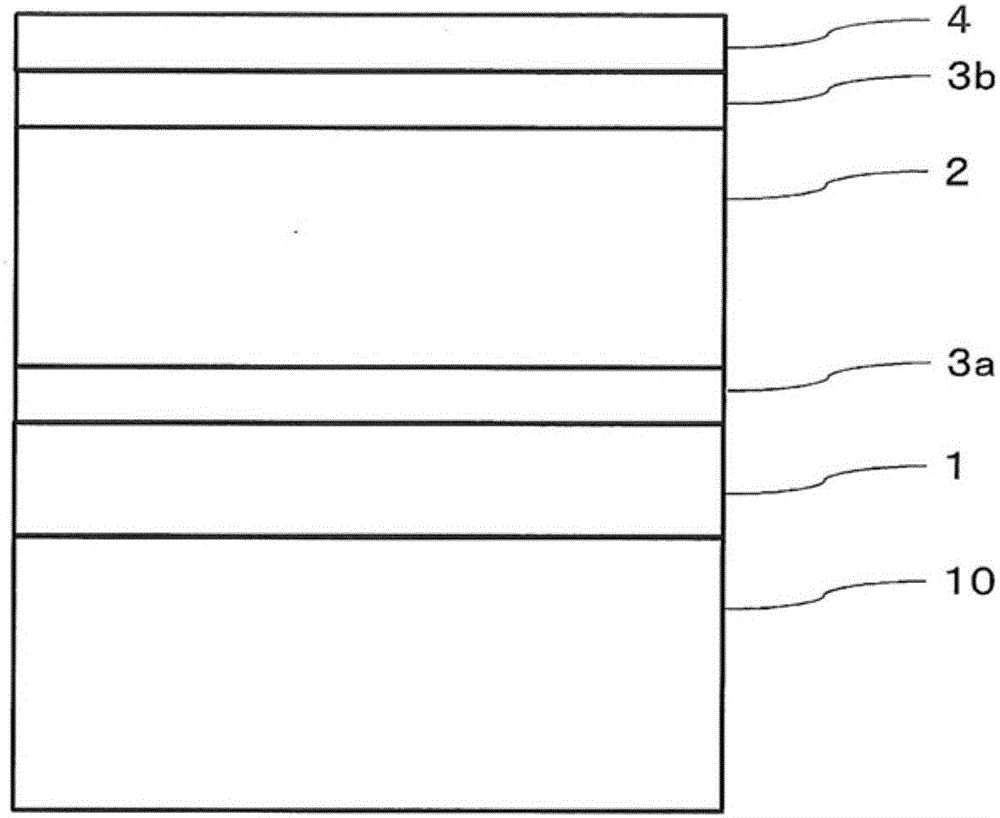

Polarizing plate and image display device

A polarizing plate and polarizing element technology, applied in optics, optical elements, polarizing elements, etc., can solve the problems of uneven display, poor moisture and heat resistance of cellulose ester film, reduced polarization function or color and luster, etc. Shows the effect of suppressing unevenness and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

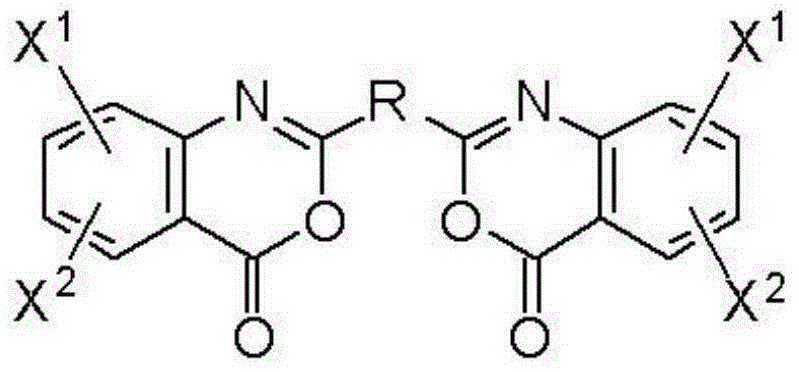

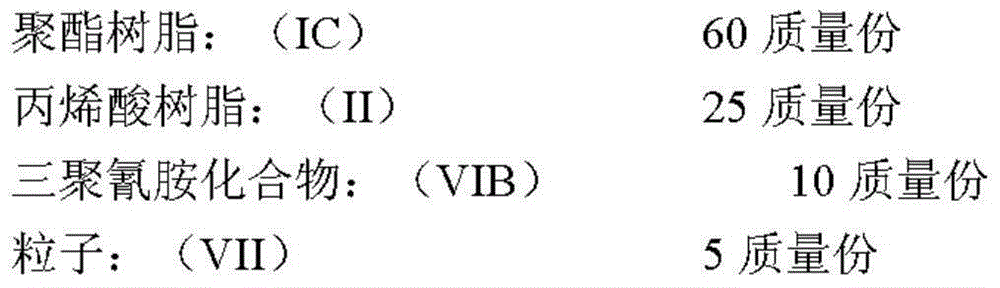

Method used

Image

Examples

Embodiment 1

[0244]

[0245] (raw material polyester 1)

[0246]As shown below, the raw material polyester 1 ( Sb catalyst system PET).

[0247] (1) Esterification reaction

[0248] In the first esterification reaction tank, 4.7 tons of high-purity terephthalic acid and 1.8 tons of ethylene glycol were mixed for 90 minutes to form a slurry, which was continuously supplied to the first esterification reaction tank at a flow rate of 3800 kg / h. Furthermore, an ethylene glycol solution of antimony trioxide was continuously supplied, and the reaction was carried out at an average residence time of about 4.3 hours under stirring at a temperature of 250° C. in the reaction tank. At this time, antimony trioxide was added continuously so that the addition amount of antimony (Sb) might become 150 ppm in element conversion value.

[0249] The reactant was transferred to the second esterification reaction tank, and the reaction was carried out at a temperature of 250° C. in the reaction tank and ...

Embodiment 2~ Embodiment 9

[0338] The polarizing plates of Examples 2 to 9 were produced in the same manner as in Example 1 except that the production conditions were changed as shown in Table 1 below when the polarizing plate of Example 1 was produced. In addition, Re and Rth of the polyester film were controlled to the values in Table 1 below by setting the stretching conditions in the width direction as polarized light.

Embodiment 10

[0340] (easy-adhesive layer including emulsion)

[0341] 35% of UV absorbing emulsion (Nu-Kote UVA-204W: manufactured by Shin-Nakamura Chemical Industry Co., Ltd.) was mixed with the easy-adhesive coating liquid H1 for the easy-adhesive layer on the hard coat side, except Other than that, it carried out similarly to Example 1, and produced the polarizing plate of Example 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com