Preparation method of non-shaped obeticholic acid

An obeticholic acid and amorphous technology, applied in the field of preparation of amorphous obeticholic acid, can solve the problems of increased consumption of raw materials, high production cost, poor stability, etc., and achieve long-term preservation, good product stability, The effect of short production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

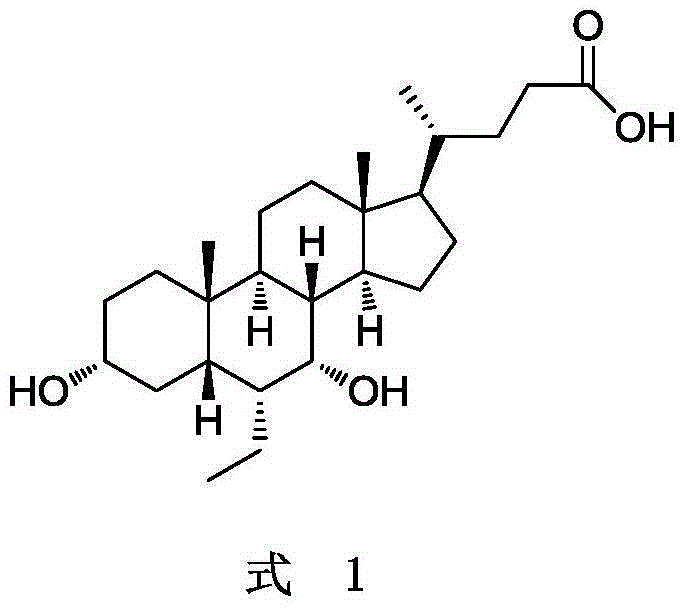

[0031] Obeticholic acid crystal form C samples were prepared according to US Patent US2013 / 0345188A1.

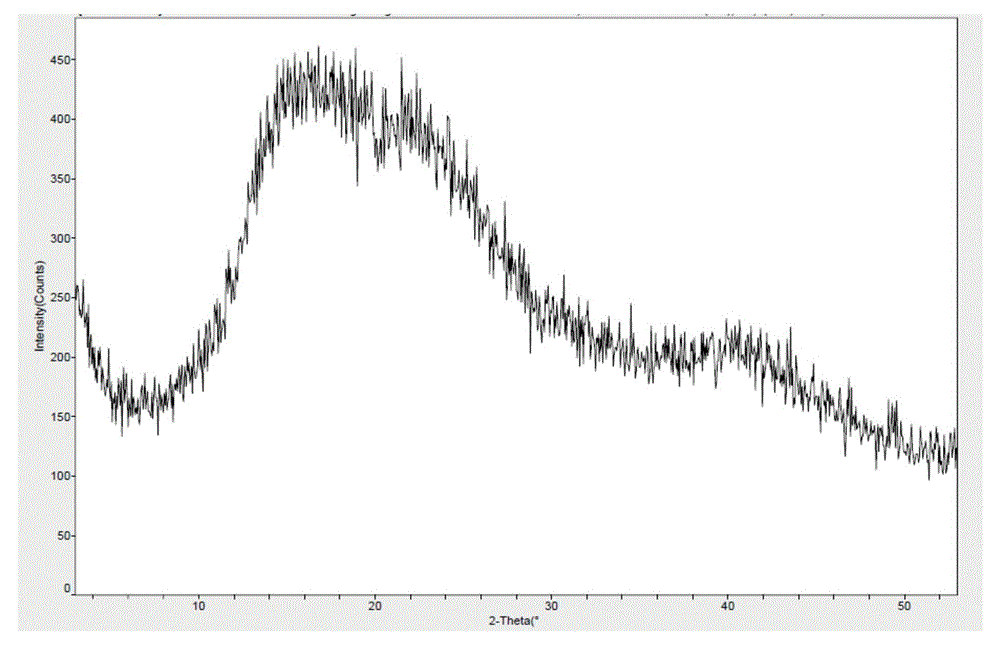

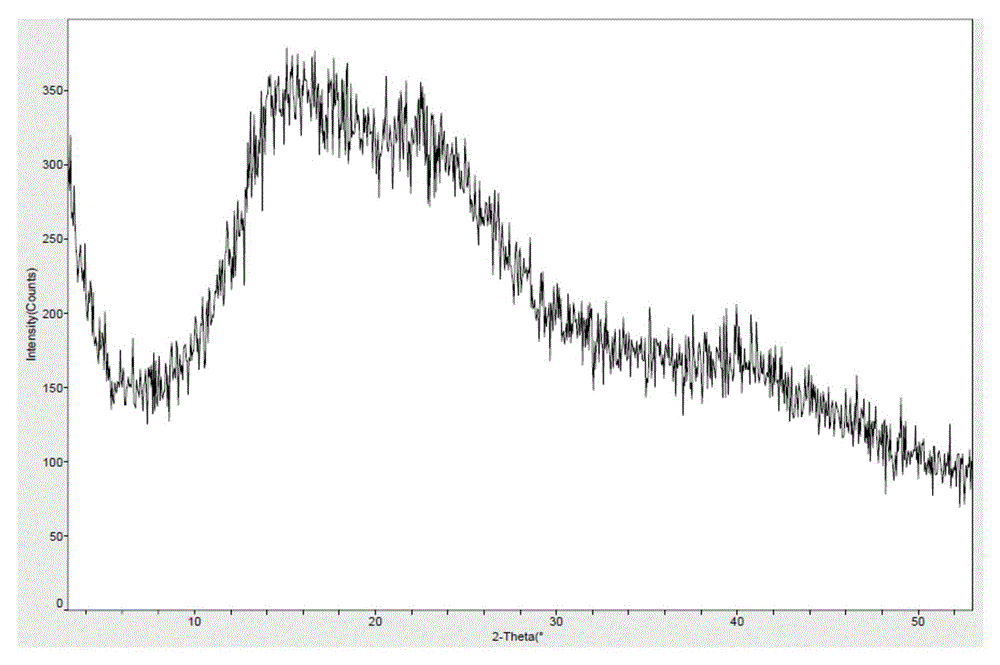

[0032] Dissolve 50.0g of crystal form C of obeticholic acid in 250ml of anhydrous methanol, and obtain a clear obeticholic acid solution after filtration; concentrate under reduced pressure to remove the solvent (vacuum degree is -0.08MPa; concentration temperature is 35°C) to obtain white obeticholic acid Cholic acid solid 49.0g, the yield is 98.0%; The solid is detected by X-powder diffraction as figure 1 shown.

Embodiment 2

[0034] Dissolve 50.0g of obeticholic acid crystal form C in 500ml of acetone, filter to obtain a clear obeticholic acid solution; concentrate under reduced pressure to remove the solvent (vacuum degree is -0.08MPa; concentration temperature is 35°C) to obtain white obeticholic acid Solid 49.2g, the yield is 98.4%; The solid is detected by X-powder diffraction as figure 1 shown.

Embodiment 3

[0036] Dissolve 50.0g of crystal form C of obeticholic acid in 500ml of ethyl acetate, and obtain a clear obeticholic acid solution after filtration; concentrate under reduced pressure to remove the solvent (vacuum degree is -0.08MPa; concentration temperature is 40°C) to obtain white obeticholic acid Cholic acid solid 49.3g, the yield is 98.6%; The solid is detected by X-powder diffraction as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com