Special conditioner for saline-alkali soil white hyacinth bean planting and preparation method and application thereof

A saline-alkali soil and improver technology, applied in the fields of application, soil conditioning materials, chemical instruments and methods, etc., can solve the problems of land occupation and environmental pollution, reduce emissions, promote plant growth, and reduce ammonia volatilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

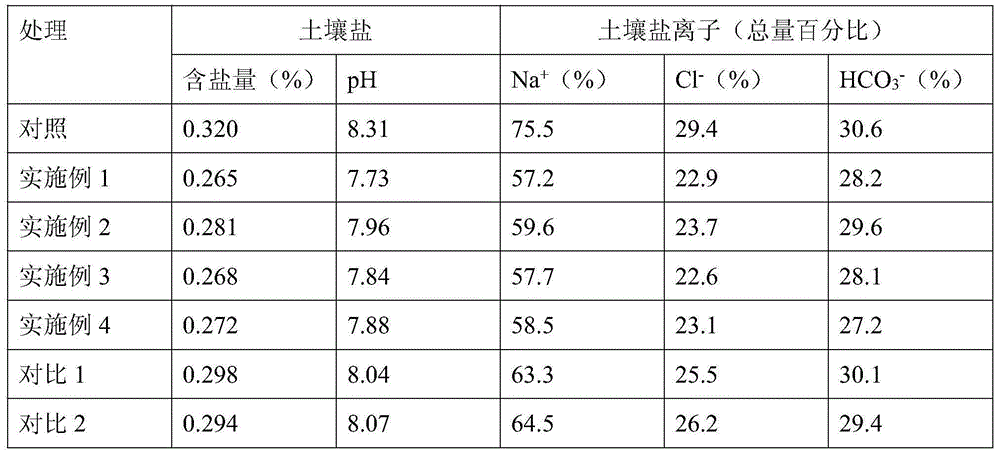

Examples

Embodiment 1

[0056] Formula: phosphogypsum 450kg, chicken and duck manure 120kg, plant ash 150kg, bean dregs 80kg, vegetable dregs 50kg, starch-polyacrylamide compound 100kg

[0057] Preparation method: (1) take 30% of the total amount of phosphogypsum and pulverize it to 170 mesh, and pulverize the remaining phosphogypsum to 140 mesh, and set aside;

[0058] (2) The starch-polyacrylamide compound is pulverized to 140 mesh, and set aside:

[0059] (3) Mix chicken and duck manure, bean dregs, and vegetable dregs with a total amount of 55% evenly, loosely pile them up, and compost at a height of 1.5 meters. Compost and ferment at room temperature for 3-5 days. Evenly sprinkle 30% of the total amount of phosphogypsum powder in step (1) and the remaining chicken and duck manure, plant ash, bean dregs, and vegetable dregs, and ferment again for 15 days. Sealed with film, fermented at 25°C for 50 days, then dried at 130°C, crushed into 140 mesh, and set aside;

Embodiment 2

[0062] Formula: phosphogypsum 350kg, chicken and duck manure 160kg, plant ash 200kg, bean dregs 120kg, vegetable dregs 80kg, starch-polyacrylamide compound 60kg

[0063] Preparation method: (1) take 25% of the total amount of phosphogypsum and pulverize it to 200 mesh, and pulverize the remaining phosphogypsum to 100 mesh, and set aside;

[0064] (2) The starch-polyacrylamide compound is pulverized to 100 mesh, and set aside:

[0065] (3) Mix chicken and duck manure, bean dregs, and vegetable dregs with a total amount of 50% evenly, loosely pile them up, and compost at a height of 1 meter. Compost and ferment at room temperature for 3-5 days. Evenly sprinkle the phosphogypsum powder of step (1) with a total amount of 25% and the remaining chicken and duck manure, plant ash, bean dregs, vegetable dregs, ferment for 10 days again, turn the pile twice during the period, then compact the compost, and use soil or The film is sealed, fermented at 15°C for 60 days, then dried at 150...

Embodiment 3

[0068] Formula: phosphogypsum 550kg, chicken and duck manure 80kg, plant ash 100kg, bean dregs 50kg, vegetable dregs 20kg, starch-polyacrylamide compound 140kg

[0069] Preparation method: (1) Take 35% of the total amount of phosphogypsum and pulverize to 140 mesh, and the remaining phosphogypsum is pulverized to 170 mesh, and set aside;

[0070] (2) The starch-polyacrylamide compound is pulverized to 170 mesh, and set aside:

[0071] (3) Mix chicken and duck manure, bean dregs, and vegetable dregs with a total amount of 60% evenly, loosely pile them up, and compost at a height of 2 meters. Compost and ferment at room temperature for 3-5 days. Evenly sprinkle 35% of the total amount of phosphogypsum powder in step (1) and the remaining chicken and duck manure, plant ash, bean dregs, and vegetable dregs, and ferment again for 12 days. Sealed with film, fermented at 30°C for 40 days, then dried at 120°C, crushed into 170 mesh, and set aside;

[0072] (4) uniformly mix the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com