Adhesion promoter for liquid silicone rubber, and preparation method and application thereof

A technology of adhesion promoter and liquid silicone rubber, which is applied in the direction of adhesives, chemical instruments and methods, non-polymer adhesive additives, etc., can solve the problems of industrial production and popularization and application limitations, complex preparation process, and increased production costs. , to achieve the effect of stable and controllable reaction process, low preparation cost and improved adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

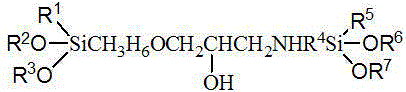

[0017] After mixing the nitrogen-containing silane coupling agent represented by structural formula (I) and the epoxy silane coupling agent represented by structural formula (II) at a molar ratio of 1:1, stir for 30 minutes and slowly heat up to 40°C. After maintaining the reaction for 4 hours, the temperature is lowered, and the obtained colorless transparent liquid is the liquid silicone rubber adhesion promoter shown in the structural formula (Ⅲ). The reaction process is as follows: , where R 1 for -CH 2 CH 3 , R 5 for-OCH 2 CH 3 , R 2 for -CH 3 , R 3 for -CH, R 6 for -CH 2 CH 2 CH 3 , R 7 for -CH 2 CH 2 CH 3, R 4 for -CH 2 CH 2 -.

[0018] Adhesion test:

[0019] In 1000g viscosity is 10000mPa?s, by CH 2 =CH(CH 3 ) 2 SiO 1 / 2 Add 300g of polydimethylsiloxane with a specific surface area of 200m 2 / g of fumed silica, 50g of hexamethyldisilazane and 20g of water, after kneading evenly in a kneader, continue kneading at 170°C for 2 hours under reduc...

Embodiment 2

[0023] Mix the nitrogen-containing silane coupling agent shown in structural formula (I) with the epoxy silane coupling agent shown in structural formula (II) at a molar ratio of 1:1.05, stir for 40 minutes and then slowly heat up to 60°C. After maintaining the reaction for 8 hours, the temperature is lowered, and the obtained colorless transparent liquid is the liquid silicone rubber adhesion promoter shown in the structural formula (Ⅲ). The reaction process is as follows: , where R 1 for -CH 3 , R 5 for-OCH 3 , R 2 for -CH 3 , R 3 for -CH 2 CH 3 , R 6 for -CH 2 CH 3, R 7 for -CH 2 CH 2 CH 3 , R 4 for -CH 2 -.

Embodiment 3

[0025] After mixing the nitrogen-containing silane coupling agent represented by structural formula (I) and the epoxy silane coupling agent represented by structural formula (II) at a molar ratio of 1:1.02, stir for 35 minutes and slowly heat up to 45°C. After maintaining the reaction for 6 hours, the temperature is lowered, and the obtained colorless transparent liquid is the liquid silicone rubber adhesion promoter shown in the structural formula (Ⅲ). The reaction process is as follows: , where R 1 for-OCH 2 CH 3 , R 5 for-OCH 2 CH 2 CH 3 , R 2 for -CH 2 CH 2 CH 3 , R 3 for -CH 2 CH 3 , R 6 for -CH 2 CH 3 , R 7 for -CH 3 , R 4 for -CH 2 CH 2 CH 2 -.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com