Discriminating method of natural indigo dyed silk fabric

A natural indigo and silk technology, applied in the field of chemical identification, can solve the problems of low identification degree and large fabric damage, and achieve the effect of high identification success rate, easy to use, and rapid identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

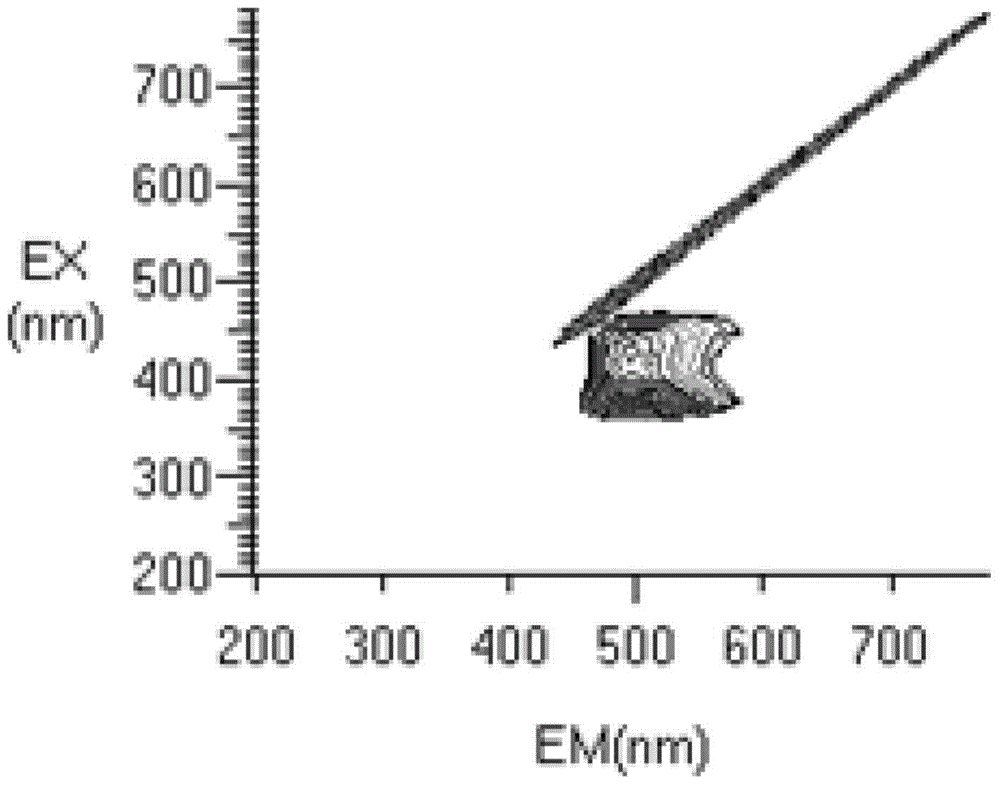

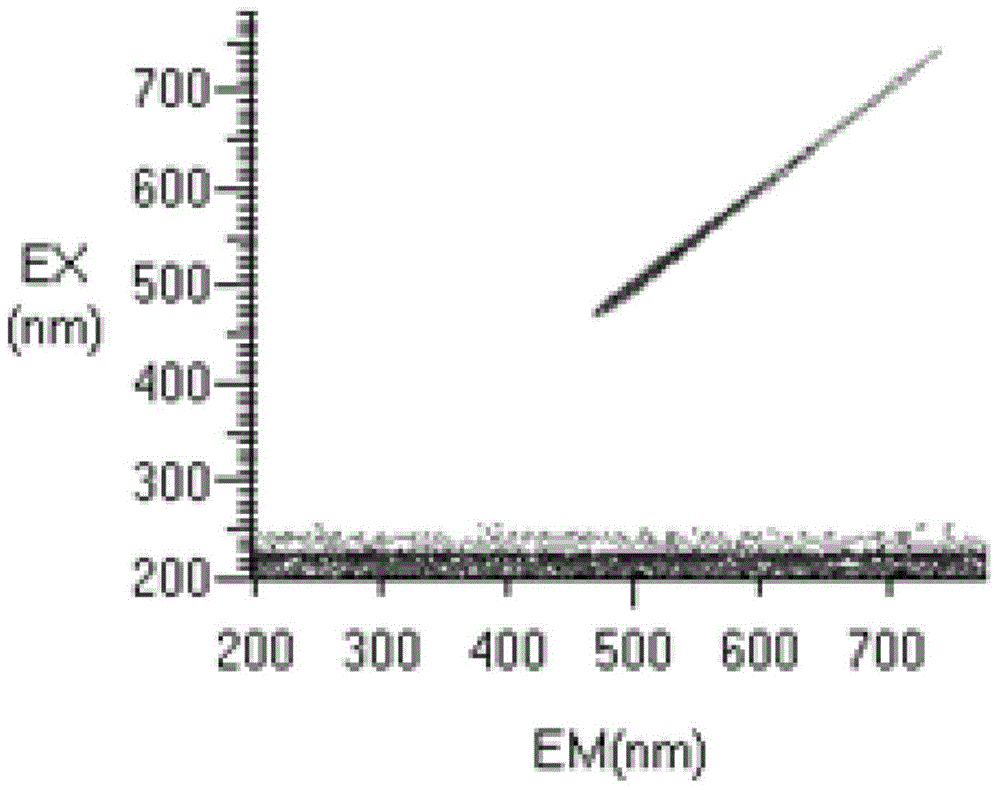

Image

Examples

Embodiment

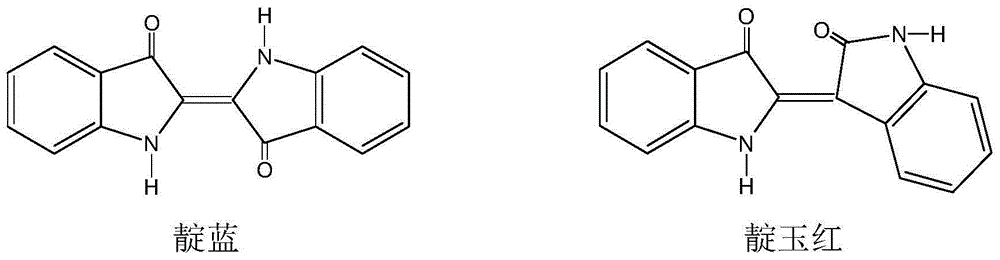

[0034] (1) Indigo dyeing: first get natural indigo dye and silk fabric, adopt vat dyeing method, dyeing process and formula are as follows table 1:

[0035] Table 1 Natural indigo dyed silk fabric process and formula

[0036]

[0037] (a) Reduction: First determine the bath ratio as 1:50, then accurately weigh 5% (o.w.f) of natural indigo dye, Na 2 S 2 o 4 0.8g / l, NaOH 0.6g / l, add natural indigo dye into the dyeing cup, and add a small amount of water to mix thoroughly; then add 2 / 3 of NaOH to the dyeing cup 2 S 2 o 4 , 2 / 3 of NaOH and 1 / 3 of water, the amount of dyeing bath is 1 / 3 at this time;, control the initial temperature in the dyeing cup to 40°C, then gradually increase the temperature to 50°C, and dry the vat at 50°C Reduction for 10min; then add remaining 1 / 3NaOH, 1 / 3Na 2 S 2 o 4 and 2 / 3 of water, and dry the tank at 50°C for 20 minutes to obtain a transparent yellow-green dyeing bath.

[0038] (b) Oxidation: take 2.0g of silk fabric and dip-dye it comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com