EUV (extreme UV) lithographic apparatus and exposure method therefor

A lithography and exposure bit technology, applied in the field of lithography, can solve the problems of difficult mask heat dissipation, time-consuming, affecting productivity, etc., and achieve the effects of reducing exposure feedback adjustment time, avoiding image quality damage, and improving productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

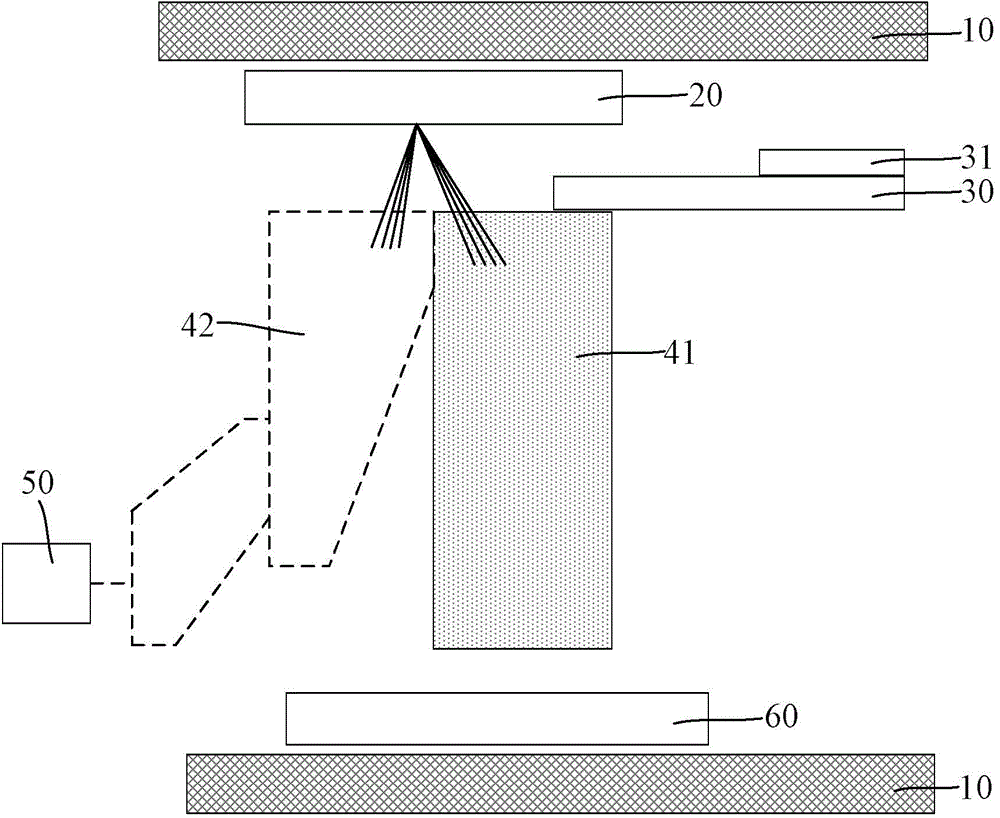

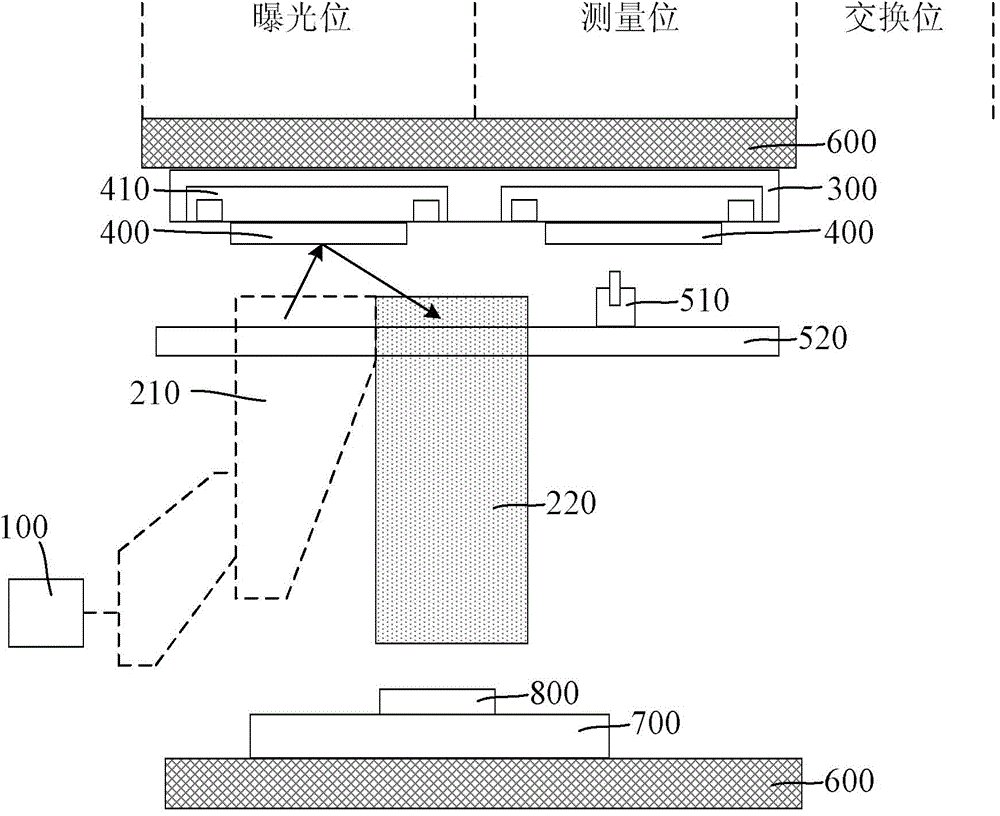

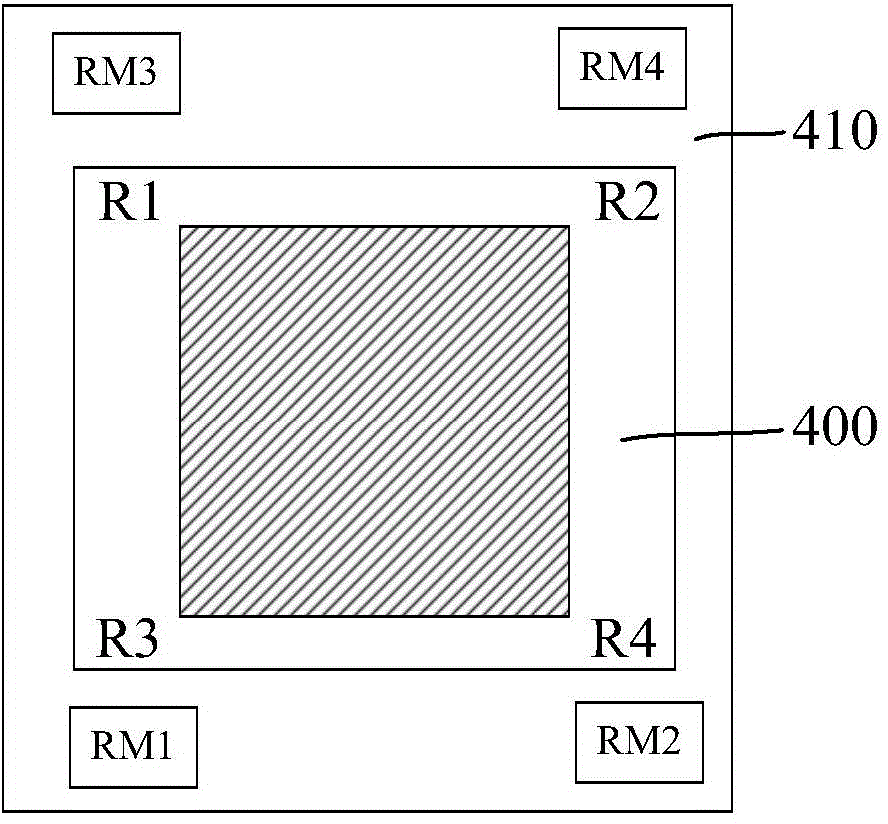

[0045] Please refer to figure 2 In this embodiment, an EUV lithography apparatus is proposed, which includes: EUV light source 100, illumination system 210, projection system 220, workpiece stage 700, mask stage 300, and mask surface type combined measurement system; The EUV lithography apparatus is divided into an exposure position and a measurement position. The projection system 220 and the workpiece table 700 are located in the exposure position, and the mask surface type combined measurement system is located in the measurement position; the mask table 300 carries a plurality of reflective The mask 400, the light emitted by the EUV light source 100 passes through the illumination system 210, the reflective mask 400 on the mask stage, and the projection system 220 to irradiate onto the workpiece stage 700 (as shown by the arrow in the figure). The combined mask surface measurement system measures the surface and position of the reflective mask at the measurement position.

...

Embodiment 2

[0064] Please refer to Figure 5 In this embodiment, an EUV lithography apparatus is proposed. On the basis of the first embodiment, two combined area sensors 510 are provided, which are located at the first measurement position and the second measurement position, respectively. The measurement position and the second measurement position are respectively located on both sides of the exposure position. The mask stage 300 carries three reflective masks 400, and the reflective mask 400 is carried by the mask stage 410 and the mask stage. 300 is connected, one reflective mask 400 is located at the exposure position, and the other two reflective masks 400 are located at the first measurement position and the second measurement position respectively, and are combined with the two combinations of the first measurement position and the second measurement position The area sensor 510 faces each other.

[0065] The EUV lithography apparatus and EUV lithography exposure method proposed in ...

Embodiment 3

[0068] Please refer to Image 6 In this embodiment, an EUV lithography apparatus is proposed, which includes two combined area sensors 510 and two measurement positions. The two measurement positions are the first measurement position and the second measurement position, respectively Both sides of the bit.

[0069] However, in this embodiment, the mask table 300 only carries two reflective masks 400, and the mask table 300 can follow Image 6 The arrow in the middle moves horizontally, so that the two reflective masks 400 can be switched between the first measurement position, the exposure position, and the second measurement position.

[0070] The rest of the device and exposure method are the same as the first embodiment, and will not be repeated here. For details, please refer to the first embodiment.

[0071] In summary, in the EUV lithography apparatus and its exposure method provided by the embodiments of the present invention, since the mask table carries a plurality of refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com