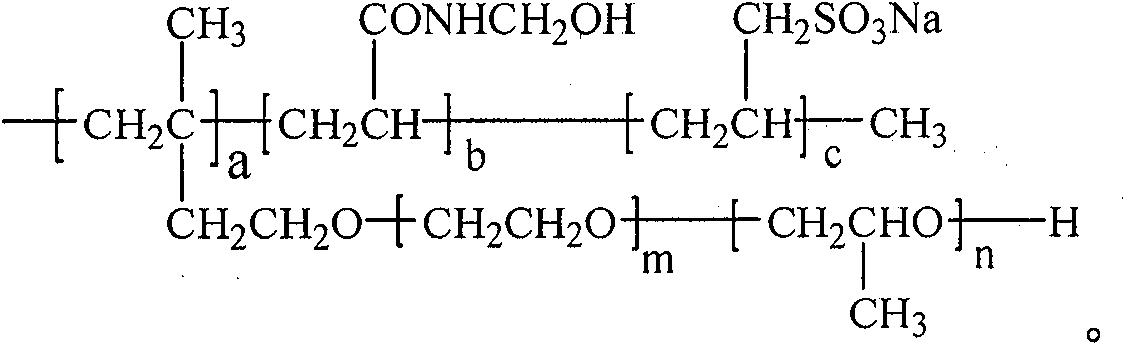

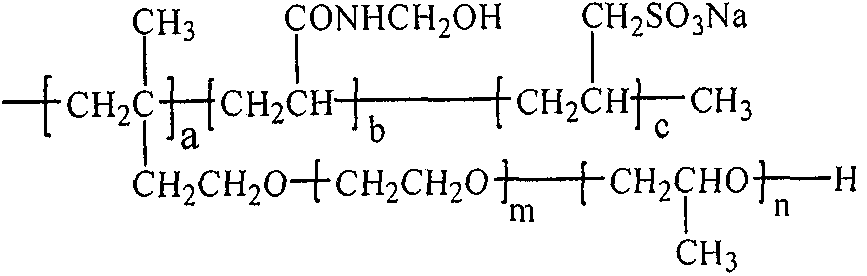

Synthesis and Application of Amide Polyether Sulfonate Sodium Macromolecule for Mold Gypsum Reinforcement

A technology of sodium polyether sulfonate and macromolecules, applied in the field of materials, can solve the problems of unfavorable mechanical strength of gypsum, reduce the water absorption of molds, reduce the strength of gypsum, etc., and achieve the effects of improving the strength of gypsum, reducing the production cost, and reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Using ammonium persulfate as the initiator, three monomers, sodium methacryl sulfonate, methylalkenyl polyoxyethylene polyoxypropylene ether, and N-methylol acrylamide in a molar ratio of 2:6:10, were prepared in At 80°C, the water-phase free radical reaction was carried out for 7h to end. After the product is cooled, it is neutralized with NaOH with a mass fraction of 30% until the pH is 7, and the amide polyether sodium sulfonate macromolecule of the present invention can be obtained. Wherein, the initiator consumption is 0.7%.

[0021] The amide type polyether sodium sulfonate macromolecule synthesized above is added to the required water demand calculated according to the water-to-paste ratio of 0.7 with 0.15% of the gypsum mass to prepare a solution, and the β-hemihydrate gypsum is mixed within 2 minutes. Slowly and evenly add to this solution, and then stand for 1min before making a gypsum mold test piece, remove the mold after final setting, store at room temper...

Embodiment 2

[0026] Using ammonium persulfate as the initiator, three monomers, sodium methacryl sulfonate, methylalkenyl polyoxyethylene polyoxypropylene ether, and N-methylol acrylamide, in a molar ratio of 2:8:15 were prepared in At 80°C, the free radical reaction in water phase was carried out for 8h to end. After the product is cooled, it is neutralized with NaOH with a mass fraction of 30% until the pH is 7, and the amide polyether sodium sulfonate macromolecule of the present invention can be obtained. Wherein, the initiator consumption is 0.6%.

[0027]The amide type polyether sodium sulfonate macromolecule synthesized above is added to the required water demand calculated according to the water-to-paste ratio of 0.7 with 0.15% of the gypsum mass to prepare a solution, and the β-hemihydrate gypsum is mixed within 2 minutes. Slowly and evenly add to this solution, and then stand for 1min before making a gypsum mold test piece, remove the mold after final setting, store at room temp...

Embodiment 3

[0033] Using ammonium persulfate as an initiator, three monomers, sodium methacryl sulfonate, methylalkenyl polyoxyethylene polyoxypropylene ether, and N-methylol acrylamide, in a molar ratio of 2:10:20 were used in The free radical reaction in water phase was carried out at 90°C for 8h to end. After the product is cooled, it is neutralized with NaOH with a mass fraction of 30% until the pH is 7, and the amide polyether sodium sulfonate macromolecule of the present invention can be obtained. Wherein, the initiator consumption is 0.4%.

[0034] The amide type polyether sodium sulfonate macromolecule synthesized above is added to the required water demand calculated according to the water-to-paste ratio of 0.7 with 0.15% of the gypsum mass to prepare a solution, and the β-hemihydrate gypsum is mixed within 2 minutes. Slowly and evenly add to this solution, and then stand for 1min before making a gypsum mold test piece, remove the mold after final setting, store at room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com