A light oil product desulfurizer based on supramolecular inclusion complexation and its application method

A light oil product and desulfurizer technology, which is applied in chemical instruments and methods, refined hydrocarbon oil, petroleum industry, etc., can solve the problem that light oil product desulfurization technology is difficult to meet the sulfur standard, and achieve good removal of sulfide Performance, ease of use, and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

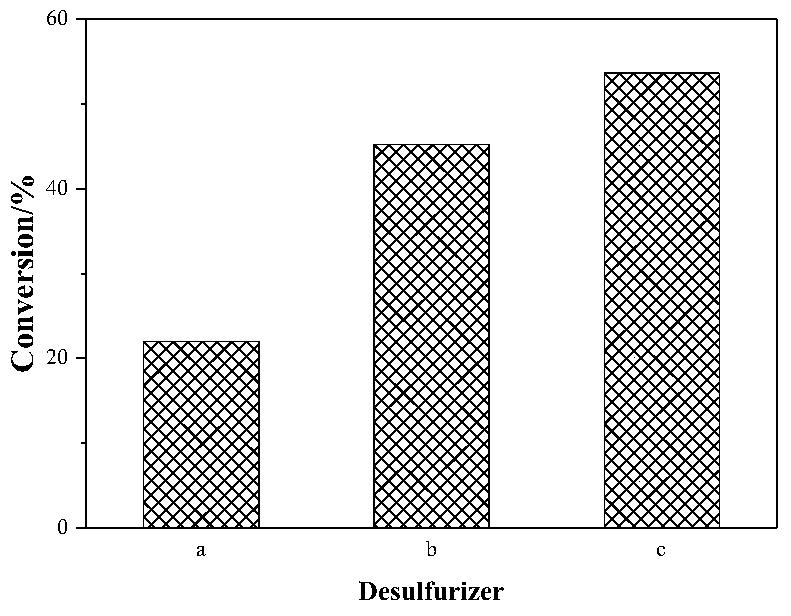

Embodiment 1

[0033] (1) beta-cyclodextrin is dissolved in the NaOH solution that mass concentration is 1%, and the quality of described beta-cyclodextrin is 0.1% of the NaOH solution quality, is heated under the condition of 20 ℃ and constantly stirs, makes The β-cyclodextrin dissolves;

[0034] (2) Mix FCC gasoline containing a certain concentration of sulfide with 1% NaOH solution containing 0.1% β-cyclodextrin according to a certain ratio of agent to oil;

[0035] Wherein the sulfide is n-butylmercaptan, and the sulfur concentration of the sulfide is 107 μg·g -1 , the agent-to-oil ratio is 1:5;

[0036] (3) Heating the mixed solution in step (2) at 20° C. and stirring continuously for 30 min, at this time, the removal rate of sulfide was 25.0%.

Embodiment 2

[0038] (1) beta-cyclodextrin is dissolved in the NaOH solution that mass concentration is 3%, and the quality of described beta-cyclodextrin is 0.3% of the NaOH solution quality, is heated under the condition of 20 ℃ and constantly stirs, makes The β-cyclodextrin dissolves;

[0039] (2) Mix FCC gasoline containing a certain concentration of sulfide with a 3% NaOH solution containing 0.3% β-cyclodextrin according to a certain ratio of agent to oil;

[0040] Wherein the sulfide is n-butylmercaptan, and the sulfur concentration of the sulfide is 107 μg·g -1 , the agent-to-oil ratio is 1:5;

[0041] (3) The mixed solution in the step (2) was heated at 20° C. and stirred continuously for 60 min, at which time the removal rate of sulfide was 58.6%.

Embodiment 3

[0043] (1) beta-cyclodextrin is dissolved in the NaOH solution that mass concentration is 3%, and the quality of described beta-cyclodextrin is 0.5% of the NaOH solution quality, is heated under 25 ℃ of conditions and constantly stirs, makes The β-cyclodextrin dissolves;

[0044] (2) Mix FCC gasoline containing a certain concentration of sulfide with a 3% NaOH solution containing 0.5% β-cyclodextrin according to a certain ratio of agent to oil;

[0045] Wherein the sulfide is thiophenol, and the sulfur concentration of the sulfide is 40 μg·g -1 , the agent-to-oil ratio is 1:5;

[0046] (3) The mixed solution in the step (2) was heated at 25° C. and stirred continuously for 30 min, at which time the removal rate of sulfide was 69.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com