Structural coatings with dewetting and anti-icing properties, and processes for fabricating these coatings

A coating, pre-coating technology, applied in chemical instruments and methods, coating, transportation and packaging, etc., can solve problems such as non-durability of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

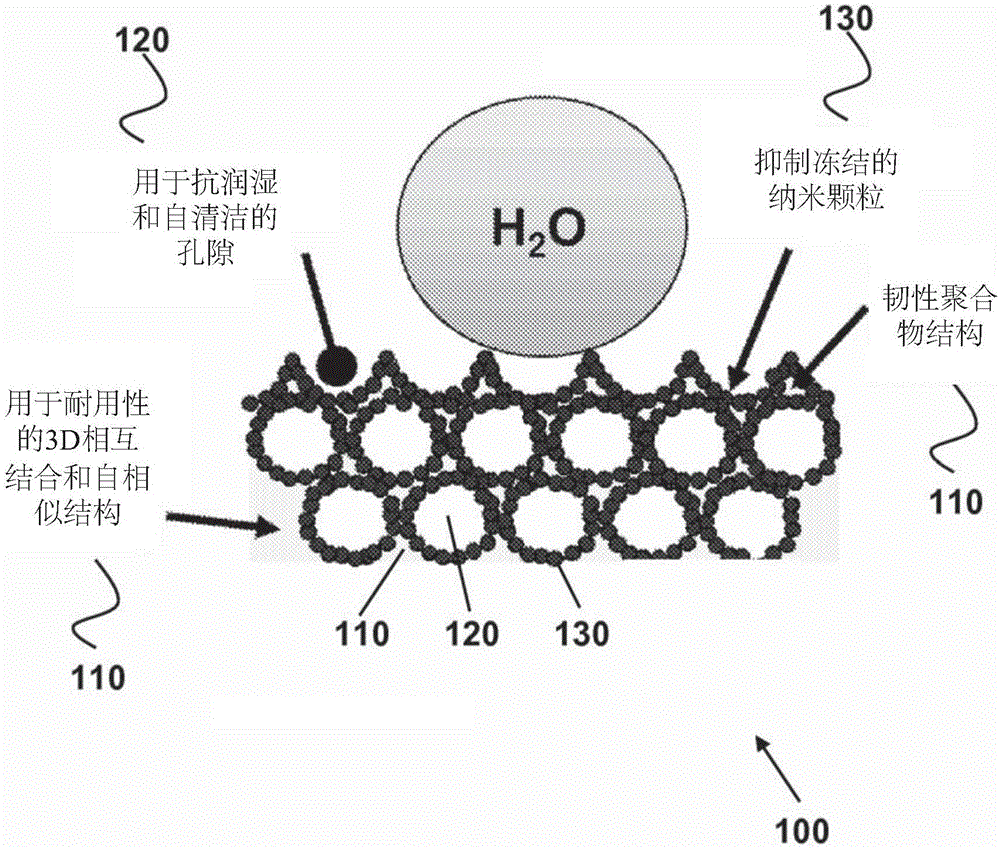

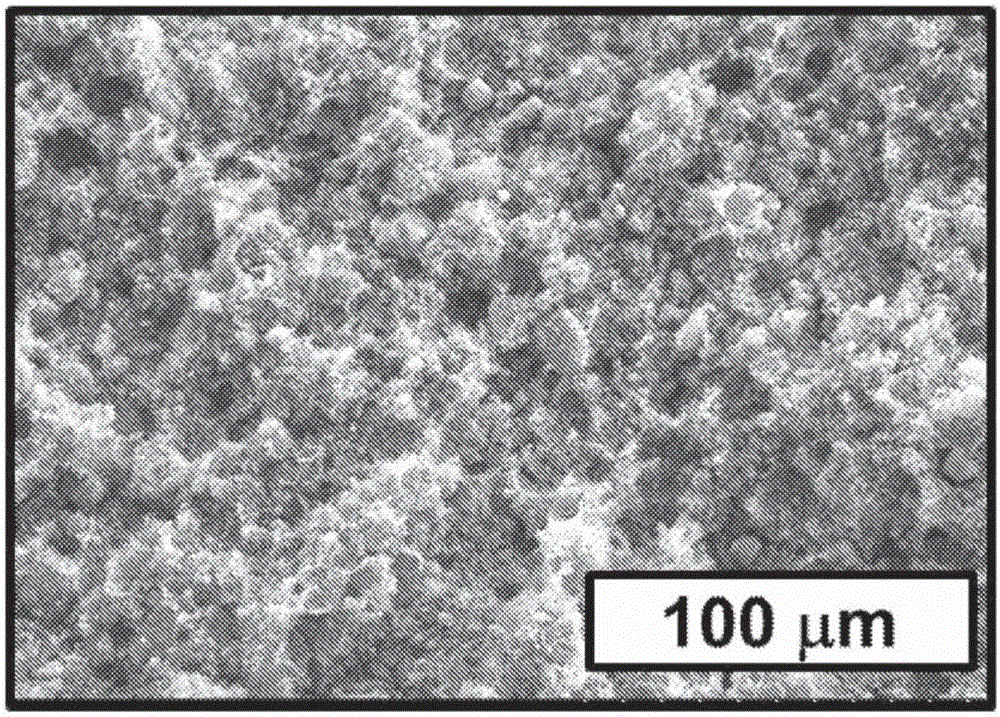

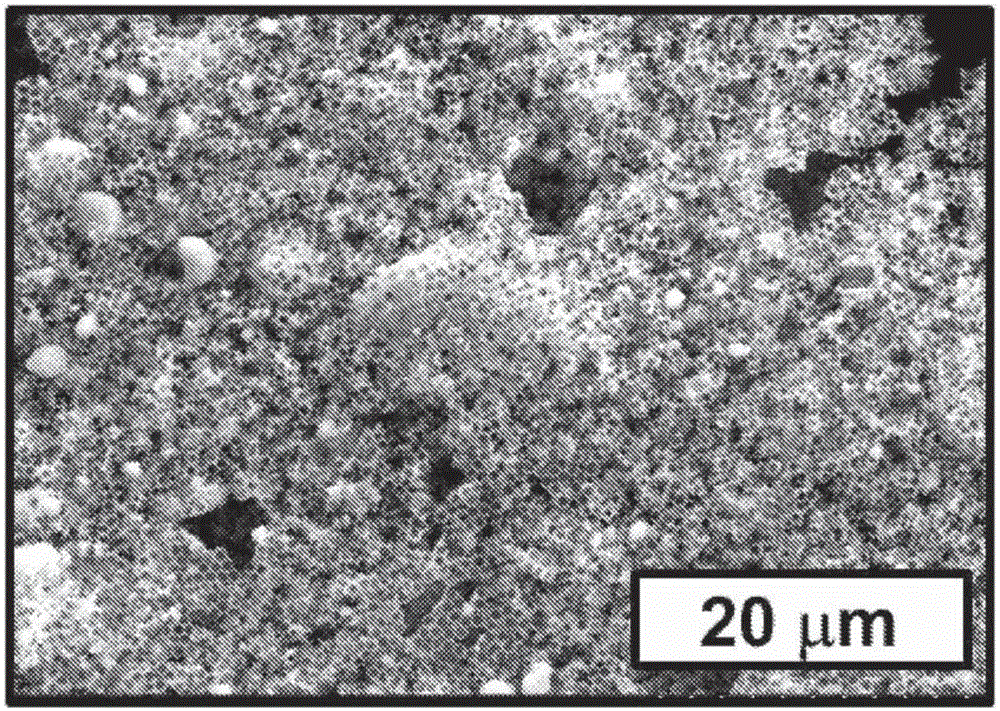

[0151] This Example 1 demonstrates a urea-formaldehyde based anti-icing coating using polystyrene discrete templates and hexamethyldisilazane-treated silica nanoparticles. DAP The plastic resin glue is a product of DAP Corporation (Baltimore, Maryland, US). Hexamethyldisilazane-treated silica was obtained from Gelest Inc. (Morrisville, Pennsylvania, US). TritonX-100 was provided by Sigma-Aldrich (St. Louis, Missouri, US). Polystyrene colloids of 500 nm diameter were obtained from Bang's Laboratory (Fishers, Indiana, US).

[0152] Silica (320 mg) treated with hexamethyldisilazane was combined with DIH 2O (1.0g) was loaded into a 50mL plastic centrifuge tube. TritonX-100 (60 mg) was then added and the mixture was vortexed for 1 minute to evenly disperse the silica in the fluid. In a separate 15mL plastic centrifuge tube, weigh DAP powder (1.0g) and with DIH 2 O combination, then transferred to a mixture of silica and water. The vessel was rinsed with additional water (...

example 2

[0157] The wetting resistance of the coating of Example 1 was evaluated by measuring the contact angle between water and the coating. This data is in Figure 4 shown in . Figure 4 The upper image of , depicts the contact angle between water and the coating of Example 1. Figure 4 The bottom table of , shows the contact and rolling angles of the aluminum substrate, the polymer, and the polymer+silica as different controls for the behavior of the substrate and the behavior of the non-porous coating material, respectively.

[0158] The coating of Example 1 exhibited a contact angle of about 150° and a rolling angle of less than 10°. Only the coating with template porosity (Example 1) showed a large contact angle with a small rolling angle, and thus poor water wettability, which is desirable for a coating.

example 3

[0160] The freezing point depression of the coating of Example 1 was measured. The data is in Figure 5 , which indicates the freezing point of water droplets on the coating of Example 1 compared to the control. The aluminum substrate and polymer+silica are controls for the behavior of the substrate and the behavior of the non-porous coating material, respectively.

[0161] Only the coating with templated porosity and exposed nanoparticles (the coating of Example 1) showed a significantly lower water freezing temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com