Multi-cutter cutting machine capable of adding lubricating oil automatically

A technology of automatic adding and lubricating oil, applied in the direction of stone processing equipment, fine working devices, working accessories, etc., to achieve the effect of ensuring lubrication, saving energy and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

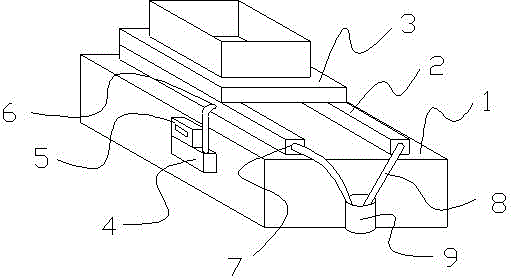

[0014] Such as figure 1 As shown, Embodiment 1 of the present invention: a multi-knife cutting machine capable of automatically adding lubricating oil, comprising a body 1, a guide rail 2, and a tool holder 3, the side wall of the body is fixedly connected with an oil tank 4, a relay 5, and the guide rail 2 is provided with a guide rail oil inlet 6, and the pipe between the guide rail oil inlet 6 and the oil outlet of the fuel tank is connected with the pipeline between the guide rail oil inlet 6 and the oil outlet of the fuel tank. There is a solenoid valve, and the guide rail is also provided with a guide rail oil outlet 7, and an oil pipe 8 is fixedly connected to the oil outlet of the guide rail, and a recovery bucket 9 is fixedly connected to one side of the body, and the oil pipe 8 is provided with an electromagnetic valve. valve.

Embodiment 2

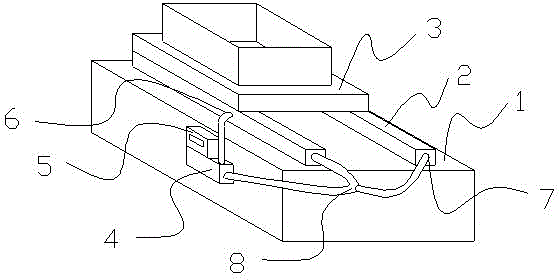

[0015] Such as figure 2 As shown, Embodiment 2 of the present invention: a multi-knife cutting machine capable of automatically adding lubricating oil, including a body 1, a guide rail 2, and a tool holder 3, the side wall of the body is fixedly connected with an oil tank 4, a relay 5, and the guide rail 2 is provided with a guide rail oil inlet 6, and the tube between the guide rail oil inlet 6 and the oil outlet of the fuel tank is connected. The guide rail is also provided with a guide rail oil outlet 7, and the guide rail oil outlet is fixed An oil pipe 8 is connected, and the oil outlet 7 of the guide rail communicates with the oil inlet of the fuel tank through the oil pipe 8, and the oil pipe 8 is provided with a solenoid valve.

[0016] In Embodiment 1 of the present invention, the lubricating oil that enters the guide rail flows out through the oil pipe 8, and a recovery bucket 9 is fixedly connected to one side of the machine body, and the recovery bucket 9 is fixed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap