Ester phosphate electrolysis solvent for dye sensitization solar battery

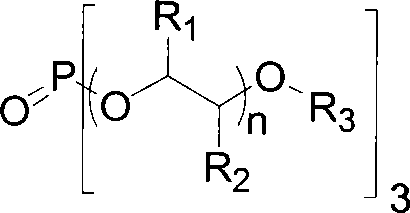

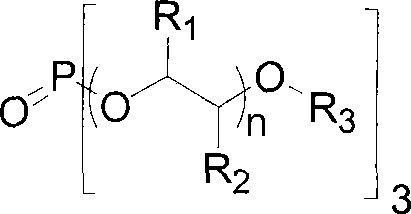

A technology of solar cells and dye sensitization, which is applied in the application field of organic matter in photoelectric conversion technology, can solve the problems of easy volatilization and low boiling point, and achieve the effect of low freezing point, high boiling point and non-volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

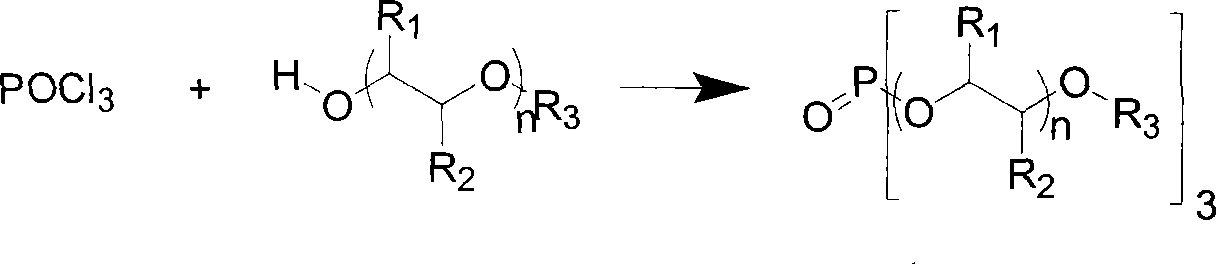

Method used

Image

Examples

Embodiment 1

[0026]

[0027] Preparation of electrolyte solution: Use the compound shown in the figure as the electrolyte solvent, add electrolyte 0.01M 1,2 dimethyl-3-propyl imidazolium iodide salt, 0.01M LiI, 0.04M I 2 . Shake in ultrasonic at room temperature to mix well.

[0028] Preparation of the battery: Then, the titanium dioxide slurry is coated on the treated conductive glass, and after high-temperature treatment, it is immersed in the dye for 14-24 hours of adsorption to form the working electrode of the battery. A dye-sensitized solar cell is prepared by encapsulating the configured electrolyte solution between the working electrode and the platinum-coated counter electrode through a sealant.

[0029] Battery performance test: Lead wires from the working electrode and the counter electrode of the battery respectively, and connect them to the battery performance test device. The working area of the battery passes through a hole with an area of 0.159cm 2 The clapboard is...

Embodiment 2

[0031]

[0032] Preparation of electrolyte solution: Use the compound shown in the figure as the electrolyte solvent, add electrolyte 0.01M 1-methyl-3-butylimidazolium iodide salt, 0.01M NaI, 1M I 2 , 5M 4-tert-butylpyridine. Stir at 50°C to make it evenly mixed.

[0033] Preparation of the battery: Then apply the titanium dioxide slurry on the treated conductive glass, and immerse the dye N after high temperature treatment 3 Adsorbed in medium for 14-24 hours to form the working electrode of the battery. A dye-sensitized solar cell is prepared by encapsulating the configured electrolyte solution between the working electrode and the platinum-coated counter electrode through a sealant.

[0034] Battery performance test: Lead wires from the working electrode and the counter electrode of the battery respectively, and connect them to the battery performance test device. The working area of the battery passes through a hole with an area of 0.159cm 2 The clapboard is dete...

Embodiment 3

[0036]

[0037] Preparation of electrolyte solution: Use the compound shown in the figure as the electrolyte solvent, add electrolyte 0.01M 1-methyl-3-propyl imidazolium iodide salt, 0.01M kI, 0.2M I 2 , 5M crown ether. Stir at room temperature to mix well.

[0038] Preparation of the battery: Then apply the titanium dioxide slurry on the treated conductive glass, immerse in the dye N719 after high temperature treatment and absorb for 14-24 hours to form the working electrode of the battery. A dye-sensitized solar cell is prepared by encapsulating the configured electrolyte solution between the working electrode and the platinum-coated counter electrode through a sealant.

[0039]Battery performance test: Lead wires from the working electrode and the counter electrode of the battery respectively, and connect them to the battery performance test device. The working area of the battery passes through a hole with an area of 0.159cm 2 The clapboard is determined, using a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com