No-disturbance carbonization pile forming equipment and construction method thereof

A carbonized pile, non-disturbance technology, applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of insufficient bearing capacity of the pile body, incomplete reaction of magnesium powder, easy bulging, etc., to improve the quality of the pile, The effect of pile formation is good and the service life is increased

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

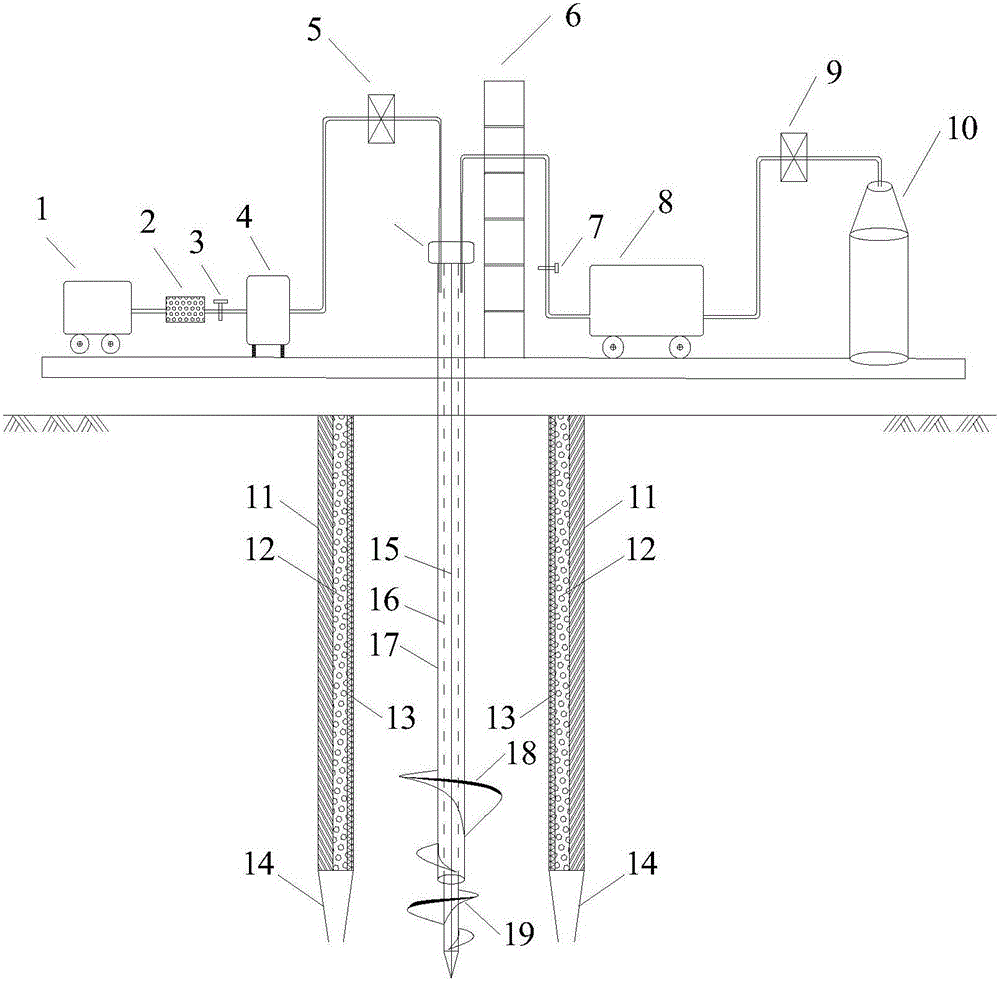

[0043] see figure 1 , The present invention provides a non-disturbance carbonized pile forming equipment, including a curing agent supply device, a foam supply device, and a stirring device 15 .

[0044] The pressure bearing capacity of the curing agent storage tank 4 is 2.1 MPa.

[0045] The foaming device 8 is an anionic surfactant, and its ratio with distilled water is 1:45.

[0046] The rotating speeds of the outer stirring shaft 16 and the inner stirring shaft 17 are both 40r / min, the diameter of the outer rotating blade 18 is 300mm, and the diameter of the inner rotating blade 19 is 200mm.

[0047] High-strength geogrid 13 has a tensile strength of 160kN / m at an elongation of 0.5% 2 .

[0048] The high-strength water film 12 has an internal water pressure of 200kN / m 2 .

[0049] The lifting speed of the stirring device 15 is 0.5m / min.

[0050] The pressure of the carbon dioxide pressure regulating valve is 200kPa.

Embodiment 2

[0051] Embodiment 2: the construction method of undisturbed carbonized pile forming pile, its steps are as follows:

[0052] A) Use bulldozers to level the selected area of the ground surface. Generally, the leveling area should be larger than the area formed between the laid piles. The smoothness of the ground surface is suitable for the smooth operation of the construction machinery platform.

[0053] B) Select pile holes in the leveling area according to the design drawings, a total of 400, and determine the pile length and pile spacing and other indicators. The pile length determined in this example is 20m, and the pile spacing is 4m.

[0054] C) Put the dried curing agent into the curing agent storage tank 4, and carry out gas drying through the drying device, and at the same time, put the foaming agent into the foaming device 8 for carbon dioxide gas foaming.

[0055] D) Move the stirring device 15 to the preset pile position, turn on the stirring device 15 to the pene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Pressure endurance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com