Preparation method of sulfonate type water-based polyester-acrylic resin hybrid

A technology of acrylic resin and water-based polyester, applied in the field of coatings, can solve the problems of poor weather resistance and chemical resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

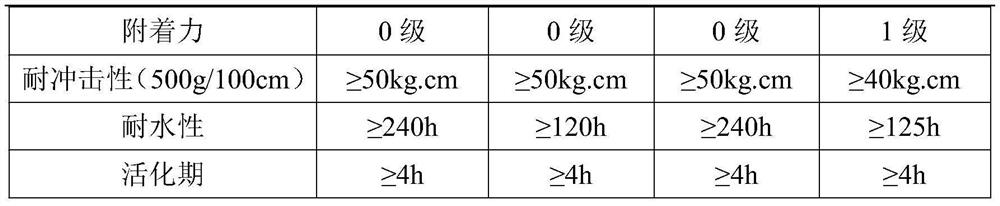

Examples

Embodiment 1

[0031] Step 1, the preparation of polyester intermediate

[0032] Add 62.00 g of isophthalic acid-5-sodium sulfonate, 48.00 g of neopentyl glycol, and 0.200 g of catalyst into a four-necked flask with a stirrer, condenser, water separator, thermocouple and nitrogen inlet. Nitrogen protection, heat up to 160°C for 2 hours, then raise the temperature by 10°C every 0.5h, collect distillates in the water separator until the temperature reaches 200-210°C, keep warm, take samples regularly to measure the acid value, when the acid value drops to 0-5mgKOH / g to stop the reaction, pour the mixed material into a mortar while hot and grind it to powder, and store it under dry conditions to obtain a polyester intermediate.

[0033] Step 2, the synthesis of water-based unsaturated polyester

[0034] Under the protection of nitrogen, 18.00g polyester intermediate, 8.200g neopentyl glycol, 1.900g trimethylolpropane, 6.200g 2-butyl-2 ethyl-1,3-propanediol, 4.600g Phthalic anhydride, 1.390 g...

Embodiment 2

[0038] Step 1, the preparation of polyester intermediate

[0039] Add 62g of isophthalic acid-5-sodium sulfonate, 41.64g of 1,4-butanediol, and 0.0200g of catalyst in a four-necked flask with agitator, condenser, water separator, thermocouple and nitrogen inlet, Introduce nitrogen protection, heat up to 160°C for 2 hours, then raise the temperature by 10°C every 0.5h, collect fractions in the water separator until the temperature reaches 200-210°C, keep warm, take samples regularly to measure the acid value, when the acid value drops to 0 The reaction is stopped at ~5mgKOH / g, and the mixed material is poured into a mortar while it is hot and ground to powder, and stored under dry conditions to obtain a polyester intermediate.

[0040] Step 2, the synthesis of sulfonate type water-based unsaturated polyester

[0041]Under the protection of nitrogen, 30.00g polyester intermediate, 1.900g trimethylolpropane, 6.200g 2-butyl-2 ethyl-1,3-propanediol, 4.600g phthalic anhydride, 1.39...

Embodiment 3

[0045] Step 1, the preparation of polyester intermediate

[0046] Add dimethyl isophthalate-5-sodium sulfonate 62.00g, 1,6-hexanediol 54.60g in the four-necked flask with stirrer, condenser, water separator, thermocouple and nitrogen inlet, Catalyst 0.200g, nitrogen protection, heat up to 160°C for 2 hours, then raise the temperature by 10°C every 0.5h, collect fractions in the water separator until the temperature reaches 200-210°C, keep warm, take samples regularly to measure the acid value, when the acid When the value drops to 0-5mgKOH / g, the reaction is stopped, and the mixed material is poured into a mortar while it is hot, and ground to powder, and stored in a dry condition to obtain a polyester intermediate.

[0047] Synthesis of step disulfonate type water-based unsaturated polyester

[0048] Under the protection of nitrogen, 18.00g polyester intermediate, 9.300g1, 6-hexanediol, 1.900g trimethylolpropane, 6.200g 2-butyl-2 ethyl-1,3-propanediol, 4.600 g of phthalic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com