Superheated steam recycling and waste heat utilizing apparatus

A technology of superheated steam and steam, which is applied in the fields of industrial energy saving, industrial waste gas recovery and waste heat utilization, and can solve problems such as environmental pollution, human poisoning, energy waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The device will be further described below in conjunction with the accompanying drawings.

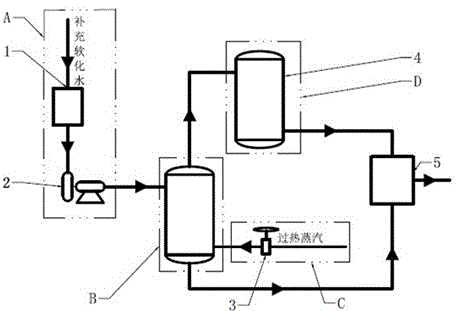

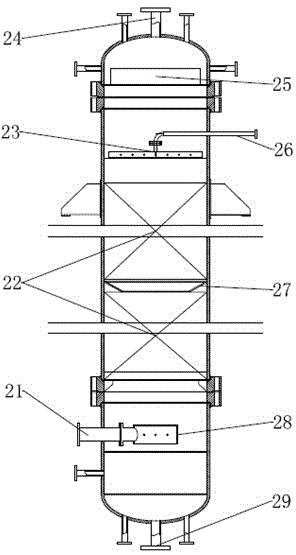

[0012] The present invention is composed of the heating system (D) of the concentration tank, the steam saturated packed tower (B) and the superheated steam supply system (C) and the cooling water supply system (A) used in conjunction with it, such as figure 1 As shown; this device realizes superheated steam recovery and waste heat utilization technology, and applies steam phase change technology to actual industrial production. The superheated steam generated in the industrial production of nylon 66 is recovered by a steam saturation tower, converted into saturated steam and utilized , form a heating system that uses saturated steam to heat the concentration tank (4), replace the biphenyl heating system in the original concentration tank heating system (D), and ensure that the temperature of the nylon 66 salt solution in the concentration tank (4) is maintained at the optimum eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com