Graphene/aluminum composite material

An aluminum composite material and composite material technology, applied in the field of graphene/aluminum composite material and its preparation, can solve the problems of deteriorating material performance and achieve the effects of improving dispersion uniformity, low preparation cost, and adjustable and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

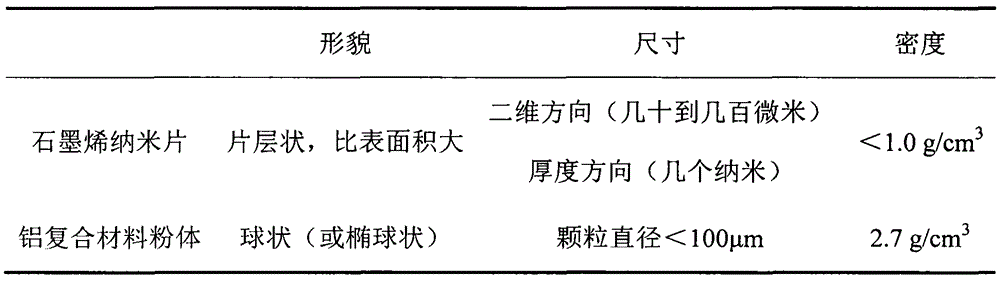

Method used

Image

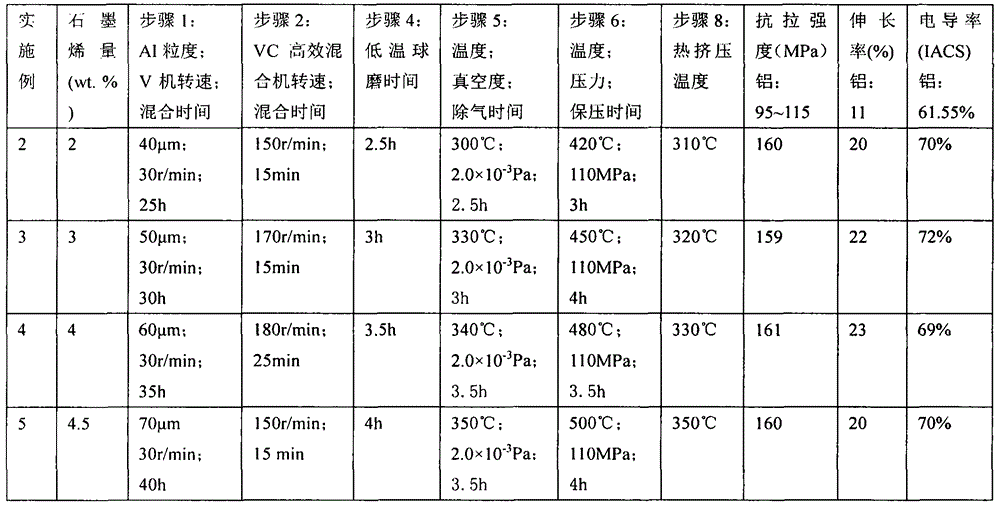

Examples

Embodiment 1

[0039] Get 999 grams of commercially pure Al atomized powder (nitrogen atomization, purity ≥ 99%), and 1 g of graphene (prepared by Hummer's method). The specific preparation process is as follows:

[0040] (1) The pure Al atomized powder with a particle size of 30 μm and the added amount of graphene added is 0.1wt.% of the total amount of the graphene / aluminum composite in a "V" type powder mixer with a speed of 10r / min Mix for 24 hours;

[0041] (2) Put the mixed powder into a VC high-efficiency mixer with a rotating speed of 100r / min and mix for 10min;

[0042] (3) Put the mixed powder, high-carbon chromium bearing steel balls and stearic acid in a stirring ball mill at the same time, fill with liquid nitrogen, and start ball milling when all the balls are submerged in liquid nitrogen. The ball-to-material ratio is 30:1;

[0043] (4) After 2 hours of low-temperature ball milling, take out the powder and place it in an inert gas protection box. After the temperature return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com