Fiber grating temperature measurement system and method for high overload distribution transformer

A distribution transformer and optical fiber grating technology, which is applied in the field of distribution transformer life cycle prediction, can solve the problem that the sensitivity and accuracy of temperature measurement cannot accurately reflect the continuous change of hot spot temperature rise of high overload distribution transformer windings and the fluctuation of load curve in real time Large and other problems, to achieve the effect of reducing computational complexity, efficient prediction, and improving computational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

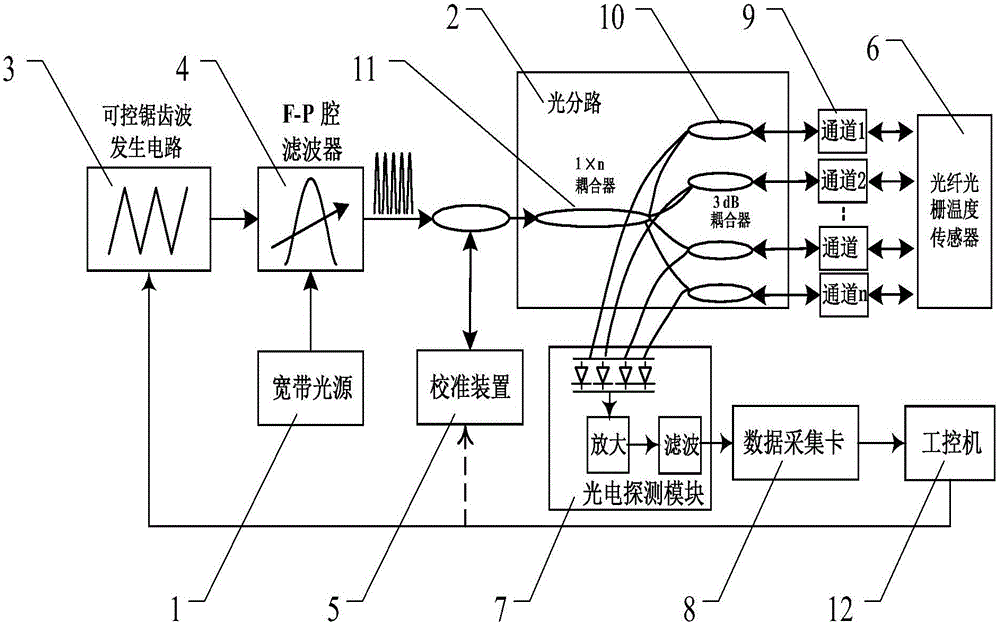

[0038] Such as figure 1 As shown, the fiber grating temperature measurement system of high overload distribution transformer is mainly composed of broadband light source 1, optical splitter 2, controllable sawtooth wave generation circuit 3, F-P cavity filter 4, calibration device 5, grating temperature sensor 6, It consists of a photoelectric detection module 7 and a data acquisition card 8. Among them, the broadband light source 1 provides the system with continuous scanning narrow-band spectrum; the function of optical splitter 2 is to divide the continuous spectrum emitted by the light source into the required number of optical paths; the F-P cavity filter 4 is driven by a controllable sawtooth wave voltage for Demodulate the signal of the sensing grating; the calibration device 5 is used to determine the relationship between the voltage of the adjustable light source and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com