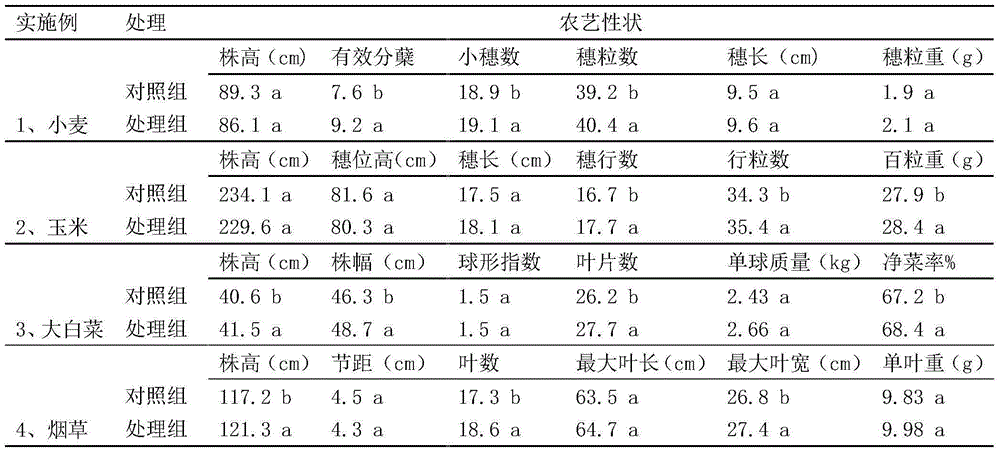

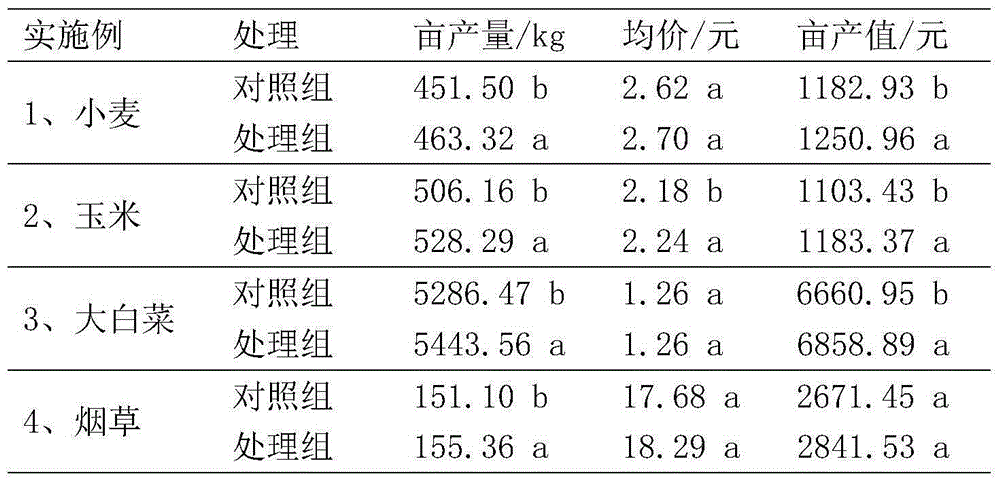

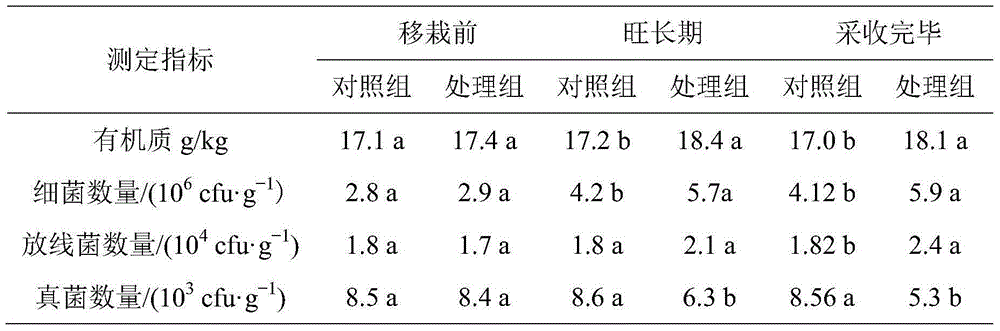

Embodiment 1

[0029] Compound microbial fertilizer was prepared according to the following formula: fermented bean cake 48kg, potassium nitrate 37.5kg, diammonium phosphate 12.5kg, nanometer natto powder 1kg, Bacillus subtilis microbial inoculant 1kg.

[0030] The application test of compound microbial fertilizer was done on wheat in the manner shown in Table 1, and compared with conventional compound fertilizer (Saikefu compound fertilizer 12-08-20 potassium sulfate type). The fertilization methods all adopt 70% (mass ratio) of basal fertilizer in ditches and strips, and 30% (mass ratio) of topdressing fertilizer in holes or strips.

[0031] Table 1 Fertilizer application methods

[0032] deal with

[0033] control group

Embodiment 2

[0035] Compound microbial fertilizer was prepared according to the following formula: fermented bean cake 30kg, potassium nitrate 50kg, diammonium phosphate 15kg, nanometer natto powder 0.5kg, Bacillus subtilis microbial agent 0.5kg.

[0036] The application test of compound microbial fertilizer was done on corn in the manner of Table 1, and compared with conventional compound fertilizer.

Embodiment 3

[0038] Compound microbial fertilizer was prepared according to the following formula: 60 kg of fermented bean cake, 20 kg of potassium nitrate, 20 kg of diammonium phosphate, 2 kg of nanometer natto powder, and 2 kg of Bacillus subtilis microbial agent.

[0039] The application test of compound microbial fertilizer was done on Chinese cabbage in the manner shown in Table 1, and compared with conventional compound fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com