Gum-penetrating system of bioengineered teeth

A bioengineering and transgingival technology, applied in the field of transgingival systems for bioengineered teeth, can solve the problems of lack of periodontal ligament, implants vulnerable to trauma, time-consuming operation, etc., and achieve the effect of simplifying the surgical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

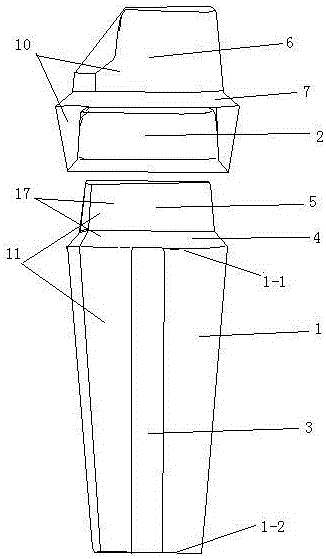

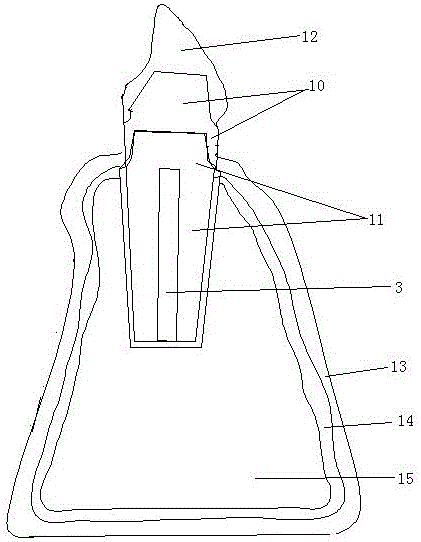

[0028] as attached figure 1 As shown, the design of the bioengineering gingival system includes a bioengineering dental bracket and a gingival abutment.

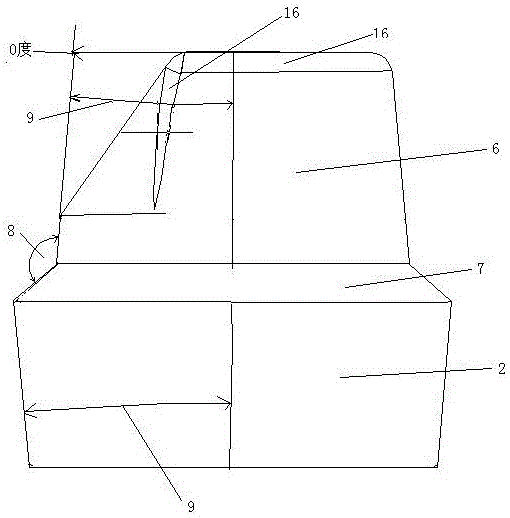

[0029] The lower part of the bioengineering tooth bracket is a bracket structure, and there is a hollow pulp cavity inside. The pulp cavity is conical, wide at the top and narrow at the bottom. It is also conducive to the injection of blood vessels and nerves, ensuring the nutrition of the pulp tissue itself and the regenerated dentin around the pulp cavity, making the texture of the regenerated dentin closer to natural teeth; the diameter of the pulp cavity is 1 / 3 of the diameter of the stent. The shape of the pulp chamber conforms to the shape of the outer frame, and each planar frame corresponds to the shape. The upper part of the bioengineering dental stent is a dental stent abutment with a closed design. There is a pre-prepared 135° dental stent obtuse angle shoulder at the neck of the dental stent abutment. The upper...

Embodiment 2

[0036] Others are as in embodiment 1, wherein the diameter of the pulp cavity is 1 / 2 of the diameter of the bracket, the obtuse angle of the obtuse angle shoulder of the tooth bracket or the obtuse angle shoulder of the crown edge is 130 °, the bonding part of the tooth bracket abutment and the crown are glued The cohesion angle of the knot is 4°.

Embodiment 3

[0038] Others are as in embodiment 1, wherein the diameter of the pulp cavity is 1 / 2.5 of the diameter of the bracket, the obtuse angle of the obtuse shoulder of the dental bracket or the obtuse angle of the crown edge shoulder is 140 °, the bonding part of the dental bracket abutment and the crown are glued The cohesion angle of the knot is 4.5°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com