Power transmission module for a motor vehicle

A transmission system and motor vehicle technology, applied in the field of transmission system modules, can solve problems affecting KSG efficiency, etc., and achieve the effects of compact structure, improved efficiency, and reduced radial motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

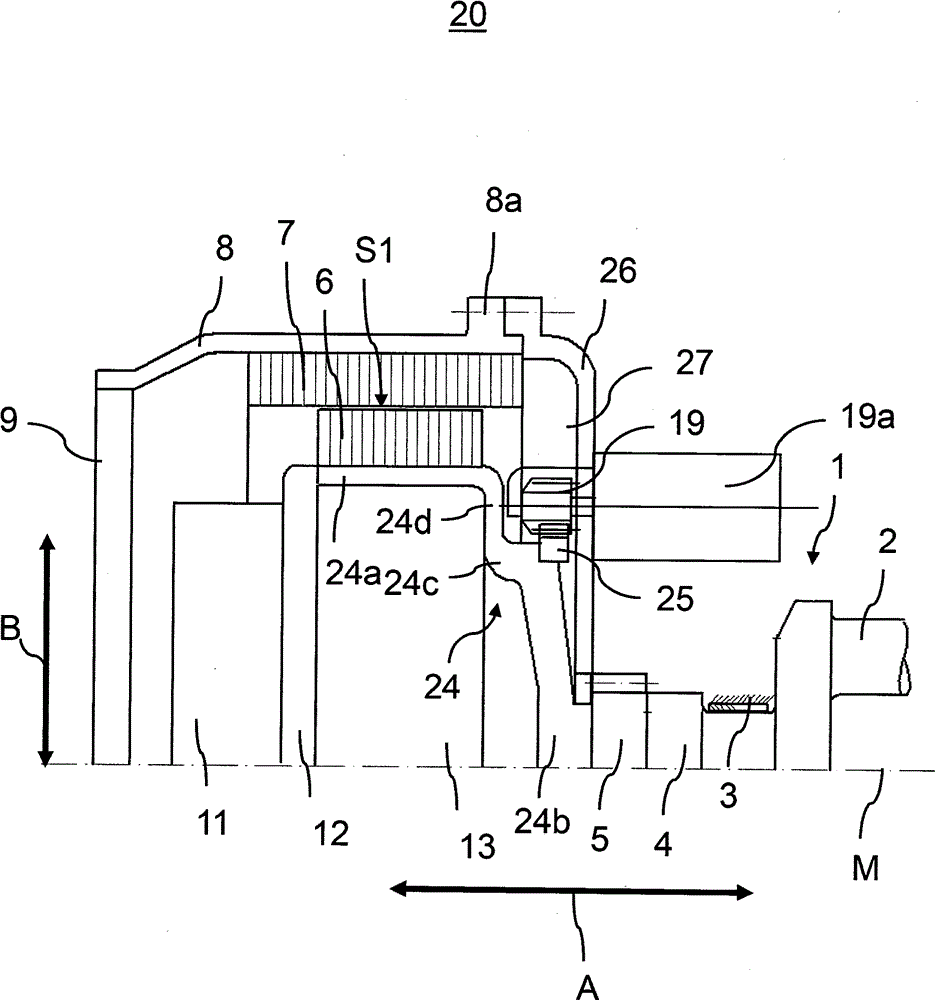

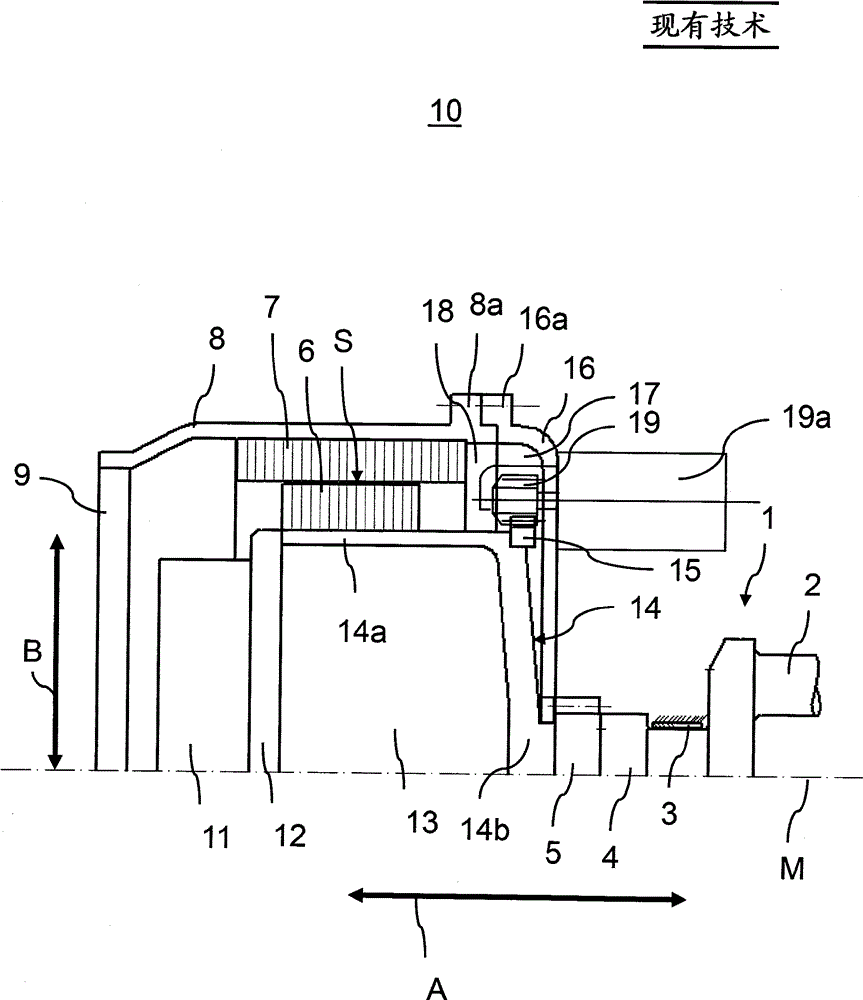

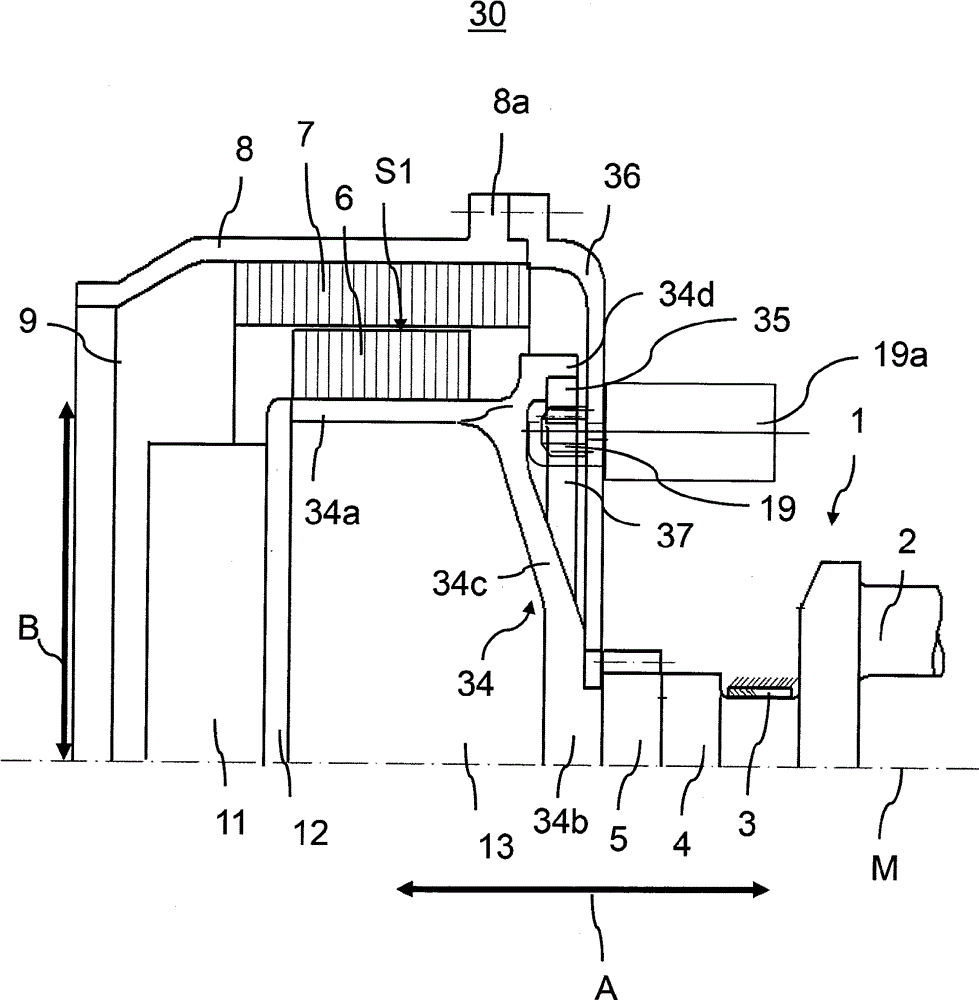

[0087] exist Figures 1 to 4 In each case only the upper half of the drive train module is shown in side view.

[0088] figure 1 A known drive train module for a commercial vehicle is shown. The centerline of the crankshaft is shown with a dotted line M. exist figure 1 Only part of the crankshaft 1 is visible in the figure, in particular the crankshaft bearing 3 , the crank pin 2 for receiving the connecting rod, the flange area 4 and the gear wheel 5 . Via gear 5 , the camshafts can be actuated with defined transmission ratios.

[0089] A cup-shaped flywheel 14 is connected to the crankshaft 1 . The flywheel 14 includes a hollow-cylindrical outer edge region 14 a which extends on the transmission side and on which the annular rotor 6 of the crank-starter generator is arranged in a rotationally fixed manner. The transmission on the output side is not shown, which is in the figure 1 The center is arranged on the left of the drive train module 10 .

[0090] Furthermore, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com