Heavy load hoisting mechanism used for maintenance of nuclear fusion device parts

A component and hoisting technology, which is applied in the direction of hoisting devices, lifting frames, etc., can solve the problems of large quantity, low utilization rate, and heavy weight, and achieve the effect of continuous work, increased utilization rate, and avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and beneficial techniques of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and specific implementation methods, taking divertor maintenance as an example. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

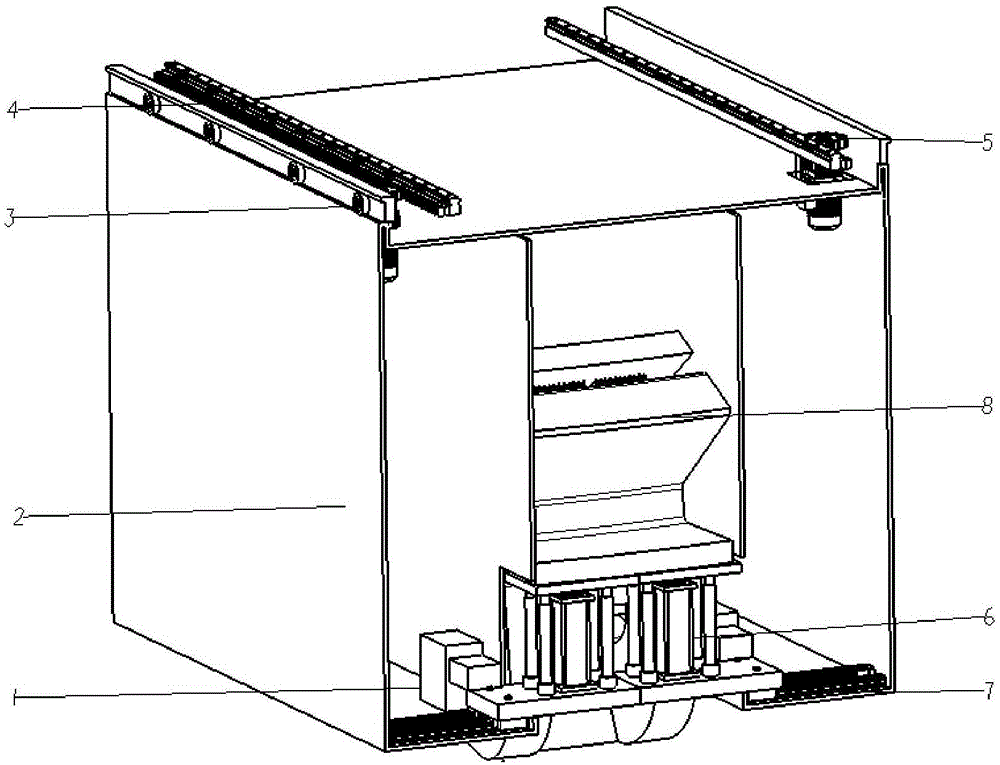

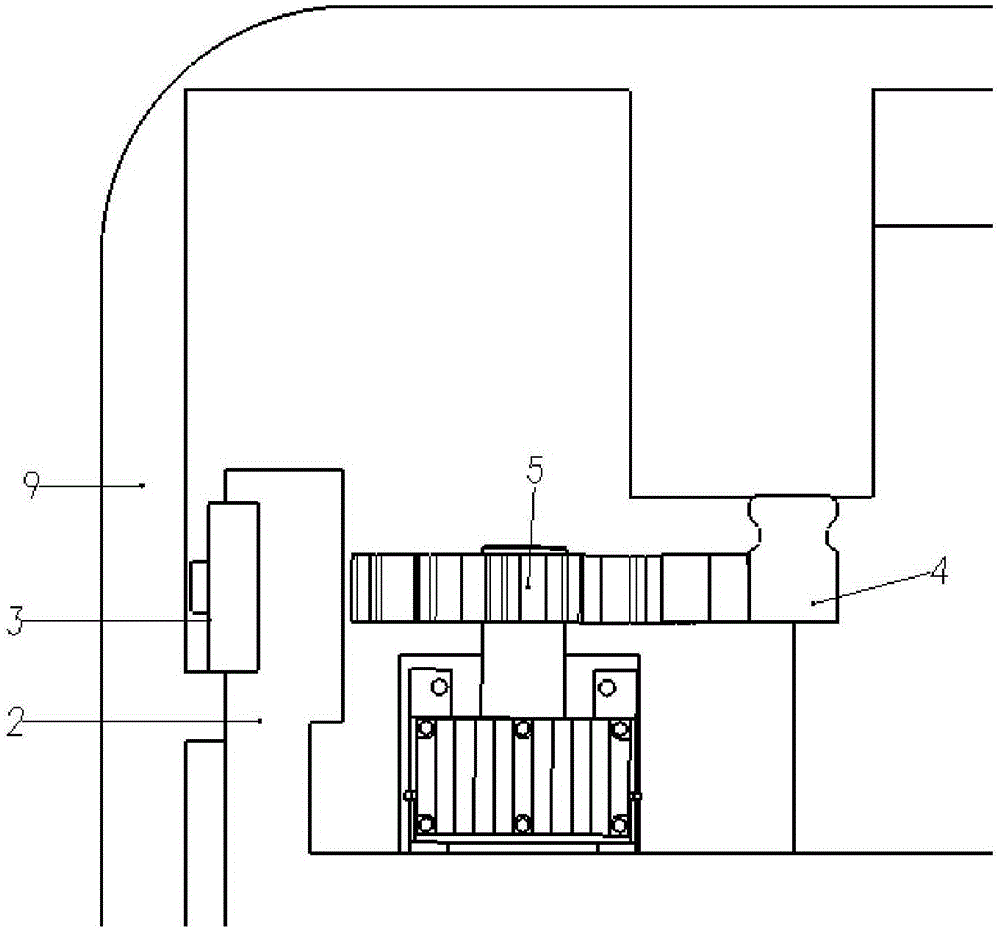

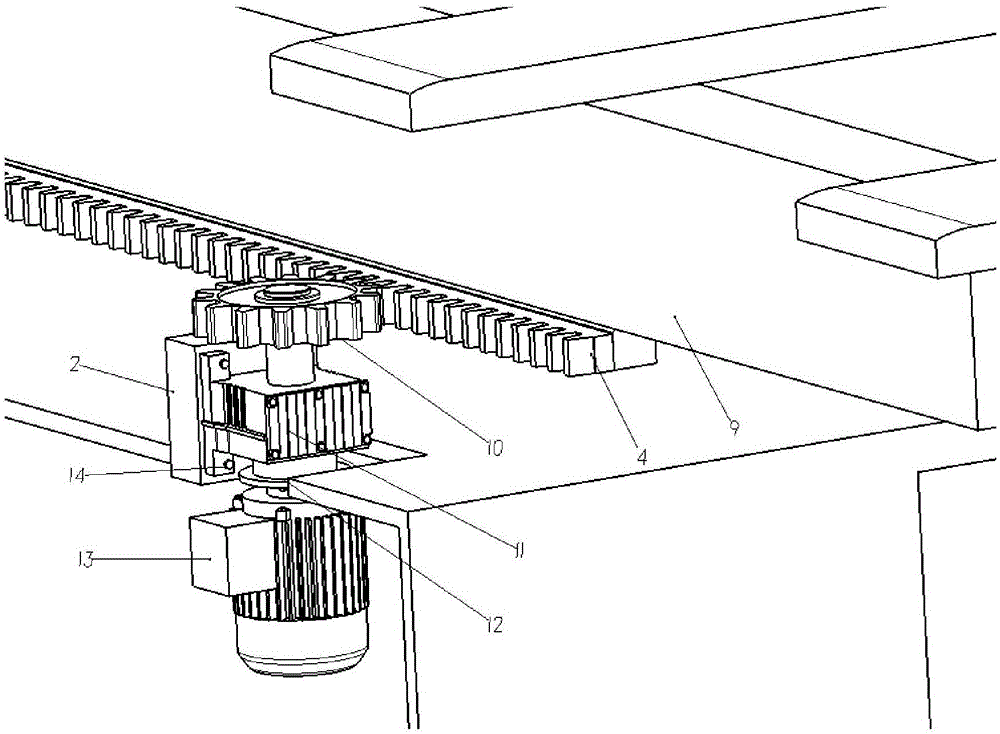

[0020] Such as figure 1 , figure 2 shown. A heavy-duty hoisting mechanism used for maintenance of nuclear fusion device components, including a frame 2, which is provided with a plurality of slots inside to realize the installation and movement of three drive systems, and the two sides of the top of the frame 2 have Four heavy-duty rollers 3 are used to support the entire hoisting mechanism, and at the same time, the sliding friction is converted into rolling friction, which reduces the driving force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com