Hard mask composition and method of forming pattern using same

A technology of composition and hard mask, which is applied in the photolithographic process of patterned surface, photosensitive materials used in optomechanical equipment, instruments, etc., can solve the problems such as difficulty in providing clear and fine patterns, so as to ensure heat resistance and the effect of etch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

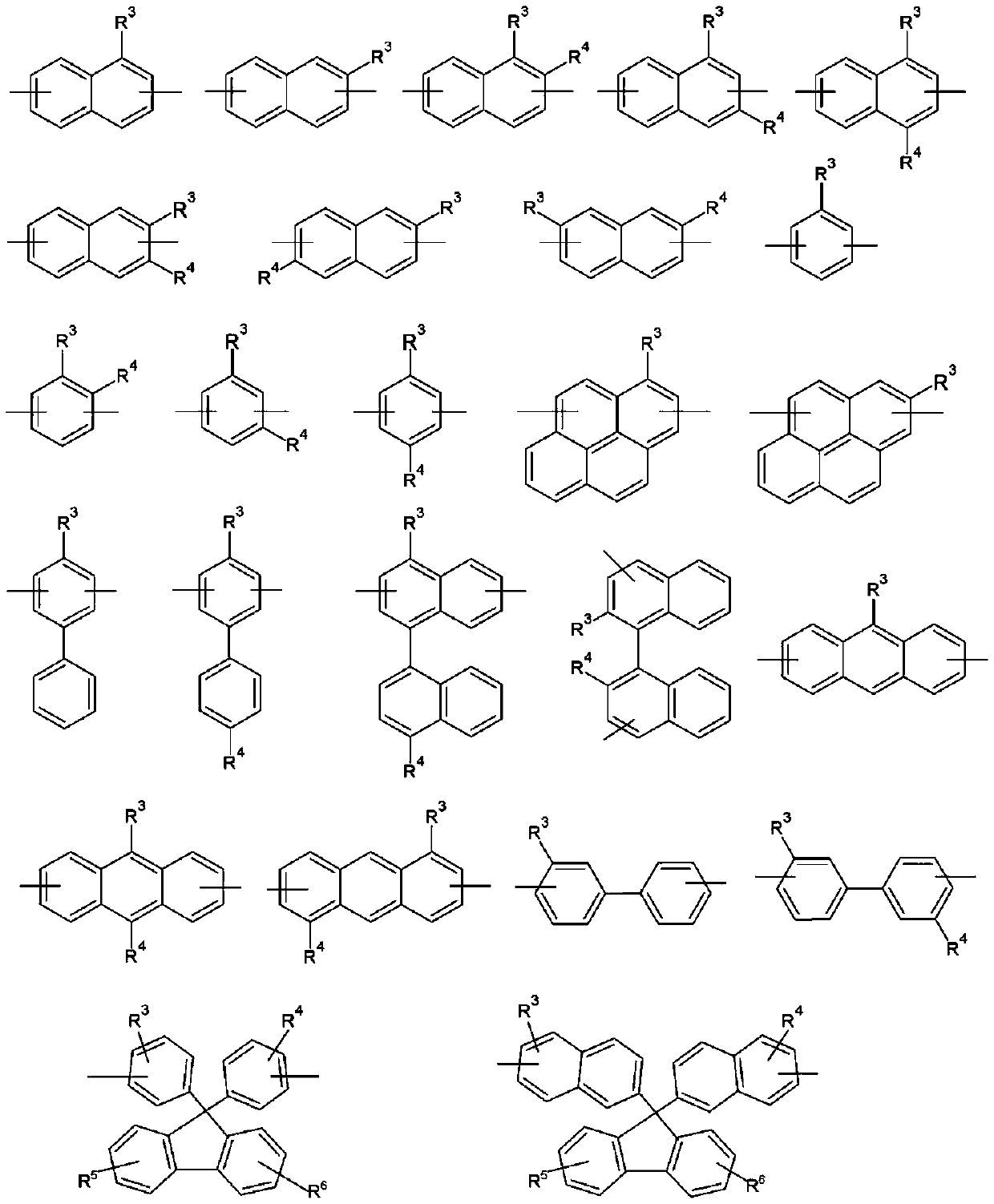

[0110] 21.83 grams of hydroxypyrene, 25.81 grams of 4,4'-bismethylmethoxy-diphenyl ether, 1.23 grams of diethyl sulfate and 32.58 grams of propylene glycol monomethyl ether acetate (PGMEA ) was placed in a flask, and then stirred at 100° C. for 2 hours to 6 hours to conduct a polymerization reaction. The reaction is complete when the weight average molecular weight of the polymer is 2,000 to 3,500. When the polymerization reaction was terminated, the reactant was slowly cooled to room temperature, and added to 40 g of distilled water and 400 g of methanol, and the mixture was vigorously stirred and allowed to stand. After removing the supernatant therefrom, the precipitate generated therein was dissolved in 80 g of cyclohexanone, and the solution was vigorously stirred using 320 g of methanol and allowed to stand (first process). Then, after removing the resulting supernatant therefrom again, the precipitate therein was dissolved again in 80 g of cyclohexanone (second process...

Synthetic example 2

[0114] 22.53 g of 9,9-bis(6-hydroxy-2-naphthyl)fluorene, 12.91 g of 4,4'-bismethylmethoxy-diphenyl ether, 0.77 g of diethyl sulfate and 59.07 g of propylene glycol mono Methyl ether acetate (PGMEA) was placed in the flask, and then stirred at 100° C. for 5 hours to 12 hours to perform a polymerization reaction. The reaction is complete when the weight average molecular weight of the polymer is 2,000 to 3,500. When the polymerization reaction was terminated, the reactant was cooled to room temperature, and then added to 40 g of distilled water and 400 g of methanol, and the mixture was vigorously stirred and allowed to stand. After removing the supernatant therefrom, the precipitate therein was dissolved in 80 g of cyclohexanone, and the solution was stirred by using 320 g of methanol and allowed to stand (first process). Here, the supernatant was removed therefrom again, and the precipitate therein was dissolved in 80 g of cyclohexanone (second process). The first process an...

Synthetic example 3

[0118] The three-necked flask was immersed in a 100°C oil thermostat. The flask was maintained at the same temperature and stirred by using a stirring magnetic bar. Subsequently, 43.65 grams (0.2 moles) of pyrene-4-ol and 33.24 grams (0.2 moles) of 1,3-bis(methoxymethyl)benzene were placed in the reactor and dissolved in 52 grams of propylene glycol monomethyl ether acetic acid ester (PGMEA). Then, 1.23 g (8 mmol) of diethyl sulfate was added to the reactor.

[0119] Polymerization was performed while maintaining the reactor at 100° C., the weight average molecular weight of the polymerization reactant was measured by taking samples therefrom every hour, and the reaction was completed when the weight average molecular weight reached 3,500 to 4,000.

[0120] When the polymerization reaction was terminated, the reactant was slowly cooled to room temperature, and then added to 30 g of distilled water and 300 g of methanol, and the mixture was vigorously stirred and allowed to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com