Viscoelasticity composite sound insulating board

A sound insulation board and viscoelastic technology, applied in the field of multi-layer composite acoustic structures for underwater acoustics, can solve the problem that underwater acoustic materials cannot fully meet the requirements of use, and achieve low cost, reduced reflection echo, and simple molding process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

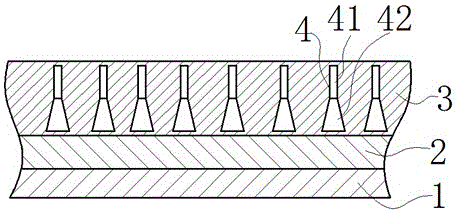

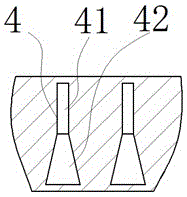

[0022] Such as figure 1 and figure 2 As shown, a viscoelastic composite sound insulation board includes a damping layer 1, a sound insulation layer 2 and a sound absorption layer 3 arranged in sequence, and one side of the damping layer 1 is attached to the shell surface of the underwater moving body , the damping layer 1 is made of isotropic polyurethane or polymer resin, the sound-insulating layer 2 is made of polyolefin elastomer or glass fiber, the sound-absorbing layer 3 is made of photosensitive resin, and the sound-absorbing layer 3 is provided with a closed cavity 4 inside. The damping layer has a thickness of 8 mm to 20 mm, the sound insulation layer has a thickness of 1.2 mm to 1.8 mm, and the sound absorption layer has a thickness of 10 mm to 50 mm.

[0023] In this embodiment, preferably, the damping layer is made of a polyurethane layer with a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com