Interference performance clamping plate type cascading test device and method for smoke screen

A testing device and splint-type technology, which is applied in the direction of measuring device, scattering characteristic measurement, material analysis by optical means, etc. Uniform dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

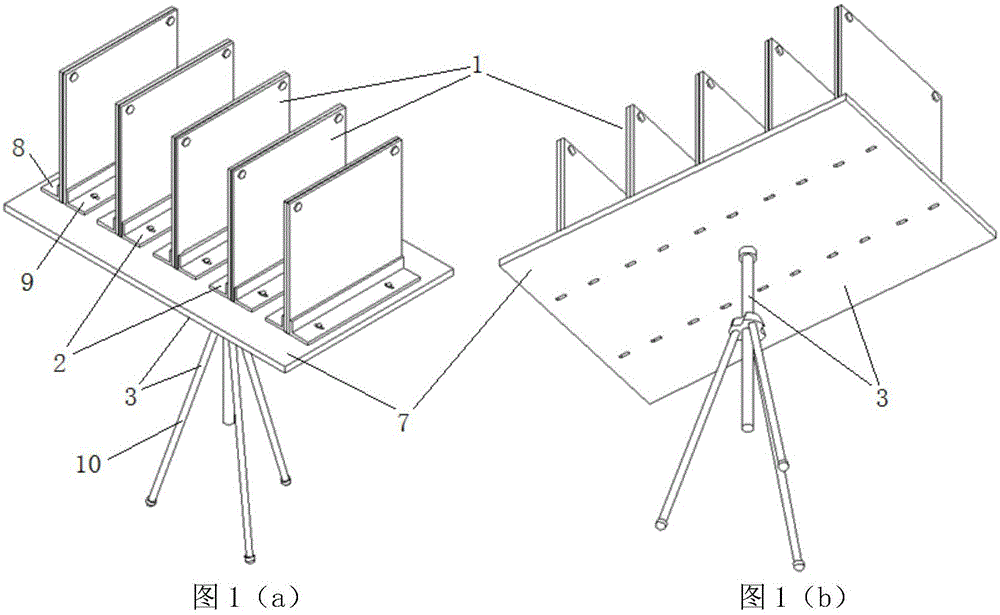

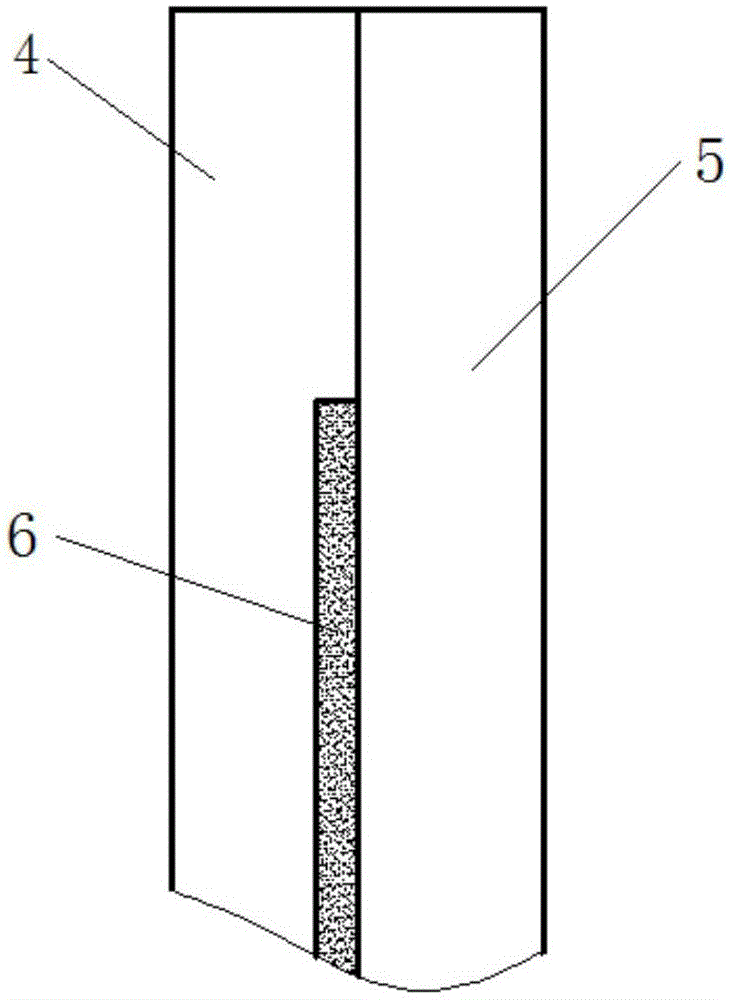

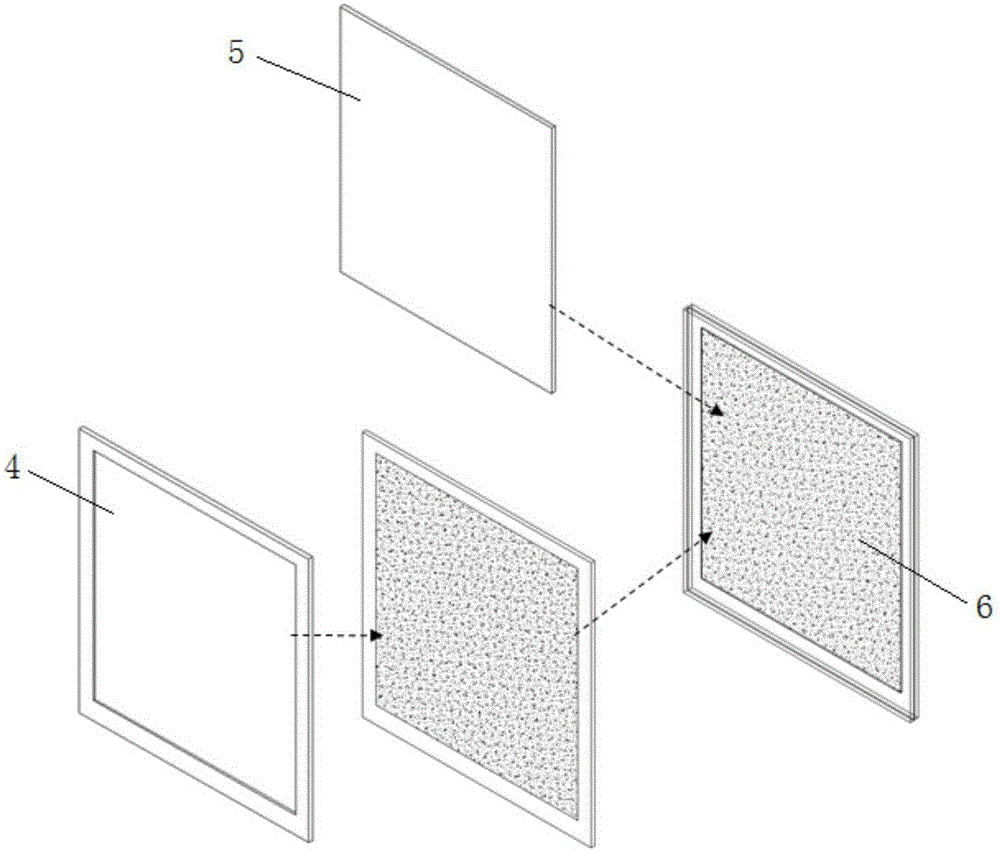

Embodiment 1

[0044]Test material 6 is a smoke screen material that interferes with the laser. The number 1-5 plywood group with shallower cavity depth should be selected. The finer the material particles, the smaller the number of the plywood group should be selected. After the test material is evenly loaded, each part of the test device is assembled in turn, supported on the ground and adjusted firmly. refer to Figure 9 A laser signal transmitter 11 is set up on one side, and a laser power detector 12 is set up on the other side to ensure that the connection between the laser signal transmitter and the center of the signal receiver effectively passes through the area where the test material in the sample splint group is located. When the laser signal emitted by the transmitter 11 passes through the splint set 1 , its intensity will be attenuated by the test material 6 , and the change of its intensity can be quantitatively measured through the receiver 12 on the other side. Comparing th...

Embodiment 2

[0046] Test material 6 is a powder anti-infrared material. The number 1-5 plywood group with shallower cavity depth should be selected. The finer the material particles, the smaller the label of the plywood group should be selected. After the test material is evenly loaded, each part of the test device is assembled in turn, supported on the ground and adjusted firmly. refer to Figure 9 , set up a black body or infrared signal transmitter 11 on one side, and set up an infrared spectroradiometer or other infrared receiver 12 on the other side to ensure that the connection between the infrared signal transmitter and the center of the signal receiver passes through the test material in the sample splint group effectively your region. When the infrared signal emitted by the transmitter 11 passes through the splint set 1 , its intensity will be attenuated by the test material 6 , and the change of its intensity can be quantitatively measured through the receiver 12 on the other si...

Embodiment 3

[0048] Test material 6 is a material that interferes with millimeter-wave smoke screens. The number 6-10 plywood set with a deeper inner cavity should be selected. The larger the material particles, the larger the number of the plywood set should be selected. After the test material is evenly loaded, each part of the test device is assembled in turn, supported on the ground and adjusted firmly. refer to Figure 9 A millimeter wave signal transmitter 11 is erected on one side, and a millimeter wave signal receiver 12 is erected on the other side to ensure that the connection between the millimeter wave signal transmitter and the center of the signal receiver effectively passes through the area where the test material in the sample splint group is located. When the millimeter wave signal emitted by the transmitter 11 passes through the splint set 1 , its intensity will be attenuated by the test material 6 , and the change of its intensity can be quantitatively measured through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com