All-solid-state lithium ion battery and preparation method thereof

A lithium-ion battery, all-solid-state technology, applied in the field of lithium-ion battery preparation technology, can solve problems such as being unsuitable for large-scale production and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

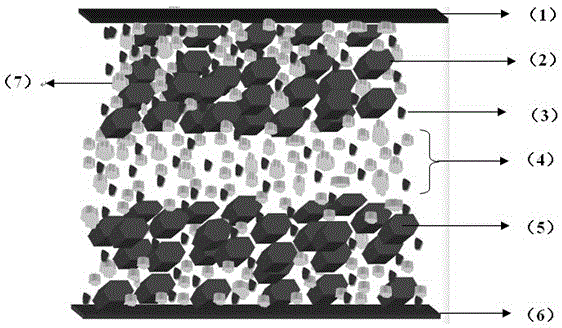

[0026] Such as figure 1 As shown, the inkjet printing all-solid-state lithium-ion battery is composed of positive electrode current collector 1, negative electrode current collector 6, inorganic nanofiller 3, solid electrolyte film layer 4, solid electrolyte particles 7, positive electrode active material 2, and negative electrode active material 5. Each structural unit of the all-solid-state lithium-ion battery is printed by inkjet, and the content of the solid electrolyte in the positive and negative electrodes varies in a gradient in the longitudinal direction.

Embodiment 2

[0028] In the process of inkjet printing, the longitudinal gradient distribution of the solid electrolyte on the electrode: from 50wt.% on the side close to the current collector to 10wt.% on the side close to the middle solid electrolyte film layer, the gradient decreases, and the gradient distribution in the longitudinal direction can maximize The reduced interfacial impedance is beneficial to the migration of lithium ions and improves the electrochemical performance of all-solid-state lithium-ion batteries. Under this gradient change, the capacity properties of active materials can be maximized.

Embodiment 3

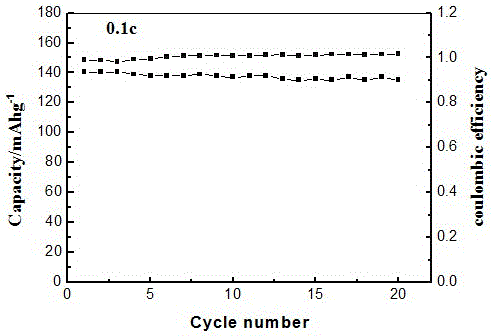

[0030] Inkjet printing combined with physical vapor deposition to prepare all-solid-state lithium-ion batteries. The positive electrode active material uses lithium nickelate, and the negative electrode active material uses lithium titanate, PEO-LiClO 4 -TiO 2 Electrolyte as a solid electrolyte membrane layer material, TiO 2 As an inorganic filler, DMF is used as a solvent to prepare the slurry of each component. The computer designs the inkjet time and sequence of each component in the vertical direction during the printing process, and controls the doping amount of inorganic nano-fillers in the positive and negative electrodes to 5wt.%. , the doping amount in the solid electrolyte membrane layer is 10wt.%, and the thickness of the solid electrolyte membrane layer is 100 μm; after the components are fully dried, use vacuum evaporation technology to vacuum evaporate the aluminum current collector coating on the positive side, and the negative electrode Copper current collecto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com