Optimal Control Method Based on Mechanical Ventilation Volume of Long Vertical Enclosed Busbar

A closed bus, mechanical ventilation technology, used in general control systems, adaptive control, control/regulation systems, etc., can solve the problem that IPB cannot fully meet the heat dissipation requirements, and achieve the effect of ensuring temperature difference requirements and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with specific examples.

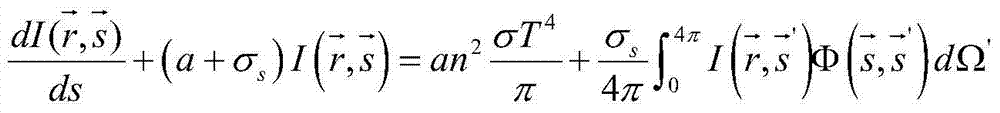

[0019] 1. Heat balance in IPB shaft

[0020] The heat dissipation of the IPB conductor is carried out through heat radiation between the conductor and the shell and air convection inside the shell, while the shell mainly dissipates heat through heat radiation and convection of air outside the shell. Thermal radiation is determined by the emissivity coefficient (which is a constant), and there is no difference in the vertical direction of the IPB. Therefore, it is mainly the convection of the internal and external air of the IPB that affects the temperature distribution of the IPB in the vertical direction.

[0021] P M =Q MF +Q MD

[0022] P M +P K =Q KF +Q KD

[0023] P M is the power loss of the conductor, W / (m phase);

[0024] Q MF Radiation heat dissipation for IPB to the shell;

[0025] Q MD For convective heat transfer between the conductor and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com