Tenon and mortise type vehicle frame for battery pack of electric vehicle

An electric vehicle, mortise and tenon technology, applied in the field of mortise and tenon frame, can solve the problems of high cost and production requirements, light weight, no improvement in structural safety, and limited weight reduction effect, so as to improve convenience, The effect of simplifying and improving the life of the parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

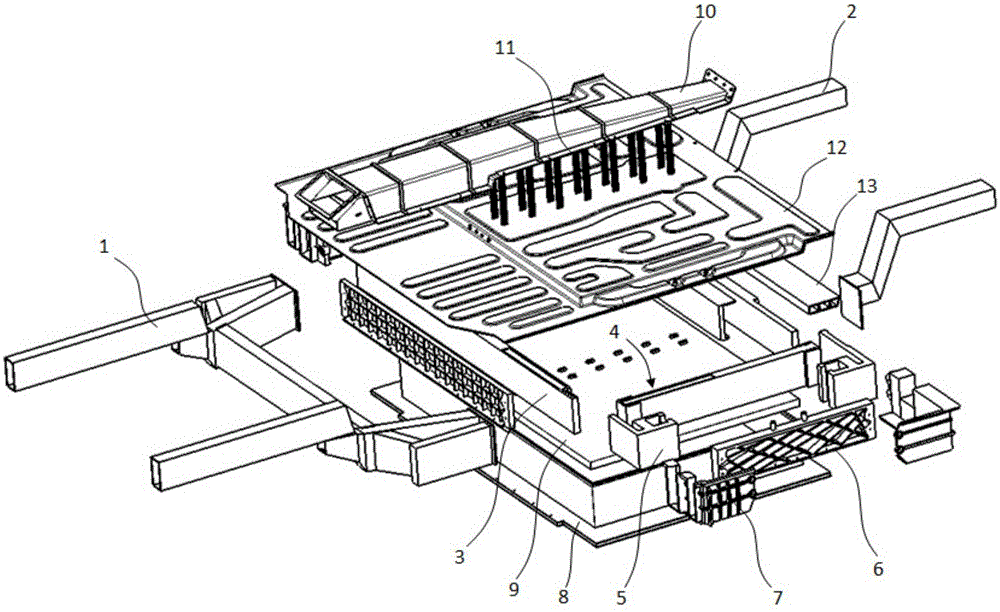

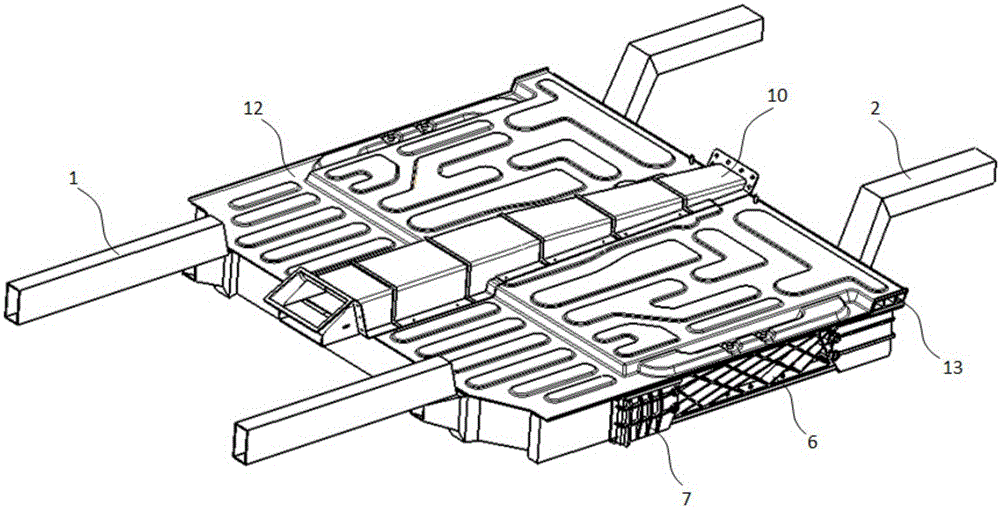

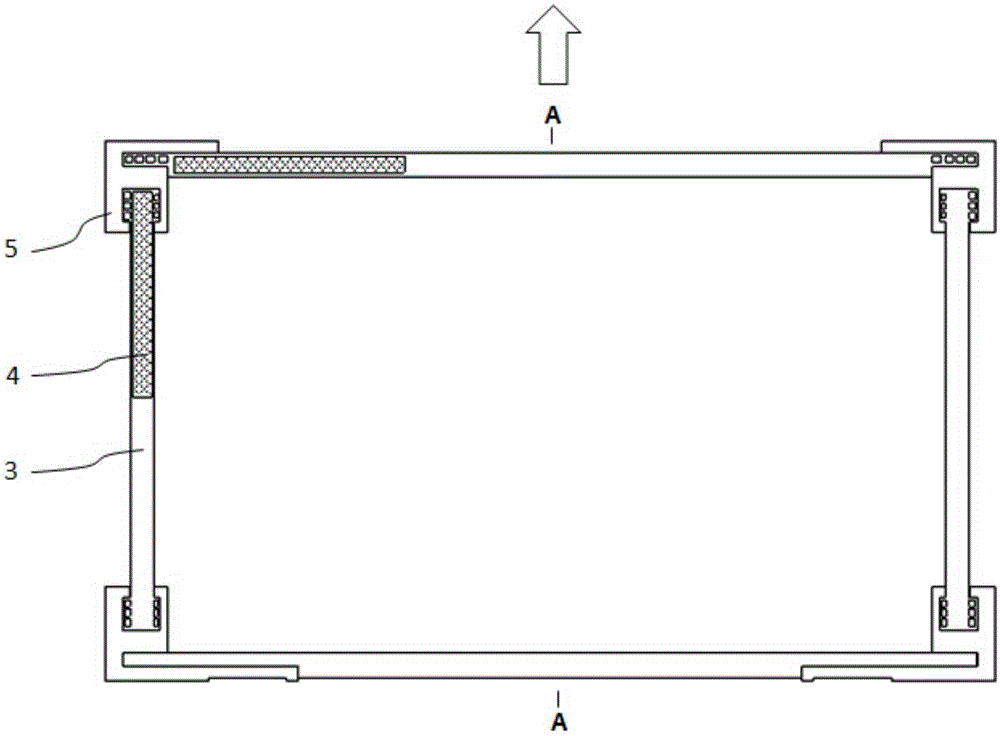

[0035] As shown in Figures 1 to 8. The invention discloses a mortise and tenon frame for an electric vehicle battery pack, which comprises a mortise and tenon frame structure, a battery box 8, an air-cooled heat dissipation structure and a body floor 12, and the mortise and tenon frame structure is fixed on the body The lower part of the floor 12 is fixed on the upper part of the body floor 12 by an air-cooled heat dissipation structure; the body floor 12 is formed by stamping.

[0036] The mortise and tenon frame structure is a frame structure formed by splicing four mortise and tenon tubes 3 through mortise and tenon joints 5, and the mortise and tenon tubes 3 are made of aluminum alloy. When the mortise and tenon frame structure bears static and dynamic stress, it will not produce stress concentration due to the small contact area of the connection position, and at the same time it solves the deformation problem during the welding process of aluminum alloy. The mortise t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com