Antimony compound doping method of cigs

An antimony compound and compound technology, applied in the field of solar thin film cells, can solve the problems of poor Sb diffusion uniformity, high cost, solution loss, etc., and achieve the effects of easy control of doping amount, improvement of light-to-electricity conversion efficiency, and reduction of volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

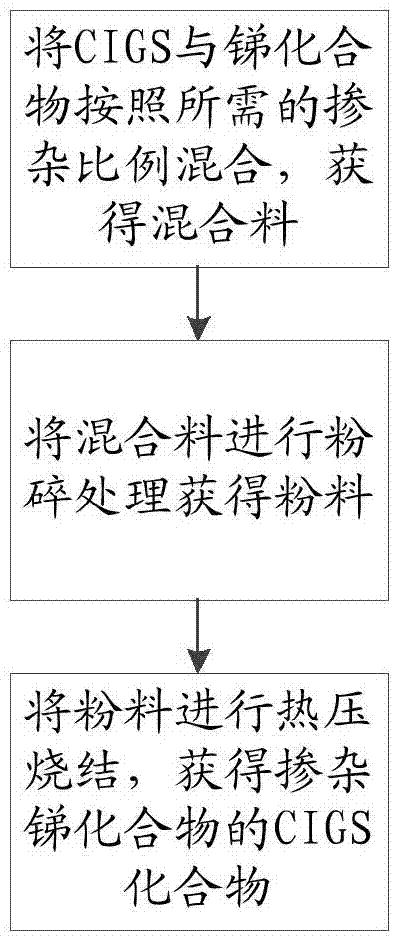

Method used

Image

Examples

Embodiment 1

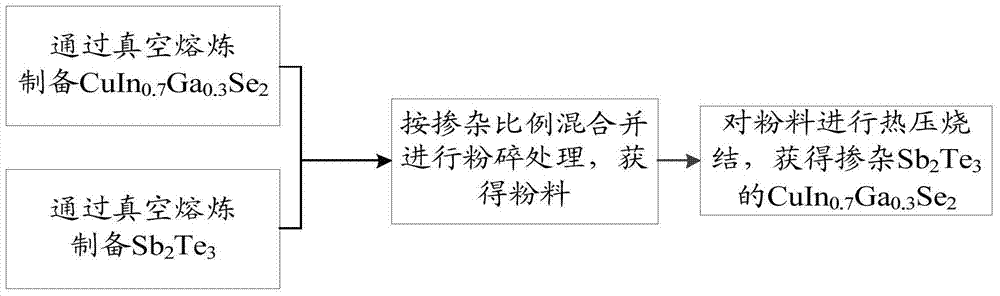

[0040] This embodiment provides a CuIn 0.7 Ga 0.3 Se 2 Doped with 1at% Sb 2 Te 3 method, which includes the following steps:

[0041] Step 1, preparing CIGS compound.

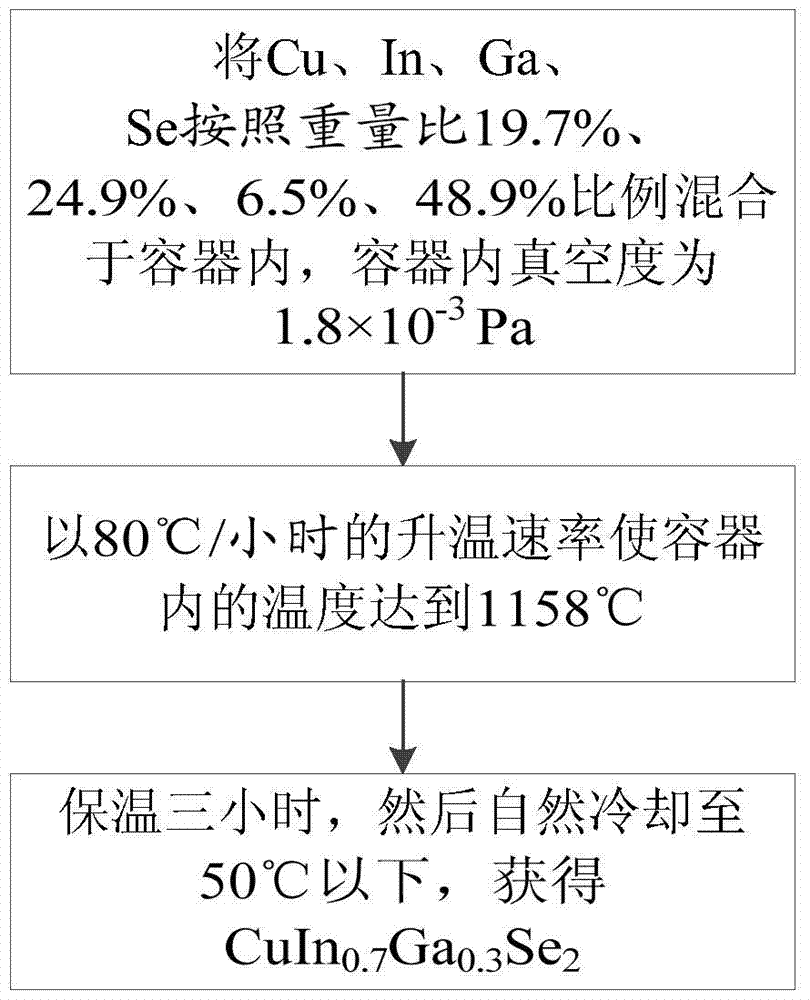

[0042] First, Cu, In, Ga, and Se are weighed according to the weight ratio of 19.7%: 24.9%: 6.5%: 48.9%. In order to improve the quality of CIGS products, Cu, In, Ga, and Se all use ≥99.99% purity. Preferably, Cu, In, Ga, Se are all pulverized so that they can be well mixed.

[0043] Secondly, place the above four components in a container so that the vacuum in the container reaches 1.8×10 -3 Pa, and then keep the container in a closed state. The container is preferably a high-purity quartz tube.

[0044] Again, put the container into a heating device for heating. In this embodiment, the heating device adopts a resistance heating furnace. The container was heated at a rate of temperature increase of 80°C / hour to bring the temperature inside the container to 1158°C. When the vessel reached 1158°C, it ...

Embodiment 2

[0063] This embodiment provides a CuIn 0.6 Ga 0.4 Se 2 Doped with 4at% Sb 2 Te 3 method, which includes the following steps:

[0064] Step 1, preparing CIGS compound.

[0065] First, Cu, In, Ga, and Se are weighed according to the weight ratio of 20%: 21.6%: 8.8%: 49.6%. In order to improve the quality of CIGS products, Cu, In, Ga, and Se all use ≥99.99% purity. Preferably, Cu, In, Ga, Se are all pulverized so that they can be well mixed.

[0066] Secondly, the above four components are placed in a high-purity quartz tube container, so that the vacuum degree in the container reaches 2.5×10 -3 Pa, and then keep the container in a closed state. Containers are preferably used.

[0067] Again, put the container into a heating device for heating. In this embodiment, the heating device adopts a resistance heating furnace. The container was heated at a rate of temperature increase of 80°C / hour so that the temperature inside the container reached 1169°C. When the vessel rea...

Embodiment 3

[0085] This embodiment provides a CuIn 0.7 Ga 0.3 Se 2 Doped with 2at% Sb 2 Se 3 method, which includes the following steps:

[0086] Step 1, preparing CIGS compound.

[0087] Firstly, Cu, In, Ga, Se with purity ≥ 99.99% are weighed according to the weight ratio of 19.7%: 24.9%: 6.5%: 48.9%.

[0088] Secondly, place the above four components in a container so that the vacuum in the container reaches 1.8×10 -3 Pa, and then keep the container in a closed state.

[0089] Again, put the container into a heating device for heating. In this embodiment, the heating device adopts a resistance heating furnace. The container was heated at a rate of temperature increase of 80°C / hour to bring the temperature inside the container to 1158°C. When the vessel reached 1158°C, it was held at that temperature for 3 hours to allow the components to react. While maintaining a high temperature of 1158 ° C, the container is constantly vibrating at a frequency of 0.5 Hz, so that the componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com