Positive plate and lithium ion battery comprising same

A positive electrode sheet and positive electrode material technology, applied in the direction of batteries, positive electrodes, battery electrodes, etc., can solve the problems of increasing the internal resistance of the battery, increasing the internal resistance, reducing the energy density of the battery, etc. The effect of increasing and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In the preparation method of the above-mentioned positive electrode sheet, the preparation order of the first active material layer and the second active material layer can also be reversed, that is, the second active material layer is first prepared on the positive electrode current collector, and then a buffer layer is formed on the second active material layer. layer, and finally the first active material layer is formed on the buffer layer.

[0045] Another object of the present application is to provide a lithium battery, including the positive electrode sheet provided in the present application.

[0046] Because the lithium-ion battery contains the positive electrode sheet provided by the present application, the lithium-ion battery has good safety performance, for example, it is not easy to catch fire and explode under abuse conditions. In addition, the internal resistance of the lithium-ion battery increases during polarization and discharge. There are few pheno...

Embodiment 1~7

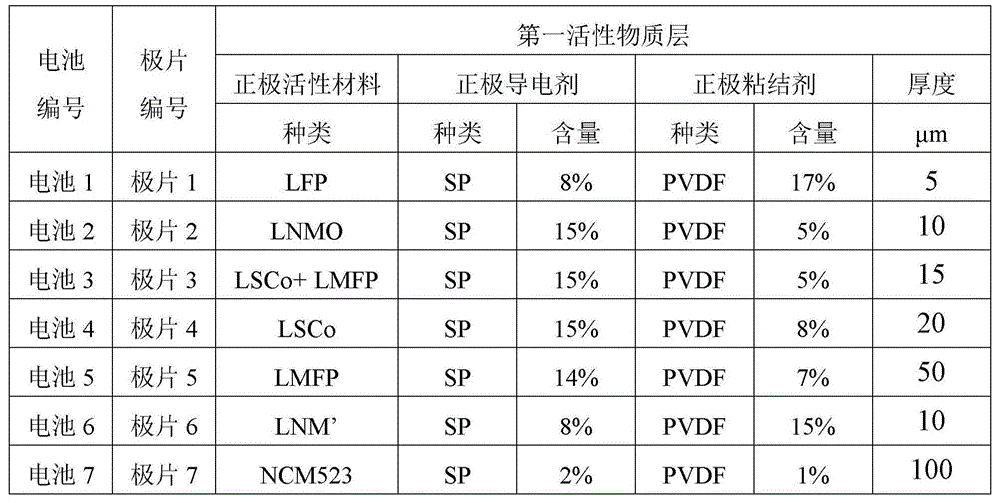

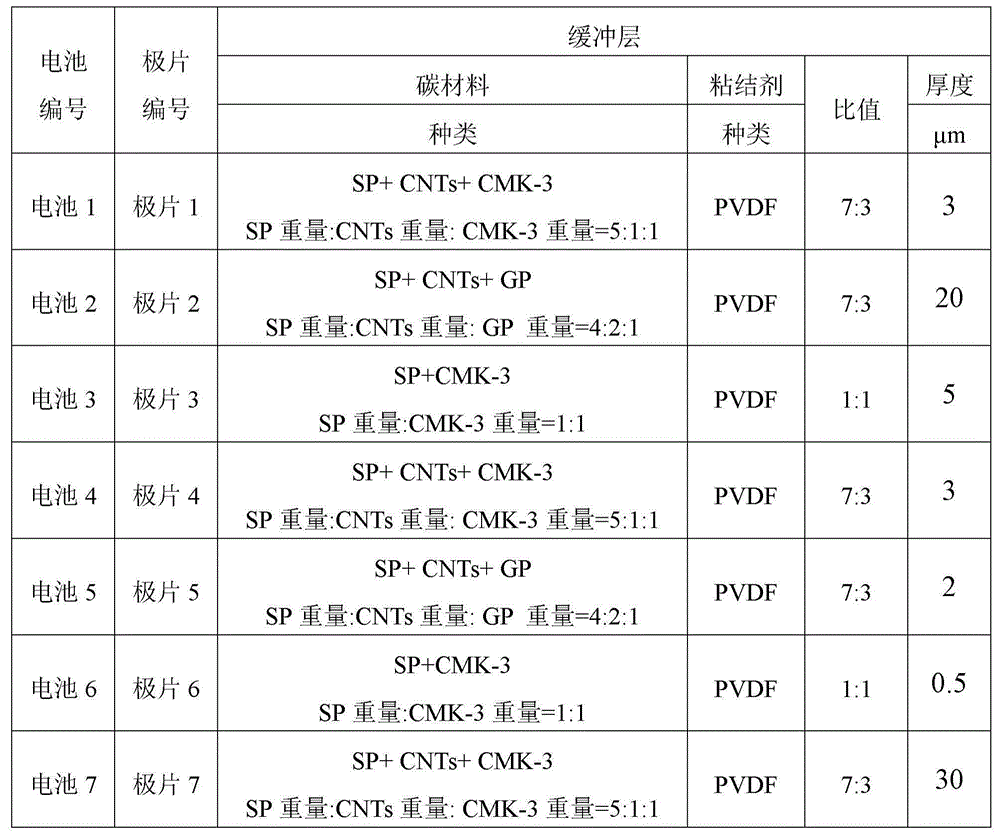

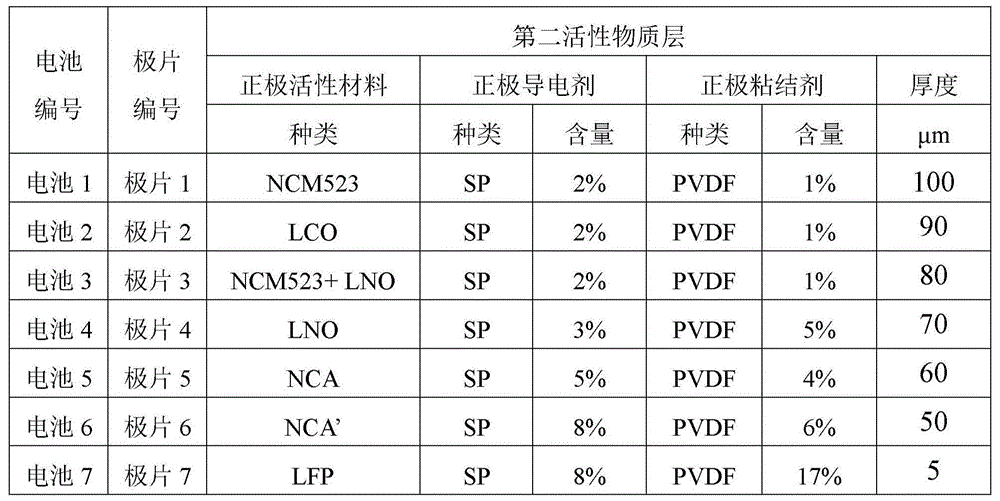

[0061] Preparation of Examples 1-7 Lithium-ion Batteries 1-7

[0062] Lithium-ion batteries (referred to as batteries) 1 to 7 are all prepared according to the following method:

[0063] 1. Preparation of positive electrode sheet

[0064] Positive electrode sheets (abbreviated as electrode sheets) 1 to 7 are prepared according to the following method:

[0065] (1) Add the first positive electrode active material or the second positive electrode active material, the positive electrode conductive agent and the positive electrode binder into the solvent, after mixing uniformly, use a sprayer to coat the uniformly mixed slurry on the positive electrode current collector to form The first active material layer is selected to be dried at 85°C after coating;

[0066] (2) Add the carbon material and the bond to the solvent, and after mixing evenly, coat it on the first active material layer obtained in step (1) to form a buffer layer, wherein, after coating, select the temperature a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com