Method for evaluating brewing characteristics of different hops in Lager beer brewing

A technology of hops and beer, which is applied in the field of evaluation of the brewing characteristics of hop varieties in lager beer brewing and the performance of hop brewing, and can solve the problems of being unsuitable for light beer consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

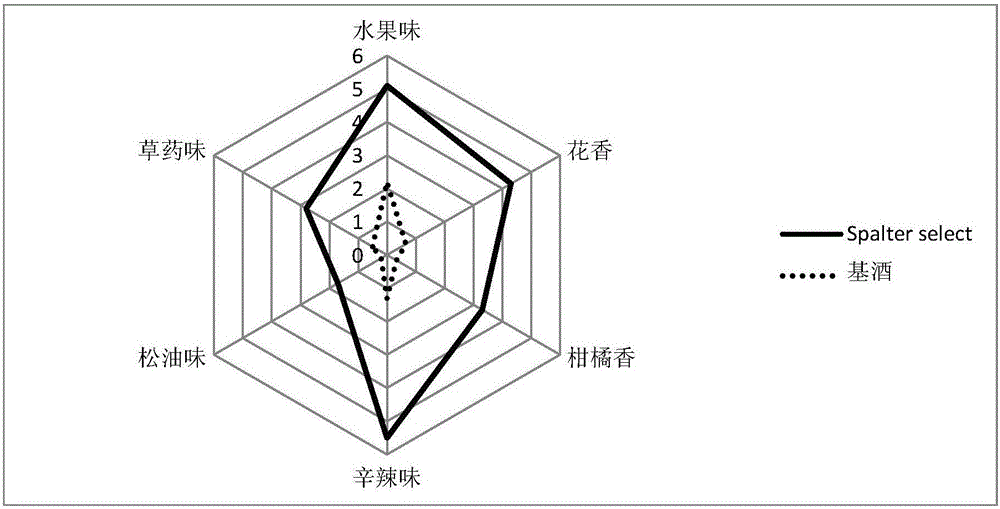

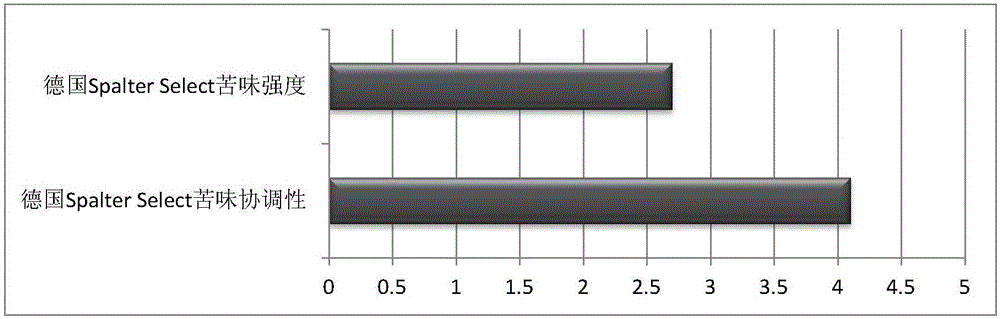

[0030] Embodiment 1: 100L brewing evaluation of German SpalterSelect90 type granular hops

[0031] The method used to evaluate the brewing performance (bitterness and aroma) of German SpalterSelect90 granular hops in Lager beer brewing:

[0032] (1) All light-colored malt saccharification process: use 100% light-colored malt Copland brewed with a store value of 42 and malt with a chroma of 5.2EBC; the hardness of the brewing water is 7 German degrees; the saccharification curve: brewing malt and brewing water according to 1: The ratio of 3.5 was fed at 55°C and kept at a constant temperature for 20 minutes; then the temperature was raised to 65°C at a rate of 1.0°C / min, and the temperature was kept at a constant temperature for 60 minutes; then the temperature was raised to 70°C at a rate of 1.5°C / min, and filtered; the filtered residual sugar was controlled at 2.2;

[0033] (2) The process of adding single-variety hops by boiling twice: boiling at normal pressure for 60 minut...

Embodiment 2

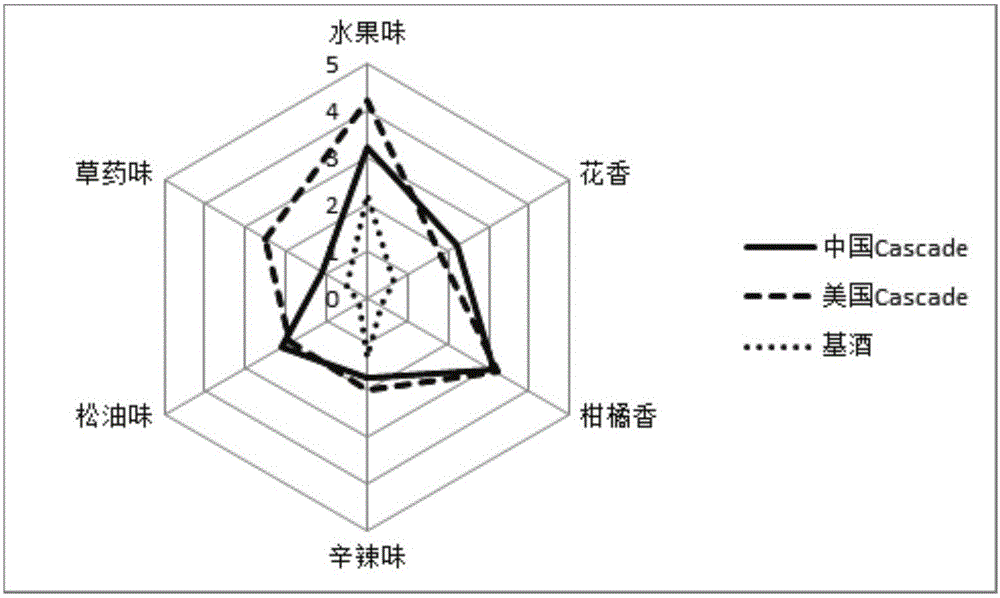

[0044] Example 2: Evaluation and comparison of 100L brewing performance of Cascade hops from different production areas and granulation processes

[0045] The method used to evaluate the brewing performance (bitterness and aroma) of Cascade hops in different production regions and pelleting processes in Lager beer brewing:

[0046] (1) All light-colored malt mashing process: use 100% light-colored malt Copeland brewed with a store value of 42 and malt with a color of 5.2EBC; the hardness of the brewing water is 8 degrees; the saccharification curve: brewing malt and brewing water according to 1: The ratio of 3.8 is 54 degrees, and the temperature is constant for 22 minutes; then the temperature is raised to 64°C at a rate of 1.5°C / min, and the temperature is constant for 65 minutes; ;

[0047] (2) The process of adding single-variety hops by boiling twice: boiling at normal pressure for 60 minutes, and controlling the evaporation rate at 10%.

[0048] Table 3. Aroma and bitt...

Embodiment 3

[0057] Example 3: 100L brewing evaluation of Citra hops

[0058] Methods for Brewing Performance (Bitterness and Aroma) of Citra Hops in Lager Brewing:

[0059] (1) All light-colored malt saccharification process: Brewed with 100% light-colored malt Copeland with a store value of 42 and a chroma of 5.2EBC; the hardness of the brewing water is 6 German degrees; the saccharification curve: brewing malt and brewing water according to 1: The proportion of 3.6 is 56 degrees, and the temperature is kept for 21 minutes; then the temperature is raised to 66°C at a rate of 0.5°C / min, and the temperature is kept at a constant temperature for 55 minutes; then the rate is raised to 70°C at a rate of 1°C / min, and filtered; the filtered residual sugar is controlled at 2.0°P ;

[0060] (2) The process of adding single-variety hops by boiling twice: boiling at normal pressure for 60 minutes, and controlling the evaporation rate at 10%.

[0061] Table 3. Aroma and bitterness index of Citra h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com